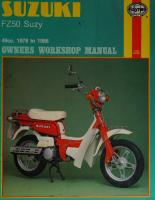

Haynes Suzuki FZ50 Suzy Owner's Workshop Manual 185010395X, 9781850103950

Haynes Suzuki FZ50 Suzy Owner's Workshop Manual - Martin Meek, Pete Shoemark - 1987.

123 29 11MB

English Pages 122 Year 1987

Recommend Papers

- Author / Uploaded

- Martin Meek

- Pete Shoemark

- Similar Topics

- Technique

- Transportation: Cars, motorcycles

File loading please wait...

Citation preview

FZ50 Suzy 49cc. 1978 to 1986

OW

THIS

BOOK SHOULD

his

BE RETURNED

anIBLCPR UB bSO ress

PHORM

wes

ON

Ns

OR

BEFORE

Aste

THE Ac

LATEST

DADO w

mw aweestenve

me8. 14--8 48

Wh F ORE LIBRARIES

AUTHOR |

|

Lancashire County S Council

THE LANCASHIRE LIBRARY. Library Headquarters, 143, Corporation St,

PRESTON PRI 2TB.

Suzuki

FZ50 Suzy Owners Workshop Mianual by Martyn Meek with an additional Chapter on the FZ50T, X, Z and D models

by Pete Shoemark Models FZ50 N. FZ50 T. FZ50 X. FZ50 Z. FZ50 D.

covered 49cc. UK 49cc. US 49cc. UK 49cc. UK 49cc. US

April 1979 to 1980, US October 1978 to 1979 only September 1979 to 1980 October 1980 to 1982, US October 1980 to 1981 1982 to 1986, US October 1981 to 1982 only October 1982 to 1983

ISBN 1 85010 395 X © Haynes Publishing Group 1980, 1983, 1986, 1987 All rights reserved. No part of this book may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopying, recording or by any information storage or retrieval system, without permission in writing from the copyright holder.

Printed in England (575-5M3)

British Library Cataloguing

Haynes Publishing Sparkford Nr Yeovil Somerset BA22 7JJ

Group

in Publication

Meek, Martyn Suzuki FZ50 Suzy owners workshop manual. —(Owners workshop manual).

England

Haynes Publications, 861 Lawrence Drive Newbury Park California 91320 USA

Inc

1. Suzuki motorcycle

|, Title ll. Shoemark, Pete 629.28'775 TL448.S8 ISBN 1-85010-395-X

Ill. Series

Library of Congress Catalog Card Number

87-80837

Data

02927214 Acknowledgements Our thanks are due to Fran Ridewood and Co, of Wells, Somerset who supplied the Suzuki FZ50 featured in the photographs throughout this manual. Special thanks are due to Heron-Suzuki (GB) Ltd who gave permission to reproduce their line illustrations, and to the technical Service Department of that Company who checked the manuscript for accuracy. We should also like to thank Huxhams Motorcycles of Poole who supplied service information. Alan Jackson gave valuable assistance with the stripdown

About

and rebuilding and devised the ingenious methods for overcoming the lack of manufacturer's service tools. Les Brazier took the photographs which accompany the text; Mansur Darlington edited the text. Finally, we would also like to thank the Avon Rubber Company, who kindly supplied advice on the tyre fitting and NGK Spark Plugs (UK) Ltd for advice on sparking plug conditians.

this manual

The purpose of this manual is to present the owner with a concise and graphic guide which will enable him to tackle any operation from basic routine maintenance to a major overhaul. It has been assumed that any work would be undertaken without the luxury of a well-equipped workshop and a range of manufacturer's service tools. To this end, the machine featured in the manual was stripped and rebuilt in our own workshop, by a team comprising a mechanic, a photographer and the author. The resulting photographic sequence depicts events as they took place, the hands shown being those of the author and the mechanic. The use of specialised, and expensive, service tools was avoided unless their use was considered to be essential due to risk of breakage or injury. There is usually some wav of improvising a method of removing a stubborn component, provided that a suitable degree of care is exercised. The author learnt his motorcycle mechanics over a number of years, faced with the same difficulties and using similar facilities to those encountered by most owners. It is hoped that this practical experience can be passed on through the pages of this manual. Where possible, a well-used example of the machine is chosen for the workshop project, as this highlights any areas which might be particularly prone to giving rise to problems. In this way, any such difficulties are encountered and resolved before the text is written, and the techniques used to deal with

them can be incorporated in the relevant section. Armed with a working knowledge of the machine, the author undertakes a considerable amount of research in order that the maximum amount of data can be included in this manual.

Each

Chapter

is divided

into numbered

sections.

Within

these sections are numbered paragraphs. Cross reference throughout the manual is quite straightforward and logical. When reference is made ‘See Section 6.10’ it means Section 6

paragraph

10 in the same

Chapter.

If another

Chapter were

intended the reference would read, for example, ‘See Chapter 2, Section 6.10’. All the photographs are captioned with a section/paragraph number to which they refer and are relevant to the Chapter text adjacent. Figures (usually line illustrations) appear in a logical but numerical order, within a given Chapter, Fig. 1.1 therefore refers to the first figure in Chapter 1.

Left-hand and right-hand descriptions of the machines and their components refer to the left and right of a given machine when the rider is seated normally.

Motorcycle

manufacturers

continually

specifications and recommendations,

make

changes

to

and these, when notified,

are incorporated into our manuals at the earliest opportunity. Whilst every care is taken to ensure that the information in this manual is correct no liability can be accepted by the author or publishers for loss, damage or injury caused by any errors in or omissions from the information given.

Contents Page

Acknowledgements

2

About this manual

2

Introduction to the Suzuki FZ50

5

Model dimensions and weight

5

Ordering spare parts

: |

Safety first!

;

Routine maintenance

7

8

Quick glance maintenance

Recommended

6

adjustments and capacities

lubricants

13

13

Working conditions and tools

15

Chapter

16

1 Engine, clutches and transmission

Chapter 2 Fuel system and lubrication

48

Chapter 3 Ignition system

60

Chapter 4 Frame and forks

68

Chapter 5 Wheels, brakes and tyres

78

Chapter 6 Electrical system

87

Chapter

7 The

FZ50T,

X, Z and D models

95

Wiring diagrams

102

Conversion factors

108

English/American terminology

109

Index

110

1980 Suzuki FZ50N

Close-up of Suzuki FZ50 engine/transm

Ission

uni

Introduction

to the Suzuki

The Suzuki FZ50 was introduced in 1978 to fill a small, but nonetheless important, gap in Suzuki's otherwise comprehensive range of powered two-wheeled machines. Its aim was to provide a cheap and easy to ride commuter machine, particularly for those people new to the pleasures of motor-

cycling. That there is a large, and ever increasing, market for this type of machine, can be judged from the success of a similar machine produced by Suzuki's major rival in the motorcycle market place. To be successful in selling this type of machine, Suzuki had to ensure that their fundamental design criterion was one of simplicity of construction, and therefore of maintenance and operation. To this end a simple two-stroke engine is employed using a clean and convenient separate lubrication system, and a fully automatic, two-speed transmission. The latter although fairly complex in construction is remarkably simple in operation. Furthermore the controls have been kept to a minimum to

enable former bicycle riders to adapt themselves to a motorised two-wheeler with the greatest possible ease. There are other benefits to be gained, for both novice and experienced riders alike, from the design of this machine. Perhaps most noteworthy from the long-term ownership aspect, is the complete enclosure of the final drive components. Due to the design of the transmission. the drive chain and sprockets are permanently lubricated, running as they do in the oil-filled transmission casing, and the chain is constantly maintained at the correct tension. This leads to a clean

operating machine, long component life, and does away with an unpleasant servicing task. Another worthy addition to ease maintenance chores is the fitting of an electronic ignition

FZ50

system to the US market FZ50 models. This system does away with the traditional contact breaker point arrangement, and ensures a healthy spark is always supplied at the correct moment. The cycle parts of the FZ50 also reflect the designers’ aim to appeal to a broad sector of commuters. Trying perhaps to tempt the already committted commuter away from the now well-established step-through type machines, and at the same time offering more to the first-time buyer in terms of weather protection than the traditional moped, the FZ50 is fitted with small legshields as standard equipment. Useful luggage racks are also provided at the front and rear of each machine; these may be supplemented by carrying baskets which can be purchased as optional equipment. Such items further enhance the machine’s appeal to a growing sector of the buying public — the housewife. If, as is the case in a growing number of situations, a busy or working housewife has to transport herself and assorted other items either to and from the local shops and/or her place of employment, and a car is not available, such a machine as the FZ50 provides a very practical solution. It also provides an attractive alternative to the increasingly expensive and erratic public transport systems. The Suzuki FZ50 is then a thoroughly practical, well designed and executed, and perhaps most importantly, an extremely economical little machine. This economy is shown right through its operation, from its almost miserly thirst for petrol and oil, to what should be an extremely slow rate of wear and tear on such items as tyres and brakes. In short, Suzuki have developed and marketed another winner in the FZ50. The FZ50 N is covered in Chapters 1 to 6 of this manual; for

information relating to later models see Chapter 7.

