Alpine Lock & Safe Co. Catalog 1890

Alpine Lock & Safe Co. Catalog 1890.

161 15 7MB

English Pages 23 Year 1890

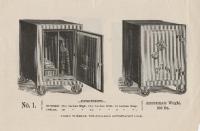

AlpineSafe&Lock1890s_0001

AlpineSafe&Lock1890s_0002

AlpineSafe&Lock1890s_0003

AlpineSafe&Lock1890s_0004

AlpineSafe&Lock1890s_0005

AlpineSafe&Lock1890s_0006

AlpineSafe&Lock1890s_0007

AlpineSafe&Lock1890s_0008

AlpineSafe&Lock1890s_0009

AlpineSafe&Lock1890s_0010

AlpineSafe&Lock1890s_0011

AlpineSafe&Lock1890s_0012

AlpineSafe&Lock1890s_0013

AlpineSafe&Lock1890s_0014

AlpineSafe&Lock1890s_0015

AlpineSafe&Lock1890s_0016

AlpineSafe&Lock1890s_0017

AlpineSafe&Lock1890s_0018

AlpineSafe&Lock1890s_0019

AlpineSafe&Lock1890s_0020

AlpineSafe&Lock1890s_0021

AlpineSafe&Lock1890s_0022

AlpineSafe&Lock1890s_0023

Recommend Papers

File loading please wait...

Citation preview

HIGHESt·} AVAR8·} BY + MESAL IN COMPETITION WITH THE WORLDT

*

TO THS C6L6BRA T6P

~

*

S A F

L

p I

~

E

E

By the Centennial Exposition of the Ohio Valley and Central States, at Cincinnati, Ohio, 1888.

NOTHING

* SUCC66PS * LIK6 * SUCCSSS!

Our Own Patents T Lowest Prices T Our Own COl1lbination Our Own Factory T Largest Sale T LJCK:S, Non-PicK:able I Equaled by None T Superior to All ~ SIXTH ST. PRINTING WORKS, 115 E. 6TH ST., CIN., O.

HINTS ON THE

CONSTRUCTION OF SAFES , SO=CALLED FIRE=PROOF.

~

'W

E HAVE DISCARDED all false ideas and have substituted all improvements presented to our notice regardless of the consequent expense, provided it increased to any extent the security to be afforded, and have, as the result of our labor and exhaustive experiments, the most secure Safe extant, which we can offer to the public, without fear of contradiction, as the most complete Safe in material, construction and finish, and worthy their continued confidence, possessing, as it does, all the requisites for fire and damp-proof protection. We have made it our study to meet the wants of the public and supply them with Safes that will not only preserve their contents during the most protracted conflagration, but in practical, qaily use, will be found convenient and not liable to get out of order by inexpert management. In order to meet the first great requirement and obtain Safes that will stand the test of a long protracted fire, several materials have been experimented on, and it is generally conceded that whatever material is used for the filling of Fire-Proof Safes, should be a bad conductor of heat and contain a large amount of water; in order that the steam generated therefrom shall carry off the hp.at that otherwise would destroy the contents of the Safes. Plaster of Paris was the first material experimented on, for it was well known that when saturated with water it forms a tolerably hard mass containing a very large proportion of water which will become disengaged by the application of heat. Time has demonstrated that this material is defective. The filling composed of it fo!: Safes never becomes perfectly dry if much water has been absorbed, and it is not possessed of much strength to resist fracture. The first defect results in rendering the interior of the Safes constantly damp, especially if closed for any length of time, and the second permits their fracture in falling from a height during the ravages of fire. Several devices have been tried to prevent the dampness referred to. Plaster of Paris has been used dry in the form of powder; and, in order to obtain the water necessary, lumps of alum have been mixed with the dry plaster, under the impression that alum would supply all the water required. Again, tubes of thin metal filled with water have been inserted with the dry filling, sealed by a material that melts at or about the temperature of boiling water; bul all these