Precious Metal: German Steel, Modernity, and Ecology 9780271092454

With its incorporation into architecture on a grand scale during the long nineteenth century, steel forever changed the

202 104 147MB

English Pages 248 Year 2022

Recommend Papers

- Author / Uploaded

- Peter H. Christensen

File loading please wait...

Citation preview

P R E C I O U S M E TA L

PETER H. CHRISTENSEN

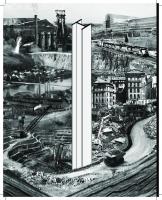

PRECIOUS METAL German Steel, Modernity, and Ecology

The Pennsylvania State University Press University Park, Pennsylvania

Library of Congress Cataloging-in-Publication Data Names: Christensen, Peter H., author. Title: Precious metal : German steel, modernity, and ecology / Peter H. Christensen. Description: University Park, Pennsylvania : The Pennsylvania State University Press, [2022] | Includes bibliographical references and index. Summary: “Explores the ecological interrelationship, mediated by steel, of artificial and natural habitats, with a focus on steel’s earlier history in architecture during the long nineteenth century”—Provided by publisher. Identifiers: LCCN 2021061863 | ISBN 9780271092317 (cloth) Subjects: LCSH: Building, Iron and steel—History—19th century. | Architecture, Modern—19th century. | Steel industry and trade—History—19th century. | Steel industry and trade—Germany—History—19th century. | Steel industry and trade—Environmental aspects—History—19th century. Classification: LCC NA4135 .C49 2022 | DDC 721/.04471—dc23/eng/20220224 LC record available at https://lccn.loc.gov/2021061863 Copyright © 2022 Peter H. Christensen All rights reserved Printed in China Published by The Pennsylvania State University Press, University Park, PA 16802–1003 The Pennsylvania State University Press is a member of the Association of University Presses. It is the policy of The Pennsylvania State University Press to use acid-free paper. Publications on uncoated stock satisfy the minimum requirements of American National Standard for Information Sciences—Permanence of Paper for Printed Library Material, ansi z39.48–1992.

Contents

List of Illustrations (vii) Acknowledgments (ix) Note on Translation and Format (x)

Introduction (1) 1 Origin (13) 2 Industry (39) 3 Production (83) 4 Dissemination (101) 5 Building (125) 6 Return (155) Conclusion (179)

Notes (185) Bibliography (199) Index (225)

Illustrations

1. King Tutankhamun’s iron dagger, ca. fourteenth century BC (5) 2. Iron Bridge at Coalbrookdale (7) 3. Oil on the surface of the sea during the Deepwater Horizon oil spill, August 2010 (8) 4. William Smith, “A Delineation of the Strata of England and Wales with Part of Scotland,” 1815 (15) 5. Leopold von Buch, “Geognostische Karte von Deutschland,” 1826 (16) 6. View of the “Concordiasee” in Oberhausen, ca. 1875 (20) 7. Diagram illustrating the effects of mining subsidence (21) 8. Map of the Ruhr Valley (Ruhrgebiet), 1830 and 1930 (25) 9. T. L. Dawes, Mining on the Comstock, 1877 (26) 10. Model depicting a prototypical nineteenth-century mine (29) 11. Children working in a mine in a side tunnel with airlock, drawing from 1844 (31) 12. Meißen plate celebrating Saint Barbara, early twentieth century (32) 13. Eduard Heuchler, plate from Die Bergknappen in ihren Berufs- und Familienleben, 1857 (34) 14. View of the Kirunavaara mine, Kiruna, Sweden, ca. 1905 (37) 15. View of the Krupp Stammhaus, constructed ca. 1818 (40) 16. John Bowen, “Stac Fawr,” smokestack at the Llanelli Copperworks, 1861 (41) 17. Aerial view of the original Tata steel plant, Sakchi, ca. 1907 (42) 18. Site plan of the Gewerkschaft Deutscher Kaiser, Duisburg, 1912 (44) 19. American Expeditionary Forces, “Panorama of Krupp’s Works, Essen,” ca. 1918 (45) 20. Krupp photomicrographic study in Untersuchungsberichte, June 1929 (48) 21. Female workers on break, Essen, ca. 1914–18 (50) 22. Crucible carriers at Krupp steelworks, from Krupp Eisen und Stahl, Essen: Schutzvorrichtungen, ca. 1903 (51) 23. Crucible carriers at Krupp steelworks, from Krupp Eisen und Stahl, Essen: Schutzvorrichtungen, ca. 1903 (51) 24. Postcard view depicting the Villa Hügel, Essen, ca. 1912 (54)