Model

dimensions and weight

Overall length

1650 mm (65.0 in)

Overall width

665 mm

(26.2 in)

Overall height

990 mm

(39.0 in)

Wheelbase

1120 mm (44.1 in)

Ground

120 mm

clearance

Dry weight

(4.7 in)

59 kg (130 Ibs)

Ordering spare parts When ordering spare parts for any Suzuki, it is advisable to deal direct with an official Suzuki agent who should be able to supply most of the parts ex stock. Parts cannot be obtained from Suzuki direct even if the parts required are not held in stock. Always, quote the engine and frame numbers in full, especially if parts are required for earlier models. The engine number is stamped on the leading face of the left-hand crankcase half adjacent to the cylinder barrel. The frame number is stamped on the right-hand side of the steering column beneath a detachable shroud. Use only genuine Suzuki spares. Some pattern parts are

available that are made in Japan and may be packed in similar looking packages. They should only be used if genuine parts are hard to obtain or in an emergency, for they do not normally last as long as genuine parts, even although there may be a price advantage. Some of the more expendable parts such as sparking plugs,

Frame number location

Engine number location

bulbs, oils and greases etc., can be obtained from accessory shops and motor factors, who have convenient opening hours, and can often be found not far from home. It is also possible to obtain parts on a Mail Order basis from a number of specialists who advertise regularly in the motorcycle magazines.

Safety First! Professional motor mechanics are trained in safe working procedures. Howevef enthusiastic you may be about getting on with the job in hand, do take the time to ensure that your safety is not put at risk. A moment's lack of attention can result in an accident, as can failure to observe certain elementary precautions. There will always be new ways of having accidents, and the following points do not pretend to be a comprehensive list of all dangers; they are intended rather to make you aware of the risks and to encourage a safety-conscious approach to all work you carry out on your vehicle.

Essential DOs and DON'Ts DON'T start the engine without first ascertaining that the transmission is in neutral. DON'T suddenly remove the filler cap from a hot cooling system — cover it with a cloth and release the pressure gradually first, or you may get scalded by escaping coolant. DON'T attempt to drain oil until you are sure it has cooled sufficiently to avoid scalding you. DON'T grasp any part of the engine, exhaust or silencer without first ascertaining that it is sufficiently cool to avoid burning you. DON'T allow brake fluid or antifreeze to contact the machine's paintwork or plastic components. DON'T syphon toxic liquids such as fuel, brake fluid or antifreeze by mouth, or allow them to remain on your skin. DON'T inhale dust — it may be injurious to health (see Asbestos

heading). DON'T allow any spilt oil or grease to remain on the floor — wipe it up straight away, before someone slips on it. DON'T use ill-fitting spanners or other tools which may slip and cause injury. DON'T attempt to lift a heavy component which may be beyond your capability — get assistance. DON'T rush to finish a job, or take unverified short cuts. DON'T allow children or animals in or around an unattended vehicle. DON’T inflate a tyre to a pressure above the recommended maximum. Apart from overstressing the carcase and wheel rim, in extreme cases the tyre may blow off forcibly. DO ensure that the machine is supported securely at all times. This is especially important when the machine is blocked up to aid wheel or fork removal. DO take care when attempting to slacken a stubborn nut or bolt. It is generally better to pull on a spanner, rather than push, so that if slippage occurs you fall away from the machine rather than on to it. DO wear eye protection when using power tools such as drill, sander, bench grinder etc. DO use a barrier cream on your hands prior to undertaking dirty jobs — it will protect your skin from infection as well as making the dirt easier to remove afterwards; but make sure your hands aren't left slippery. DO keep loose clothing (cuffs, tie etc) and long hair well out of the way of moving mechanical parts. DO remove rings, wristwatch etc, before working on the vehicle — especially the electrical system. DO’keep your work area tidy — it is only too easy to fall over articles left lying around. DO exercise caution when compressing springs for removal or installation. Ensure that the tension ig applied and released in a controlled manner, using suitable tools which preclude the possibility of the spring escaping violently. DO ensure that any lifting tackle used has a safe working load rating adequate for the job. DO get someone to check periodically that all is well, when working alone on the vehicle. DO carry out work in a logical sequence and check that everything is correctly assembled and tightened afterwards. DO remember that your vehicle’s safety affects that of yourself and others. If in doubt on any point, get specialist advice. IF, in spite of following these precautions, you are unfortunate

enough to injure yourself, seek medical possible.

attention

as soon

as

‘Asbestos Certain friction, insulating, sealing, and other products — such as brake linings, clutch linings, gaskets, etc — contain asbestos. Extreme care must be taken to avoid inhalation of dust from such products since it is hazardous to health. \f in doubt, assume that they do contain asbestos.

Fire Remember at all times that petrol (gasoline) is highly flammable. Never smoke, or have any kind of naked flame around, when working on the vehicle. But the risk does not end there — a spark caused by an electrical short-circuit, by two metal surfaces contacting each other, or even by static electricity built up in your body under certain conditions, can ignite petrol vapour, which in a confined space is highly explosive. Always disconnect the battery earth (ground) terminal before working on any part of the fuel or electrical system, and never risk spilling fuel on to a hot engine or exhaust. It is recommended that a fire extinguisher of a type suitable for fuel and electrical fires is kept handy in the garage or workplace at all times. Never try to extinguish a fuel or electrical fire with water.

Fumes Certain fumes are highly toxic and can quickly cause unconsciousness and even death if inhaled to any extent. Petrol (gasoline) vapour comes into this category, as do the vapours from certain solvents such as trichloroethylene. Any draining or pouring of such volatile fluids should be done in a well ventilated area. When using cleaning fluids and solvents, read the instructions carefully. Never use materials from unmarked containers— they may give off poisonous vapours. Never run the engine of a motor vehicle in an enclosed space such as a garage. Exhaust fumes contain carbon monoxide which is extremely poisonous; if you need to run the engine, always do so in the open air or at least have the rear of the vehicle outside the workplace.

The battery Never cause a spark, or allow a naked light, near the vehicle’s battery. It will normally be giving off a certain amount of hydrogen gas, which is highly explosive.

Always disconnect the battery earth (ground) terminal before working on the fuel or electrical systems. If possible, loosen the filler plugs or cover when charging the battery from an external source. Do not charge at an excessive rate or the battery may burst. Take care when topping up and when carrying the battery. The acid electrolyte, even when diluted, is very corrosive and should not be allowed to contact the eyes or skin. If you ever need to prepare electrolyte yourself, always add the acid slowly to the water, and never the other way round. Protect against splashes by wearing rubber gloves and goggles.

Mains electricity When using an electric power tool, inspection light etc which works from the mains, always ensure that the appliance is correctly connected to its plug and that, where necessary, it is properly earthed (grounded). Do not use such appliances in damp conditions and, again, beware of creating a spark or applying excessive heat in the vicinity of fuel or fuel vapour.

Ignition HT voltage A severe electric shock can result from touching certain parts of the ignition system, such as the HT leads, when the engine is running or being cranked, particularly if components are damp or the insulation is defective. Where an electronic ignition system is fitted, the HT voltage is much higher and could prove fatal.

Routine

maintenance

Refer to Chapter 7 for information relating to the FZ50T, X, Z and D models ’

Periodic routine maintenance

is a continuous

process that

begins immediately the machine is used. It must be carried out at specified mileage recordings or on a calendar basis if the machine is not used frequently, whichever is the sooner. Maintenance should always be regarded as an insurance policy, to help keep the machine in the peak of condition and to ensure long, trouble-free service. It has the additional benefit of giving early warning of any faults that may develop and will act as a safety check, to the obvious benefit of both rider and machine alike. The various maintenance tasks are described under their respective mileage and calendar headings. Accompanying diagrams are provided, where necessary. It should be remembered that the interval between the various maintenance tasks serves only as a guide. As the machine gets older or is used under particularly adverse conditions, it is advisable to reduce the amount between each check. Some of the tasks are described in detail, where si are not mentioned fully in the text. If a specific item is mentioned but not described in detail, it will be covered fully in the appropriate Chapter. No special tools are required for the iia routine maintenance tasks. The tools contained in the toolkit supplied with every new machine will prove adequate for each task, but

if they are not available, household should suffice.

the

tools

fourfd in the

average

Use a pocket pressure gauge for weekly tyre pressure checks

2

Engine oil level

Check the level of oil in the oil tank by viewing through the inspection window in the front of the tank. Replenish with a good quality two-stroke injector oil up to the upper level mark.

Weekly or every 150 miles (250 km)

3

7

clean. Note that in the UK it is an offence to use a vehicle on

Tyre pressures

Check the tyre pressures. Always check with the tyres cold, using a pressure gauge known to be accurate. It is recommended that a pocket pressure gauge is purchased to offset any fluctuation between garage forecourt instruments. The tyre pressures should be as follows: Front

Rear

18 psi (1.25 kg cm?)

21 psi (1.50 kg cm?)

At this juncture also inspect the actual condition of the tyres, ensuring there are no splits or cracks which may develop into serious problems. Also remove any small stones or other

small objects of road debris which may be lodged between the tread blocks. A small flat-bladed screwdriver will be admirable for this job. Examine the amount of tread remaining on the tyre. The manufacturer's recommended minimum tread depth is 1.6 mm (0.06 in). A tyre with a tread depth below this figure should be renewed.

Legal check

Check the operation of the electrical system, ensuring that the lights and horn are working properly and that the lenses are which the lights are defective. This applies even when the machine is used during daylight hours. The horn is also a statutory requirement.

Monthly or every 350 miles (500 km) Complete all the checks listed in the weekly/150 service, and then the following additional items:

1

mile

Battery electrolyte level

Check the battery electrolyte level. To gain access to the battery, pull free the larger of the two left-hand side panels; it is retained by four clips. If the electrolyte level does not lie between the upper and lower level marks on the battery,

replenish each cell with distilled water (not tap water). Do not overfill.

Routine maintenance a ee

2

Brake operation

Check the operation of the front and rear brakes. If required, adjust the cables so that there is about 20 — 30 mm (0.8 — 1.2 in) free play at each lever end before the brakes begin to operate. Before finalising the rear brake adjustment, the free play at the kick starter lifting lever must be adjusted. This is necessary due to the rear brake cable also being responsible for bringing the kick starter into operation via the kick starter lifting situated on the transmission casing. Adjust the free play at the lifting lever to 1 mm (0.04 in) by using the adjuster and locknut on the cable on the top of the transmission casing. Refer to the diagram accompanying the text in Chapter 1, Section 32.5. Both front and rear brakes are adjusted by means of a nut on the threaded extreme lower end of the operating cable. Turning the nut clockwise reduces the play, and vice versa.

3

Control cable lubrication

Apply a few drops of oil to the exposed lengths of inner cables at the tops of the various control cables.

ee

ee

Three monthly, or every 1000 miles (1500 km) Complete all the checks listed in the weekly/150 mile and monthly/350 mile service, and then the following additional items:

1

Sparking plug

Remove the sparking plug, using a proper sparking plug spanner, to avoid any risk of damage to the ceramic insulator. Examine the colour and condition of the electrodes, comparing this with the sparking plug condition chart in Chapter 3. This will give an indication of the general condition of the engine. Clean the plug electrodes using a wire brush and a small magneto file or fine emery cloth. If the outer electrode is thin, or the centre electrode has been eroded excessively, the plug must be renewed. The gap can be measured with a feeler

gauge, and should be between 0.6 — 0.8 mm in).

2

(0.024 — 0.031

Cleaning the air filter

Unscrew the air filter box cover screws and lift the cover away. Ease the foam filter element sleeve off the frame, taking care not to tear the foam material. The element should be cleaned thoroughly in a non-flammable solvent such as paraffin (kerosene) (do not use petrol), squeezing it gently to remove all traces of the oil and accumulated dust. Remove the solvent by squeezing the foam carefully and then allow the element to dry whilst the remainder of the solvent evaporates.

Kickstarter operating 1 2 3

mechanism

Kickstarter lifter lever Rear brake cam lever

Clearance of 1 mm

(0.04 in)

nipple

———a——

inner Cable

plasticine funnel around outer cable

cable suspended

_——___

Reimpregnate the element by immersing it in clean engine oil, squeezing out the excess so that the element is wet, but not dripping. Do not wring out the element because this will damage the foam, necessitating its renewal. If the element has become damaged or hardened with age it should be renewed as a matter of course.

3

Fuel filter cleaning

A fuel filter is fitted to the bottom of the petrol tap. The filter is located in a sediment ‘bowl’ attached to the bottom of the petrol tap by the threaded part of the ‘bowl’. The filter prevents rust, scale, water and other impurities from finding their way into the carburettor by straining the petrol as it passes through the tap. To ensure that the fuel flow remains unimpaired, the filter should be removed periodically and any debris removed from the filter. This is a simple operation. Using a spanner, preferably a ring spanner, of the correct size, unscrew the sediment bowl. Prior to this, ensure the fuel tap lever is in the ‘ON’ or ‘RES’

position. There is no need to drain the contents of the petrol tank if this precaution is observed. Clean the filter in petrol, using a soft bristle brush to loosen any deposits of rust, paint etc. The filter should be renewed if it is damaged. Clean out any sediment trapped in the bottom of the bowl. If the gasket on the sediment bowl is damaged it too should be replaced, otherwise a slight but persistent fuel leak will result.

vertically

Six monthly, or every 3000 miles (4500 km) Complete all the checks listed under the previous time/mileage headings and then carry out the following.

————"

cable lubricated when oil drips from far end

Oiling control cables

1

Contact breaker points: adjustment: UK models

Detach the flywheel generator cover from the right-hand side of the machine so that access may be made to the contact breaker assembly. Remove the sparking plug. Rotate the engine, by turning the flywheel until the contact breaker points are in the fully open position. The points can be viewed through the apertures in the flywheel face.

Routine

10

maintenance eer

_———

eee

L

L

Check that the point faces are not excessively burnt or pitted. If they are, remove the assembly as described in Section 7 of Chapter 3. If the contacts are in good condition, measure the gap using a feeler gauge. A 0.35 mm (0.014 in) gauge should be a light sliding fit — the points must be within the range: 0.3 — 0.4 mm in). Should they require adjustment, slacken the (0.012 — 0.016 securing screw just enough to permit the fixed contact to be moved, using a small screwdriver. Tighten the securing screw and then recheck the gap. The point at which firing occurs is dependent on the contact breaker gap. Because of this, if contact breaker adjustment is made the ignition timing must be checked as a matter of course to determine whether it is still accurate.

2

Ignition timing — UK models The ignition timing should be checked only after the contact

breaker gap has been checked and if necessary adjusted, for the reasons given in the preceding maintenance item. Ignition timing is checked by determining the point at which the contact breaker gap opens in relation to the position of the piston. To aid this, a timing mark is scribed on the periphery of the generator rotor and an index mark, in the form of a pointer, will be found on the periphery of the generator rotor housing in the 11 o'clock position. Unfortunately, the position of the rotor mark may not be very accurate and, therefore, prior to checking the ignition timing for the first time, the accuracy of the mark

must be determined. Required for this test will be a dial test indicator (DTI) and an adaptor to allow the DTI to be mounted in the sparking plug hole. Fit the DTI and rotate the flywheel rotor until the piston is indicated as being at TDC, i.e. with the DTI showing the highest reading. Zero the DTI and then rotate the flywheel rotor about 45° in an anti-clockwise direction. Now, slowly turn the rotor clockwise until the piston position is exactly 1.41 mm (0.055 in) BTDC. It is at this position that firing should occur, and consequently the rotor mark should be in exact alignment with the fixed index mark. If this is not the

3

Ignition timing — US models

The Suzuki FZ50 model available in the USA is fitted with an ignition system of the capacitor discharge (CDI) type. This system is entirely electronic, dispensing with the mechanical contact breaker unit and operating cam. Because no mechanical, wearing, components are fitted the progressive change in ignition timing experienced with mechanical systems is not found and thus periodic checking and adjustment should not be

necessary.