25. Rainer Metzendorf, “Gartenvorstadt Margarethenhöhe,” 1919 (59) 26. View of Homestead, Pennsylvania, ca. 1910 (60) 27. View of workers’ housing on Avenue Saint-Sauveur, Le Creusot, 1912 (62) 28. View of Creswell Model Village (project completed 1895) (63) 29. View of the Via Krupp, Capri, 2020 (64) 30. Diagram of the steam engine locomotive and its energy needs in coal over time, 1935 (66) 31. Postcard view of the Krupp foundries at Essen (68) 32. Plate from the International Smoke Abatement Exhibition catalog, 1881 (71) 33. Maximilien Ringelmann, Ringelmann smoke charts, ca. 1888 (72) 34. Jules Tavernier and Paul Frénseny, The Manufacture of Iron—Carting Away the Scoriae, 1873 (73) 35. Plate from Arthur Guttmann, Die Verwendung der Hochofenschlacke im Baugewerbe, depicting the microscopic formation of slag variants, 1919 (76) 36. Plate from Arthur Guttmann, Die Verwendung der Hochofenschlacke im Baugewerbe, depicting the characteristics of slag-based mortars, 1919 (77) 37. Plate from Arthur Guttmann, Die Verwendung der Hochofenschlacke im Baugewerbe, depicting worker housing layouts, 1919 (78) 38. Plate from Arthur Guttmann, Die Verwendung der Hochofenschlacke im Baugewerbe, depicting the Berlin-Stettin canal overpass, 1919 (79) 39. Plate from Arthur Guttmann, Die Verwendung der Hochofenschlacke im Baugewerbe, depicting the laying of slag tar in the Ruhr Valley, 1919 (79) 40. Henry Taunt, Workmen with a Steamroller in High Street, Oxford, Oxfordshire, ca. 1891 (80) 41. Slag dump with glowing cinder, 1932 (81) 42. Diagram showing changes to the world’s surface vegetation (84) 43. Caspar David Friedrich, Der Chasseur im Walde, 1814 (87) 44. Henry Bessemer, portion of original patent drawing for the Bessemer converter, 1855 (90) 45. Plate from Arthur W. Brearley and Harry Brearley, Ingots and Ingot Moulds, depicting crystal formation in a Krupp ingot, 1918 (92) 46. Leonardo da Vinci, sketch of a rolling mill, ca. 1500–1510 (94)

47. Alfred Krupp, sketch depicting two workers with hammers, ca. 1835 (95) 48. Adolph Menzel, The Iron Rolling Mill (Modern Cyclopes), ca. 1872–75 (96) 49. View of test pieces for the Weichselbrücke, Dirschau, produced by the Gutehoffnungshütte of Oberhausen, ca. 1888 (100) 50. Page from the sales catalog of the International Steel & Iron Company, ca. 1919 (102) 51. Illustration from Josef Durum, Hermann Ende, Eduard Schmitt, and Heinrich Wagner, eds. Handbuch der Architektur unter Mitwirkung von Fachgenossen, 139. (106) 52. View of the Krupp pavilion at the World’s Columbian Exposition, 1893 (111) 53. Krupp’s display at the 1902 Düsseldorf fair (114) 54. Bruno Taut, Glass Pavilion, Deutscher Werkbund Exhibition, 1914 (115) 55. Map of the Rhine watershed and its major iron and steel factories around 1870 (118) 56. View of the Dombrücke, Cologne, ca. 1870 (119) 57. E. Martin and E. Chevaillier, isochronic map, 1882 (120) 58. Albrecht Penck, isochronic map, 1887 (121) 59. H. & C. Graham Ltd., The Prussian Octopus, ca. 1915 (123) 60. G. F. Sargent, Iron Bathing Kiosk for the Viceroy of Egypt, 1860 (128) 61. Illustration of a steel church by Forges d’Aiseau, 1889 (129) 62. Eugène Freyssinet, airship hangar at Orly Airport, ca. 1924 (132) 63. Interior view of the Festhalle Frankfurt, 1951 (134) 64. Postcard view of a destroyed building from the Brussels Exposition Universelle, 1910 (134) 65. View of Max Berg’s Centennial Hall, Wrocław, completed 1913 (136)