4

Carburettor adjustment

Carburettor adjustment should be carried out with the machine on its centre stand and the engine at normal operating temperature. A throttle stop screw and pilot air screw are provided on the left-hand side of the carburettor, that is, the side facing towards the rear of the machine, to allow an even idling speed to be obtained. It should be noted at this juncture, that the throttle cable adjustment should be checked, and if necessary readjusted, before the carburettor receives attention. The throttle cable should be adjusted using the cable adjuster and locknut under the rubber boot on the top of the carburettor. The free play in the cable should be adjusted to 0.5 — 1.0 mm (0.02 — 0.04 in). It is also worth noting that the choke operating cable, alongside the throttle cable on the carburettor, should also be adjusted to the same free play, in the same manner. Refer to the accompanying diagram. Start the engine and, using a screwdriver, turn the pilot air screw until the highest possible tick-over speed is obtained. Experimentation should be made by first turning the screw one way and then the other. When the correct position is established, reduce the tick-over speed by turning the throttle stop screw anti-clockwise, until the engine is running at about 1500 rpm. The recommended tick-over speed is between 1350 and 1650 rpm.

case make a new scribe mark on the rotor periphery in exact alignment with the fixed index mark. Henceforth disregard the old mark, using only the new mark for all subsequent timing

checks. To determine the exact moment of contact breaker opening a multimeter set on the resistance function should be interconnected with the contact breaker and the machine's wiring as follows: trace the leads which run from the generator to their snap connectors on the left-hand side of the machine below the battery, and separate the connector of the black/yellow wire. Connect on multimeter lead to the black/yellow wire, and the other lead to a suitable earth point on the engine. When the contact breaker opens the needle will register or change, from showing no resistance to showing some resistance. Rotate the generator rotor in a clockwise

direction until the timing mark on the rotor is aligned with the static index mark on the casing edge. If the ignition timing is correct the meter needle will deflect just as the two marks coincide. If the timing is incorrect adjustment must be made by means of the elongated holes in the stator plate through which the stator retaining screws pass. Rotation of the plate allows a limited amount of adjustment to be made. To gain access to the screws the generator rotor must be removed. This procedure is covered in Chapter 3.3, paragraph 5. After removal of the rotor, slacken the three stator retaining screws. The stator should be rotated by the amount that the rotor mark was misaligned from the fixed index mark. Tighten the retaining screws and push the rotor back onto the taper crankshaft end. Recheck the timing, carrying out further adjustments if required. It will probably take a number of attempts before the timing is accurate. After the final check, tighten the screws fully and refit the rotor. Before refitting the generator cover apply a few drops of light oil or a small amount of grease to the cam lubricating wick. Do not over-lubricate because there is a danger of excess

lubricant finding its way onto the points faces, causing ignition

malfunction.

Throttle cable adjustment 7

2 3

4

Adjusting screw Locknut Adjuster cover 0.5 — 1.0 mm (0.02 — 0.04 in)

Routine

11

maintenance

SS

5

Oil pump ‘adjustment

The amount of oil fed to the engine is strictly regulated by the adjustment of the oil pump control cable, which in turn is controlled by the throttle opening. For this reason the oil pump adjustment must be checked periodically, and whenever the throttle cable has been adjusted. To facilitate oil pump adjustment, a small amount of dismantling is necessary. Remove the air filter box cover from the right-hand side of the machine. It should now be possible to view the carburettor throttle valve through the centre of the air filter element support frame and through the carburettor intake. If vision is still difficult, remove the two crosshead screws from each end of the central tabbed retainer, and detach the air filter box, complete with foam element. An assistant will prove invaluable during the next step of the operation. Turn the throttle twist grip on the handlebar until the small circular index mark on the throttle valve can be seen. From there turn the twistgrip open until the index mark just touches the upper edge

of the intake (see accompanying

diagram). Switching to the

right-hand side of the machine (or instructing your trusty assistant to do so), with the throttle setting maintained, observe the setting of the oil pump control lever. If the small inscribed mark on the control lever js aligned with the index mark on the pump body, then adjustment is correct. It may well take more than one attempt to correlate throttle position, so that the throttle valve index mark is maintained in the correct position, whilst the pump setting is checked. If the marks on the pump are found not to be aligned, adjustment is made using the adjuster on the lower end of the pump control cable, where it passes through the upright cable guide.

Yearly or every 6000 miles (9000 km) Complete all the checks listed under the previous time/ mileage headings and then complete the following.

7

Changing the transmission oil

Place the machine on the centre stand and place a suitable container below the rear of the transmission. Locate and remove the hexagonal drain plug from the rearward end of the lower run of the transmission cover retaining screws. The drain plug is clearly marked to avoid any confusion. Allow the oil to drain completely into the container; remove the plastic filler cap from the top of the casing if the oil is reluctant to flow out swiftly. Note that this operation is facilitated if draining takes place after the machine has been on a run; the thinned lubricant will flow more easily. Check the condition of the sealing washer on the screw and then refit and tighten the screw. The new transmission oil must be poured in through the filler orifice at the top of the

transmission casing. Replenish with 0.8 litre (1.68/1.40 US/Imp pints) of SAE 20W/40 refilling is complete.

engine oil. Refit the filler cap when

Transmission oil drain and level plugs

Oil pump

adjustment 7

mark on throttle valve of carburettor

Indent on throttle valve

Oil pump 1 2

Air bleeding screw Cable adjuster

adjustment

3 4

Operating arm mark Index mark

os

“~

ha

Refill transmission casing as shown with SAE 20W/40 engine oil

12

2

Routine

maintenance

Decarbonising the engine

The cylinder head and cylinder barrel should be removed to allow removal of carbon deposits which will have built up in the combustion chamber and exhaust port. Reter to Chapter 1, Sections 18 and 19 initially although further information on this operation is to be found in other Sections in Chapter 1.

3

Cleaning the exhaust system Remove

and

clean

the exhaust

system

as described

in

Chapter 2, Section 12.

4

Steering head bearing adjustment Check the steering head bearings and if necessary adjust

them. Refer to Chapter 4, Section 7 for details.

5

Front and rear brake inspection

The front and rear wheels should be removed to allow inspection and cleaning of the brake shoes to take place. Refer to Chapter 5 Sections 3 and 4 for the front brake and Sections 8 and 10 for the rear brake and Section 11 of the same Chapter for correct adjustment of both brakes.

The cylinder head can be detached for decarbonising with the | engine still in situ as shown

Quick glance maintenance adjustments and capacities Engine oil tank CapaCity ...........c.cccceccsscsceesceseessceessescenesees

1.2 lit (2.54/2.12 US/Imp pint) Fill to within 1 in of filler neck top. Do not allow oil to fall below sight glass level

Transmission Oil Capacity .............ccccccessescecsseescssesseecssessseens

800 cc (1.68/1.40 US/Imp pint)

Contact breaker gap (UK model) .........cccccccsseseeeesssseseeees

0.3 — 0.4 mm

(0.012 — 0.016 in)

Sg

0.6 — 0.8 mm

(0.024 — 0.031

gS CNY fateFy a

ae ee re

RS

in)

Tyre pressures:

iene aed FGeal ete eee

ee erat sce MRP

eater ei ead: cr ran cancectaanca athanconte

Recommended

lubricants

Component

ERY TERY) se Sa eee ees

18 psi (1.25 kg cm’) 21 psi (1.50 kg cm’)

Type of lubricant

ES

ALEELS TSS OTA, ice

ONO

on

Pe

sect, IRON cocasorenestsansssteaseisenetocsconne

Good quality two-stroke oil

SAE 20W/40

Steering head bearingS ...........ccecscessssssseeseeseeseeseeseeeeeeeeenees

High melting-point grease

Wiheels

Dear itigsice peers ecee ccstasessssenes cost cvasse osviceestcessSecceosseausises

High melting-point grease

BSAKG aDIN Ol sneer cere eee ete cer tacos sreccrsccsonstsensctevensvscnacessureses

High melting-point grease

Cables etc (not nylon lime) ...... ccc seeseesseseseeteeteeseseseesees

Light machine oil

BlGctriCaltcOntacts cet

eree cient ssercccscursecceonacnseseeats=

WD4O

or similar water-dispersant spray

14

Castrol Lubricants Castrol Engine Oils Castrol Grand

Prix

Castrol Grand Prix 10W/40 four stroke motorcycle oil is a superior quality lubricant designed for air or water cooled four stroke motorcycle engines, operating under all conditions. Castrol TT Two

Stroke Oil

Castrol TT Two Stroke oil is a high quality lubricant specially formulated for both air and water cooled two stroke motorcycle engines. It is readily miscible with fuel and is designed to protect against malfunction of sparking plugs, build up of combustion chamber deposits, seizure and scuffing of pistons and exhaust port blocking. Castrol

R40

Castrol R40 is a castor-based lubricant specially designed for racing and high speed rallying, providing the ultimate in lubrication. Castrol R40 should never be mixed with mineral-based oils, and further additives are unnecessary and undesirable. A specialist oil for limited applications.

Castro! Gear Oils Castrol An treme

Hypoy EP90 SAE

90

pressure

mineral-based multi-purpose

Castrol Hypoy B EP80 and B EP90 Are mineral-based extreme pressure multi-purpose gear oils with similar applications to Castrol Hypoy, operating in average ambient temperatures between 90°F and 32°F. The Castro! Hypoy B range provides added protection for gears operating under very stringent service conditions.

exgear

Hypoy Light EP 80W

A mineral-based extreme pressure multi-purpose gear oil with simi-

lar applications to Castrol Hypoy but an SAE rating of 80W and suitable where the average ambient tem-

Girling

Limited

performance

and

surpasses

requirements

of

the the

current SAE J1703 Specification and the United States Federal Motor Vehicle Safety Standard No. 116 DOT 3 Specification. In addition, Castrol Girling Universal Brake and Clutch fluid fully meets the requirements of the major vehicle manufacturers. Castrol

Fork Oil

A specially formulated fluid for the front forks of motorcycles, pro-

viding

excellent

damping

and

load

carrying properties. Castrol

Chain

Lubricant

Castro! Greases Castrol

LM

Grease

A multi-purpose high melting point lithium-based grease suitable for most automotive applications, including chassis and wheel bearing lubrication. Castrol

MS3

BNS

Grease

A bentone-based non melting high temperature grease for ultra severe applications such as race and rally car front wheel bearings.

Castrol

Everyman

Oil

both household

use and cycle lubri-

cation. Castrol

DWF

A de-watering fluid which displaces moisture, lubricates and protects against corrosion of all metals. Innumerable uses in both car and home. Available in 400gm and

200gm

aerosol cans.

Castrol Easing Fluid

A rust releasing fluid for corroded nuts, locks, hinges and all mechanical joints. Also available in 250m tins.

Other Castrol Products Castrol Girling Universal and Clutch Fluid

A specially developed motorcycle chain lubricant containing nondrip, anti corrosion and water resistant additives which afford excellent penetration, lubrication and protection of exposed chains.

A light-bodied machine oil containing anti-corrosion additives for

Grease

A high melting point lithiumbased grease containing molybdenum disulphide. Suitable for heavy duty chassis application and some CV joints where a lithium-based grease is specified. Castrol

oil, primarily recommended for the lubrication of conventional hypoid differential units operating under moderate service conditions. Suitable also for some gearbox applications.

Castrol

peratures are between 32°F and 10°F. Also recommended for manual transmissions where manufacturers specify an extreme pressure SAE 80 gear oil. pi

Brake

A special high performance brake and clutch fluid with an advanced vapour lock performance. It is the only fluid recommended by

Castrol

Antifreeze

Contains anti-corrosion additives with ethylene glycol. Recommended for the cooling system of all petrol and diesel engines.

Working conditions and tools When a major overhaul is contemplated, it is important that a clean, well-lit working space is available, equipped with a workbench and vice, and with space for laying out or storing the dismantled assemblies in an orderly manner where they are unlikely to be disturbed. The use of a good workshop will give the satisfaction of work done in comfort and without haste,

where there is little chance of the and reassembled in anything other Unfortunately, these ideal working practicable and under these latter

machine being dismantled than clean surroundings. conditions are not always circumstances when im-

by a similar tool, during assembly, without a risk of damaging the screw heads. And, of course, it can be used again to retighten the screws, to ensure an oil or airtight seal results. Circlip pliers have their uses too, since gear pinions, shafts and similar components are frequently retained by circlips that are not too easily displaced by a screwdriver. There are two types of circlip pliers, one for internal and one for external circlips. They may also have straight or right-angled jaws. One of the most useful of all tools is the torque wrench, a

also be considered a good investment, a basic 2 in or $ in drive

form of spanner that can be adjusted to slip when a measured amount of force is applied to any bolt or nut. Torque wrench settings are given in almost every modern workshop or service manual, where the extent is given to which a complex component, such as a cylinder head, can be tightened without fear of distortion or leakage. The tightening of bearing caps is yet another example. Overtightening will stretch or even break bolts, necessitating extra work to extract the broken portions. As may be expected, the more sophisticated the machine, the greater is the number of tools likely to be required if it is to be kept in first class condition by the home mechanic. Unfortunately there are certain jobs which cannot be accomplished successfully without the correct equipment and although there is invariably a specialist who will undertake the work for a fee, the home mechanic will have to dig more deeply in his pocket for the purchase of similar equipment if he does not wish to

kit comprising a ratchet handle and a small number of socket heads, if money is limited. Additional sockets can be purchased, as and when they are required. Provided they are slim in profile, sockets will reach nuts or bolts that are deeply recessed. When purchasing spanners of any kind, make sure the correct size standard is purchased. Almost all machines manufactured outside the UK and the USA have metric nuts and bolts, whilst

employ the services of others. Here a word of caution is necessary, since some of these jobs are best left to the expert. Although an electrical multimeter of the AVO type will prove helpful in tracing electrical faults, in inexperienced hands it may irrevocably damage some of the electrical components if a test current is passed through them in the wrong direction. This can apply to the synchronisation of twin or multiple carburettors

those produced in Britain have BSF or BSW sizes. The standard

too, where a certain amount of expertise is needed when setting them up with vacuum gauges. These are, however, exceptions.

provisation is called for, extra care and time will be needed. The other essential requirement is a comprehensive set of good quality tools. Quality is of prime importance since cheap tools will prove expensive in the long run if they slip or break and damage the components to which they are applied. A good quality tool will last a long time, and more than justify the cost. The basis of any tool kit is a set of open-ended spanners, which can be used on almost any part of the machine to which there is reasonable access. A set of ring spanners makes a useful addition, since they can be used on nuts that are very tight or

where access is restricted. Where the cost has to be kept within reasonable bounds, a compromise

can be effected with a set of

combination spanners — open-ended at one end and having a ring of the same size on the other hand. Socket spanners may

used in the USA is AF, which is also found on some of the later British machines. Other tools that should be included in the kit are a range of crosshead screwdrivers, a pair of pliers and a hammer. When considering the purchase of tools, it should be remembered that by carrying out the work oneself, a large proportion of the normal repair cost, made up by labour charges, will be saved. The economy made on even a minor overhaul will go a long way towards the improvement of a tool kit. In addition to the basic tool kit, certain additional tools can prove invaluable when they are close to hand, to help speed up a multitude of repetitive jobs. For example, an impact screwdriver will ease the removal of screws that have been tightened

Some instruments, such as a strobe lamp, are virtually essential when checking the timing of a machine powered by CDI ignition system. In short, do not purchase any of these special items unless you have the experience to use them correctly. Although this manual shows how components can be removed and replaced without the use of special service tools (unless absolutely essential), it is worthwhile giving consideration to the purchase of the more commonly used tools if the machine is regarded as a long term purchase. Whilst the alternative methods suggested will remove and replace parts without risk of damage, the use of the special tools recommended and sold by the manufacturer will invariably save time.