viii

Illustrations

66. Max Berg, sketches for the design of the Centennial Hall, Wrocław, ca. 1911 (136) 67. Interior view of Gottfried Semper’s Semperdepot, Vienna, completed 1877 (141) 68. Illustration of steel column capital designs from the Berlin transit network, 1882–1913 (142) 69. Construction of the Spreetunnel, 1913 (145) 70. Constantin P. Pappa, Arif Paşa Apartmanı, Istanbul, completed ca. 1903–6 (147) 71. Constantin P. Pappa, detail of structural system in the Arif Paşa Apartmanı (149) 72. View of the first stainless steel conveyor belt, 1901 (158) 73. Oscar Graubner, Margaret Bourke-White atop the Chrysler Building, ca. 1930 (159) 74. Aerial view of Passchendaele before and after battle, 1917 (161) 75. Auguste Hippolyte Collard, Ossature du Pont St.Louis, 1861 (164) 76. Images from Jules Andrieu, Désastres de la guerre (165) 77. Ruins of the Palace of St. Cloud, Saint-Cloud, France, 1870 (166) 78. Steel frame of Ruef Building, destroyed Aronson Building, destroyed Mills Building, and intact “painted ladies” after the San Francisco earthquake of 1906 (168) 79. Detail of the Krupp cast-steel factory at Essen showing scrapyard, 1897 (172) 80. View of ruins from the fire of 1916, Bergen, Norway (174) 81. Albert Renger-Patzsch, Ein Knotenpunkt der Fachwerkbrücke Duisburg-Hochfeld, 1928 (180) 82. Bernd and Hilla Becher, Winding Towers, 1967–88 (182) 83. Poster celebrating the “Day of Free Europe” and the creation of the ECSC, 1952 (184)

Acknowledgments

I first began thinking seriously about materials

copyediting. It has been an honor to work with a

in architecture school. I loved making models

publisher so committed to art-historical scholar-

and pushing the limits of how that could be done

ship and such finely produced books.

and with what. I fondly remember stalking the

display cases of my campus store, caressing balsa

the form of time and money from a number of

and basswood, foamcore, plexi, concrete, resin,

institutions, including a Summer Stipend Award

styrene, chipboard, clay, piano wire, and much

and Fellowship from the National Endowment for

more to conjure inspiration for how I wanted to

the Humanities, a research leave with the Forum

make my next creation. This world of architecture

Transregionale Studien in Berlin, the Richard

in miniature was liberating because, for the most

Rogers Fellowship in London from the Harvard

part, I could afford the material parts and was in

Graduate School of Design, a research fellowship

control of how they came together. With time, and

from the Gerda Henkel Stiftung, a publication

a shift to the scholarly side of architecture, I came

grant from the Graham Foundation, and a John

to realize that what I loved about materiality was its

Simon Guggenheim Fellowship.

intrinsic truths. Unlike the issues of form or style,

materiality felt like a world of positivistic clarity:

superb and I owe them thanks for making my uni-

materials have limits and definable characteristics

versity life so enriching. My students are superb as

that are not open to interpretation. And they have

well, and a number of them, at both the University

an intrinsic relationship with our natural world

of Rochester and Cornell University, have taken

that discourse, despite all of its exciting dynamics,

seminars I have directed on the topic of materiality.

does not. With this book, I hope I have made good

Christian Sancto, Julia Tulke, and Mimi Cheng

on the intellectual meditations that so fascinated

deserve special mention here as stellar, probing

the young model-maker version of me more than

doctoral advisees. Kathleen James-Chakraborty,

two decades ago.