Chapter 1 Engine, clutches and transmission Refer to Chapter 7 for information relating to the FZ50 T, X, Z and D models Contents Ger aliRG SSSR DO Geert vacates te ceee tastes ees eneseeeyeee taal Cena 1 Operations with the engine in the frame ........c ceeeeeeesesseaees 2 Method Of Engine rGInOVal nes-csasccecxessencécccesvewcus+arsaceaeeuepneitiers 8) Removing the engine/transmission unit from the frame ..... 4 Dismantling the engine: General ..........csccessseserecsseseccsssseeseeaes 5 Dismantling the engine: removing the cylinder head, bagrelEPISTOM FANG: _DISTOMBNGSIees eendas seecacts. rence eeunensbersiae 6 Dismantling the engine: removing the carburettor and inlet SHULD gather Pete ce res ace ee AEN cane ha antec 7 Dismantling the engine: removing the Oil PUMP .......cceeeeee 8 Dismantling the engine: removing the flywheel generator. 9 Dismantling the engine: removing the transmission GCASINGSG OVE) eth Some a, Chatter ODos, Eocene ene «a 10 Dismantling the engine: removing the clutches, transmission components and starter mechanism .............. Crankshaft assembly: checking prior to crankcase SE Pa ta tions trac esteess bie sean Ae eat arid a eee Dismantling the engine: separating the crankcase

halves and removing the crankshaft ......ccccccsssccsssessseessseesseeeees Examination and renovation: general Crankshaft assembly: examination and renovation ...........-.Connection rod and small-end bearing: examination ANT Fe OVEALIO Meare arte Sie eee oo Na Piston and piston rings: examination and renovation.......... Cylinder barrel: examination and renovation .....ssccseccseceseeeeeees

11

M2.

1S

16 17 18

Cylinder head: examination and renovation ......ccccccccceceseeeenee One-way clutch assembly: examination and renovation .....

19 20

Centrifugal clutches: function, examination and BEN OVALION 2 At. stdin cromtanepeecon se. ge teens ae ee Transmission components and drive train: examination ANG KEMOVATION SG.

GELMICOM Intern cetacean ete nt coe catia eats MELB CSAEC ILL alper acteatessocscxcerensiasettrcessastvastsacvenséesacvecqneseven suse? SBRVICOMIMD Uteccocincrvettnreseaucenstoscocstrenvasctesescrteerevestectnetiecactatas Spring free length (min): IOWaQ Gale CIULGhiyececnse racers feet tea ttaetsseccettsccseccorascrsvocteatesessene ATIC ASAT C EC Neerecaceessesscsanttc aexecexcsteectrontoneusetarsaevctouvsdeveasase Low gear clutch engageMent SPeEe ........scscsceeseeeseseesereees Low gear Clutch lock-Up SPEed «0... cscsssscssessessesseseessessesneees 2nd gear clutch gear Change SPEE .......ccsescsceeeeeeeeseessereees

87.000-87.15 mm (3.425-3.431 in) 87.40 mm (3.441 in) 105.00-105.15 mm (4.134—4.140 in) 105.50 mm (4.154 in) 28.0 33.0 2500 3800

mm mm rpm rpm

(1.06 in) (1.30 in) + 200 rpm + 200 rpm

21 kph (13 mph) + 2 kph (1 mph)

Transmission SUAS) [DGseeerereces toe emaetcete etre on csuasvassescosesesxncacevec vasuanaatneenasunsdaavasoas¥erastys nan VMbO GU CH OM ereeccteesercsccsevessetccveererrovers setereraneperanssacepnrcntsenenvas Biivall e UCOn iaecstecter cre cesceeccace ce seo Goree cass oust caccnsachatsenousesevessecanseds Gear ratios:

DN

1.

General

ACANCSO A eee

Pah nance areata oe sccsbecx Ge cesnacaszwaaussaanesro-pesccssadrse

description

The engine unit fitted to the Suzuki FZ50 models is a horizontal air-cooled, single cylinder two-stroke, employing a reed-valve in the induction system. The pressed-up full flywheel crankshaft is supported on two journal ball bearings and is housed in a two-piece crankcase which separates in the vertical plane. The connecting-rod big-end and small-end bearings are both of the caged needle-roller type. An aluminium alloy piston is used, working in a steel cylinder bore. Two piston rings are fitted; they are both of the keystone type, with a tapered crosssection, the second also having a separate expander band. All casings are manufactured in aluminium alloy. The righthand crankcase half is a simple casting, incorporating a recessed housing for the flywheel generator. The left-hand crankcase half casing extends rearwards to form a housing for the two clutches, the drive train and starter components. In addition the casing supports the rear wheel stub-axle and serves as the rear suspension swinging arm member. These machines are equipped with a fully automatic twospeed transmission system. Power from the engine is: trans-

Two-speed

automatic, chain final drive

1.000 : 1 8.696 : 1 Pole) 5-1 1.421: 1 DID 270H, 64 links

mitted from the left-hand end of the crankshaft through two separate automatic clutches which operate on the centrifugal principle, and select either 1st or 2nd gear as required. With the engine operating at low rpm, the low speed clutch engages. The power is then transferred to the 1st drive gear and then to the 1st driven gear. As the driven gear is forced to rotate, small engagement dogs ‘lock’ the gear to a secondary shaft (the intermediate shaft) which is then also forced to rotate. Fitted to the splined intermediate shaft is the forward chain final drive sprocket. When the speed of the engine increases, the second clutch engages. As the clutch begins to engage it forces the intermediate shaft to turn faster than the speed producec by the drive of the 1st driven gear assembly. This is accomplished by the use of a one-way of a one-way or free-wheeling clutch, also sometimes referred to as a sprag-type clutch, fitted to the inside of the 1st driven gear assembly. This one-way clutch is disengaged whenever the input speed of the inner section, which is driven by the intermediate shaft, is higher than that of the driven section of the outer gear pinion. The power can now be transmitted through the higher geared clutch number 2, to the shaft and its chain final drive sprocket. Power is transmitted from the intermediate shaft to the rear

18

Chapter 1 Engine, clutches and transmission ———_

ee

wheel stub-axle via a single-row drive chain. The drive chain is maintained at the correct tension by chain tensioners, in the form of short rubber blades, acting upon the upper and lower runs of the chain. Longevity of chain life is ensured by it being totally enclosed and immersed in the transmission oil.

Engine

starting

is provided

by a conventional

kickstart

arrangement, but a safety feature is incorporated that prevents engagement of the kickstart ratchet unless the rear brake is applied throughout the starting operation. When the brake is applied the cable also operates an interconnected lever which is mounted on the transmission casing. Through a series of levers the kickstart ratchet is freed, allowing it to slide along its mounting shaft and engage with the kickstart intermediate pinion which is mounted on the rear of the 2nd speed clutch. Engine lubrication is provided by a reservoir of two-stroke oil contained within a separate tank positioned in front of the petrol tank. The oil is injected into the crankcase by an enginemounted oil pump which is driven via a shaft from a crankshaftmounted pinion and controlled by a cable interconnected with the throttle. In this way the amount of oil passing into the engine is related to the engine speed and throttle opening. Lubrication is on the splash and gravity-feed principles. Those components which are housed in the transmission chamber are

lubricated by a separate chamber itself. 2

reservoir of oil contained

within the

Operations with the engine in the frame

With the exception of removal and replacement of the crankshaft and crankcase seals, all major operations may be

carried out with the engine/transmission These include the following:

unit in the frame.