Barry Bergdoll, and Esra Akcan have been tireless

colleagues and mentors and I remain grateful for

To realize this goal, I have benefited from

I have been fortunate to receive support in

My colleagues at the University of Rochester are

the professionalism of the staff at the Penn State

their steadfast support, criticism, and collabo-

University Press, especially Ellie Goodman,

ration. Dasha Lynch, another brilliant student,

whose early and decisive interest in this project

did superb work proofing odds and ends in the

has made her an ideal collaborator. I wish also to

bibliography. Ripp Greatbatch served a vital role in

thank Maddie Caso for her administrative guid-

researching and clearing images for publication.

ance and Laura Reed-Morrisson, Jennifer Norton,

Brian Beer, and Regina Starace for their produc-

“chosen family”—who engage my work with such

tion expertise. Suzanne Wolk provided expert

interest and who also inspire me to engage things

I am lucky to have friends—an extended

besides my work. For this I thank Nick Adderley,

Llerena Searle, Jenny Sedlis, Laura Smoller, Flavio

Kliment Alexiev, Tanya Bakhmetyeva, Natasha

Trevisan, Graeme Vaughn, and Stewart Weaver.

Case, Sam Chermayeff, Theo Clinkard, Edward

Elles, Freya Estrellar, Jeremy Faro, Peter Hermann,

Hewitt and Dale Christensen, for everything they

Ben Homrighausen, Marguerite Humeau, Maureen

have done for me. Finally, I thank Ripp for his

Jeram, Christian Larsen, Casey Miller, Reinhard

quiet support and remarkable centeredness, which

Ostendorf, Miriam Peterson, Michael Pilato,

has kept me moored in tumultuous times; he is an

Alexander Pohnert, Nathan Rich, Eyal Rozmarin,

old soul who brings new life.

Note on Translation and Format Throughout this manuscript, places are referred to by their relevant historical place-names (e.g., Breslau, not Wrocław), with the exception of cities of publication in the bibliography, where I use the modern anglicized place-names (e.g., Munich, not München), when they exist. All translations from German, modern Turkish, and French are my own.

x

Acknowledgments

I remain in the debt of my parents, Patricia

besides my work. For this I thank Nick Adderley,

Llerena Searle, Jenny Sedlis, Laura Smoller, Flavio

Kliment Alexiev, Tanya Bakhmetyeva, Natasha

Trevisan, Graeme Vaughn, and Stewart Weaver.

Case, Sam Chermayeff, Theo Clinkard, Edward

Elles, Freya Estrellar, Jeremy Faro, Peter Hermann,

Hewitt and Dale Christensen, for everything they

Ben Homrighausen, Marguerite Humeau, Maureen

have done for me. Finally, I thank Ripp for his

Jeram, Christian Larsen, Casey Miller, Reinhard

quiet support and remarkable centeredness, which

Ostendorf, Miriam Peterson, Michael Pilato,

has kept me moored in tumultuous times; he is an

Alexander Pohnert, Nathan Rich, Eyal Rozmarin,

old soul who brings new life.

Note on Translation and Format Throughout this manuscript, places are referred to by their relevant historical place-names (e.g., Breslau, not Wrocław), with the exception of cities of publication in the bibliography, where I use the modern anglicized place-names (e.g., Munich, not München), when they exist. All translations from German, modern Turkish, and French are my own.

x

Acknowledgments

I remain in the debt of my parents, Patricia

Introduction

Let us not, however, flatter ourselves overmuch on

they need: food, clothing, shelter. We don’t need

account of our human conquest over nature. For

single-use plastics or a brand-new wardrobe every

each such conquest takes its revenge on us.

season or vacations halfway around the globe. We

—Friedrich Engels, Dialectics of Nature, 291–92

must unlearn the wantonness of the consumer culture that is force-fed to us by the marketeers of

Enough is enough. This is a mantra of the “enough

late capitalism. Just as responsible people do not

movement,” a movement of largely Western citi-

spend more money than they earn, so too should

zens concerned about the rapid degradation of the

we resist the temptation to place a burden on the

earth caused by the wrath of unending growth and

global commons that is greater than what it can

industrialization, manifesting itself in the existen-

handle. Enough is enough.

tial crisis of our time: the “wicked universality”

of climate change. The enough movement argues

cal turn to questions of sufficiency and consumer

that unmitigated economic growth, assumed to be

culture originates is not humanism but science.

a basic and justified goal of every nation and every

As Dipesh Chakrabarty argues in his landmark

individual on earth since at least the advent of the

essay “The Climate of History: Four Theses,” the

1

The bedrock on which this urgent philosophi-

Industrial Revolution, is patently unsustainable.