Cylinder head removal and replacement Cylinder barrel and piston removal and replacement Flywheel generator removal and replacement Clutch(es), drive chain and gear removal and replacement Kick starter assembly removal and replacement Aahwh— Carburettor, oil pump and exhaust system removal and replacement Although engine removal is not strictly required, when a number of these operations are to be carried out at the same time it is worthwhile detaching the frame from the engine and wheeling it away forwards, leaving the engine/transmission unit supported on the centre stand and suitable, additional stands or blocks. This is a straight-forward operation which should take less then half an hour to complete.

eS 3

Method

Pe

of engine removal

— a

ee

1 In practice the engine is not removed from the frame: rather the frame is detached from the engine along with the rear wheel, followed by removal of the exhaust system and centre stand. The centre stand may be left in position during most procedures, to act as an engine stand, in conjunction with additional axle stands or wooden blocks. It should be noted at this point, that if only the top half of the engine, ie the cylinder head, exhaust pipe, cylinder barrel, piston and rings etc, is to be worked on, then removal of the footrest mounting bar and the hanger brackets each side will be beneficial. Removal of {wo mounting bolts from the top of each bracket will enable the

faotrest assembly

to be pulled clear.

eS 4

Removing

the engine/transmission

unit from the frame

ees

1 Place the machine securely on its centre stand, ensuring that there is no likelihood of it falling over during engine removal. Engine removal can be made much easier if the machine is raised about two feet by means of a stand. A stout table can be modified for this purpose, or alternati vely, a few substantial planks and some concrete blocks will suffice. This

procedure is by no means essential, but will greatly ease the discomfort of squatting or kneeling down to work. 2 Lift up the seat from the rear; it is held down simply by two suction pads. Remove the larger of the two side panels from each side of the machine; these simply pull off their retaining clamps. Remove the two small side covers, to expose the battery and electrical equipment on the left-hand side and the air cleaner assembly on the right-hand side. To detach the lefthand side cover, remove the two crosshead retaining screws, and pull the cover free. The right-hand cover incorporates the air-filter element. Remove the two crosshead screws and free the filter cover. This exposes the foam element and a central tabbed retainer through which two further screws pass. Remove the two screws and detach the tabbed retainer, foam element and filter housing. Disconnect the battery leads at the individual snap connectors. This will prevent inadvertent short circuit occurring when further disconnection of electrical components is carried out. If it is anticipated that the machine is to be out of service for an extended length of time, the battery should be, removed from the machine, and given a refresher charge at approximately one monthly intervals. See Chapter 6, Section 5 for details. 4 Place the petrol tap in the ‘ON’ or ‘RES’ position and detach the two petrol pipes from the stubs on the tap. Similarly, detach the fuel pipe and vacuum pipe from the carburettor spigots. A small screwdriver can be used to ease the pipes off without straining them. Each pipe is secured by a spring clip, the ears of which should be squeezed together as the pipe is pulled clear. 5 Disconnect the oil tank to oil pump feed pipe at the oil pump spigot. Be prepared to place a finger over the end of the pipe to stop temporarily the flow of lubricant. The pipe end may be plugged with a bolt or screw of suitable size, if care is taken not to damage the pipe, or the pipe end can be raised to a level

above that of the oil tank and then taped in. place against the frame tube or luggage rack.

6 Prise up the rubber boot from the two cables entering the top of the carburettor. Unscrew the top from the carburettor and withdraw the throttle valve complete with the carburettor top and throttle cable. Similarly, unscrew the choke housing from the top of the carburettor and withdraw the cable and choke plunger. Secure them to the frame so that they will remain clear of the engine. 7 Track the three (four on US models) leads up from the generator and disconnect them at the individual snap connectors at the base of the main frame tube. Disconnect also the main earth lead, held to the frame-mounted ignition coil by a single screw. Pull off the HT lead and plug cap from the plug and rest the lead, along with the choke and throttle cables, under the raised seat. 8 Remove the two bolts from the exhaust pipe flange at the exhaust port. Do not misplace the two lock washers. The complete exhaust system, comprising the one-piece downpipe and silencer unit and silencer heat shield, can be manoeuvred from position after unscrewing the single support bolt. This bolt, and its plain and lock washers, passes through a bracket welded to the forward end of the silencer and into a lug projecting from the rear of the right-hand crankcase. 9 To allow the rear brake cable to be detached it is necessary to remove the rear wheel. This will facilitate removal of the small plate which acts as a cable guide, mounted on the transmission casing. The plate is retained to the rear of the transmission casing by a countersunk cross-head screw which cannot easily be removed until the rear wheel is detached. To remove the rear wheel, simply pull out the split pin from the castellated wheel nut, and slacken and remove the nut and washer. Tip the machine forwards on the centre stand so that the rear wheel is clear of the ground and then slip it off the stub axle towards the right-hand side of the machine. Unscrew the

adjuster nut from the threaded end of the rear brake Operating

cable and then withdraw the cable from the trunnion. Displace the trunnion from the brake actuating arm and refit it and the adjuster nut on the cable to avoid loss. Pull the brake cable back, against the tension of the cable spring, and free it from the ~

Chapter

1 Engine, clutches and transmission

top of the actuating lever. The cable can now be pulled clear of the kickstart lifting lever projecting from the central part of the transmission

casing. Rest the now free brake cable under the

seat with the other detached cable to an adjacent

cables, or alternatively, tie the

part of the frame

so that it is clear of

further dismantling operations. 10 Remove the nut and washer from the right-hand end of the pivot shaft on which the engine is mounted. Leave the shaft in position at this stage. Detach the rear suspension unit from the top of the transmission casing by removing the single mounting bolt 11 Before extracting the pivot shaft, suitable blocks, or preferably axle stands of the correct height, should be positioned under the footrests. Support the weight of the frame assembly and drift out the pivot shaft. It should drift out easily; if it resists removal, a few taps with a soft-headed mallet should ease the shaft sufficiently for a firm grip to be obtained on the left-hand end, and it can then be pulled free. Once the shaft is clear of the frame, the engine will drop; this is not a problem, as the still attached centre stand will act as a temporary engine stand. 12 The help of an assistant will be beneficial during these final stages, particularly now that the front wheel and frame are free

to be separated from the engine/transmission unit. Remove the footrest supporting axle Stands or blocks, and wheel the frame and front wheel assembly away from the engine unit. As this is

being done support the transmission casing, with suitable wooden blocks or the axle stand(s) that were used to support the footrests. Take care when carrying out this operation that no pipes or cables are trapped or snagged. 13 As described in Section 2 of this Chapter the main engine and transmission components are now accessible without the need for removal of the centre stand. Only if crankshaft separation is required does the centre stand require removal. In many cases continued dismantling as described in the following paragraphs will be a matter of choice. 14

If attention to the transmission is required, the oil within the

transmission casing must be drained. Place a container of approximately 1 litre (13 pints) below the rear of the transmission casing. The drain plug serves also as one of the casing screws in the lower run. The bolt in question is clearly marked as such, and is the 2nd from the right-hand end of the casing. Remove the drain plug and its sealing washer and allow the oil to drain fully; removal of the plastic filler cap from the top of the casing will speed up oil flow rate. When draining is complete refit the drain plug and washer. 15 Position the engine on its side so that access may be made to the centre stand retaining bolts. Retract the stand carefully, taking care not to allow stray fingers to become trapped. Detach the two bolts that secure the stand to the engine and lift the assembly away.

3.1 If only dismantling engine top end, remove footrests and hanger brackets

a

oe

So

eatienen

this 4.8 With the rear wheel removed, access can be gained to

screw

19

4.10 Detach the lower end of the rear suspension unit

Chapter 1 Engine, clutches and transmission

20

41 1 Pull out pivot shaft to the left-hand side of machine

4.14 Remove this bolt to free complete exhaust system

5

precaution against pieces of broken piston ring or other dirt or debris entering the crankcase mouth, a piece of clean rag should be used to pack around the connecting rod, prior to the piston rings leaving the confines of the cylinder sleeve. 3 Remove the circlip from each piston boss, and discard it. Using a drift of the correct diameter, tap the gudgeon pin out of the piston boss until the piston complete with rings can be lifted off the connecting rod. Make sure that the piston is properly supported during this operation, to prevent the connecting rod from bending. 4 If the gudgeon pin is a particularly tight fit, the piston

Dismantling the engine: general

1. Before commencing work on the engine unit, the external surfaces should be cleaned thoroughly. A motorcycle engine has very little protection from road grit and other foreign matter, which will find its way into the dismantled engine if this simple precaution is not taken. 2

One of the proprietary engine cleaning compounds such as

‘Gunk’ or ‘Jizer’ can be used to good effect especially if the compound is allowed to penetrate the film of oil and grease before it is washed away. When washing down, make sure that water cannot enter the inlet or exhaust ports or the electrical system, particularly if these parts are now more exposed. 3 Never use force to remove any stubborn parts unless

specific mention is made of this requirement in the text. There is invariably good reason why a part is difficult to remove, often because the dismantling operation has been tackled in the wrong sequence.

6

Dismantling

the engine:

removing

the cylinder head,

barrel, piston and piston rings

pa 1 Slacken evenly and then remove the four nuts which secure the cylinder head in position. After displacing the nuts the cylinder head may be lifted from position. In the event of the cylinder head being stuck in position, a soft-headed mallet may be used to break the seal, by tapping lightly the cylinder head

around

the

mating

surface

area.

Discard

the cylinder

head

gasket; anew gasket must be fitted on reassembly to ensure a gas tight seal. 2 Lift the cylinder barrel carefully up along the studs, taking

care to catch

the piston

as it emerges

from the bore. As a

should be warmed first, to expand the alloy of the piston and release the grip on the steel pin. A convenient way of warming the piston is to place a rag soaked in hot water on the crown. 5 Note that the piston is marked with an arrow cast in the crown. This mark is a useful guide to ensure that the piston is refitted correctly, that is, with the arrow mark facing downwards towards the exhaust port. 6 The small-end bearing takes the form of a caged needle roller bearing. Displace the bearing from the small-end eye. 7 Note that the piston rings are pegged so that they will remain in a set position. This is important, otherwise the rings

will rotate whilst the engine is running, permitting the ends to become trapped in the ports and so get broken. 8 To remove the rings spread the ends sufficiently with the thumbs to allow each ring to be lifted clear of the piston. This is a very delicate operation which must be handled with great care.

9

Piston rings are brittle and they break very easily.

If the rings are stuck

in their grooves

or have

become

gummed by oily deposits, it is sometimes possible to free them by working small strips of tin along the back, to give a ‘peeling’

action. Note and remove the expander ring that is fitted behind the 2nd ring. Fig. 1.1 Cylinder head and cylinder

1 Z 4} 4 5 6

Cylinder head

Cylinder head gasket Nut — 4.off Damping block — 6 off Sparking plug Cylinder barre/

7 Cylinder base gasket 8 Stud — 4 off 9 Damping block — 10 off 10 Damping biock — 2 off

Chapter 1 Engine, clutches and transmission .

21

, Thin metal strips

6.1 Slacken and remove nuts, and lift cylinder head away

to remove the screws; their heads are of a normal hexagon type. As the forward left-hand screw on the flange is slackened, the

other end of the main earth (ground) lead can be disconnected. Fig. 1.2 Freeing gummed

rings

It will be remembered, that the other end of the lead has already

been separated from its location on the frame-mounted ignition coil. Note also the position of the generator cable securing clip held by the forward right-hand flange screw. Slacken the four screws evenly to avoid any possible distortion of the flange. With the two forward screws removed, detach the small plate which fits above the flange and which at its left-hand end, forms an upright oil pump control cable guide plate. 3. Displace the inlet stub and also the reed valve plate. When removing the plate, care should be taken not to damage the mating surfaces or the reed valve ‘petals’ themselves.

8

Dismantling

the engine: removing the oil pump

1. Slacken and remove the two crosshead screws which retain the oil pump to the crankcase. Grasp the oil pump and pull it up out of position until the oil pump drive shaft leaves the tunnel in which it fits. 2 A large washer fits over the oil pump drive shaft. Remove the washer and place it in a safe place to prevent its loss. Also remove the gasket from the pump mating surface.

6.2 Support the piston as it emerges from the bore

Se Dismantling 7 inlet stub

the engine: removing

the carburettor and

mEEEEE EE EEE ee

EIEIEE REE

1 «Remove the white plastic air filter box cover which is attached to the air filter box by two crosshead screws. Withdraw the foam element off its support frame. The filter box

is secured by two further screws passing through each end of a central tabbed retainer, and through the rear of the box into a bracket secured to the carburettor. Slacken and remove the two screws and lock washers which retain the inlet stub upper end to the air filter box support bracket. The carburettor can now be lifted away. Remove also the gasket fitted to the inlet stub flange where it mates with the carburettor intake. Disconnect the oil feed pipe to the inlet stub at the spigot 2 on the back of the stub. Slacken evenly and then remove the four screws which pass through the inlet stub lower flange into the crankcase. A variety of screwdrivers may be required during screw removal due to the difficult access to some of the screws. As a possible alternative, the correct sized spanner can be used

Ss

cae

8.1 Lift the oil pump clear of the crankcase

22

9

Chapter 1 Engine, clutches and transmission

Dismantling the engine: removing the flywheel gener-

ator 1 Remove the five crosshead screws from around the periphery of the circular cover on the right-hand side of the engine. Lift the cover and its sealing gasket from place. 2 The generator rotor is secured by a 17 mm nut, a lock washer and a plain washer on the end of the crankshaft. The nut is fitted on the threaded end of the crankshaft and is recessed in the centre of the rotor. The stator plate containing the two coils, the condenser and contact breaker points (UK model only) is fitted behind the rotor and is secured to the crankcase by screws. 3 To allow the rotor securing nut to be slackened without the rotor turning, it will be necessary to prevent the crankshaft from rotating. If this is to be done with the engine in situ, refer to paragraph 4 of this section. With the engine on the bench, and the procedures stated so far having been followed, a closefitting bar can be passed through the connecting rod small-end eye. The bar can be arranged to rest on two wooden blocks placed either side of the con-rod across the crankcase mouth. The bar should not be allowed to rest directly on the crankcase mating surface or damage could occur. 4 lf the previous procedures have not been followed, due to the operator not wishing to remove the top-end of the engine, then a different method of crankshaft rotation prevention must be applied. If the manufacturer's flywheel holding tool is

unavailable (Part No 09930-40113), then an alternative can be found in the strap or chain wrench passed around the rotor periphery. 5 Slacken and remove the rotor securing nut and the two washers. In the absence of the manufacturer's sliding hammer arrangement (sliding shaft, Part No. 09930-30102 and sliding

weights attachment, Part No. 09930-30161), some alternative method of drawing the rotor off its taper must be devised. The necessity for the rotor to be forcibly drawn or extracted from the

end of the crankshaft, is due initially to the rotor being a tapered fit on the crankshaft end and secondly because its key-way, in

the centre of the rotor, locates with a Woodruff

crankshaft end. Because variably be a tight fit.

of the foregoing,

key in the

the rotor will in-

6 The operation of drawing the rotor from position may be accomplished with a conventional two-legged puller. Before placing the puller in position, refit the rotor securing nut on the crankshaft end so that the outer face of the nut is flush with the threaded end of the crankshaft. This will help prevent damage to the shaft. If the rotor refuses to release from the tapered shaft, do not continue tightening the puller centre screw: this will only damage the shaft. With the screw tightened down, strike firmly the screw head with a hammer. This should release the rotor. On no account strike the rotor itself to try and aid its removal; damage can easily result. Note that during this operation care must be taken not to damage any internal component or connections on the stator plate, when the legs of the puller are inserted through the openings in the rotor face. It follows, therefore, that the thinner the legs on the puller, the less likelihood of damage there is going to be. If the rotor proves

particularly stubborn it is strongly recommended

through and the stator plate freed. Also free the leads from the guide clip attached to the carburettor inlet stub lower flange, if not done previously. 9 The generator rotor and stator plate should be stored in a safe place so that accidental damage is prevented. Care should be taken to ensure that metallic swarf does not adhere to the

rotor magnets. 10

Dismantling

the

engine:

removing

the

transmission

casing cover

1 If the transmission casing cover is to be removed with the engine unit still in situ, the transmission oil must first be drained. The oil drain bolt, which is clearly marked as such, also serves as one of the casing cover retaining bolts. The bolt in question is the 2nd from the right-hand end of the cover in the lower run. Prior to removing the drain bolt and its sealing washer, ensure a suitable receptacle is placed below the rear of the casing; the container should have a capacity of roughly 1