Anthropocene, the period in which human agency

Perhaps to the detriment of a focus on the sys-

became powerful enough to disrupt geology, is

temic and strategic political issues of regulation,

an unequivocal reality that in turn disrupts the

the movement focuses on the tactical consumer

continuity of human experience.3 In other words,

choices of individuals. A majority of those indi-

a disruption of geology is a disruption in the

viduals in the West already have every basic thing

human experience, which in effect necessitates

2

a disruption in thinking. Even if the cynic wipes

gluttonous, more than enough. We do not need

away pop movements like the enough movement

indoor skiing centers in the desert. We do need

and buzzy lingo like “Anthropocene” and “dis-

to house the homeless. Beauty in architectural

ruption,” what remains is a cold, hard reality that

form is a worthy pursuit. Excess is not. What is the

can be ignored only by a very real and new cult of

difference?

post-truthism. The quest of the “enough” move-

ment, despite its fixation on the consumer instead

tackle this question wholeheartedly, and there are

of the regulator, holds important tenets that may

some logical reasons why this might be the case.

help us leverage Chakrabarty’s theses from the out-

The most obvious is that the climate crisis—and

side in. The philosophical pursuit of enough—of

our adaptation to it—is something that is unfold-

sufficiency—has in it the capacity to transcend the

ing today and into our future and that history can

-isms that might otherwise preoccupy the fore-

imperil its own autonomy and intrinsic value when

ground of a scholarly consideration of the modern

it subordinates itself to instrumental purposes, such

period: neoliberalism, progressivism, Marxism.

as explaining a path to current events. The contem-

Capitalism and its limits, in this context, are a

porary and prospective condition, after all, would

matter not of ideology but rather of the survival of

seem to be the domain of designers. We can simply

flora and animal species, including Homo sapiens.

analyze their decisions in twenty or more years’

Histories of imperialism, colonization, and global-

time and make sense of them with the safe dis-

ization and the methodological focus of feminism,

tance that time provides. This position, which until

poststructuralism, and decolonization all take on

recently seemed so admirable for its disinterested-

new valences when framed as a matter not only

ness, feels increasingly untenable and neglectful.

of the value of the human but also of her survival.

Do we even have twenty years to wait? What can

Whether framed as an intersection or a dialectic

we contribute now, rather than later? How can the

of science and humanism, we can reject this reality

discipline of history address our ecological crisis

only if we believe that the two pillars of human

and offer our colleagues in design and other fields

knowledge—science and humanism—are mutu-

synthetic ideas that are rooted in history and resist

ally exclusive. Chakrabarty poignantly reminds

the facile cliché of history repeating itself or the

us that the “mansion of modern freedoms stands

need to learn some sort of inevitable lesson?

on an ever-expanding base of fossil fuel use.” An

architectural historian will not—and should not—

forward. The first is to displace the human from

resist the temptation to see something specific in

the center of architectural history, a displacement

Chakrabarty’s allegorical mansion.

that may be an ethical imperative in light of the

trouble humans have wrought on the earth by

4

2

Which brings us to a question. Where does

The field of architectural history has yet to

In pursuit of this task, there are two clear ways

architecture figure in this picture of a brave new

placing themselves at the center to begin with. This

world of enoughness? That question, the specula-

is not to argue that humans are unimportant or

tive force behind this book, is not an easy one to

negligible in the creation of architecture—they are

answer. Architecture can just as easily be no-non-

clearly and inarguably the core of everything that

sense shelter—enough—as it can be superfluous,

architecture is about. Yet all too often our notion of

Precious Metal

the human is framed around tropes and concepts,

contexts of these figures. By this I do not mean

such as “masterpiece,” that patently resist holistic,

their appreciation for the natural environment,

ecological narratives and promote timeless ideals

something that seems essential for any decent work

in their stead. This framing goes back more than a

of architecture, but rather how the materials and

century to the formation of architectural history as

processes they employ interface with the materials

a discipline, and to its largely uncritical adoption

and processes of nature itself—in other words, the

of the conventions of art history and the words that

roles of these multiple authors as designers not

are used to describe the solitary pursuits of media

merely of form but of ecological relationships.

like painting and sculpture.

materiality. This seems to be a logical next step in

5

Take the concept of genius, for example, an

The second way forward is to emphasize

adjective and noun that has been used to describe

thinking about the built environment after displac-

countless architects of the past and the present.

ing the human from the center, as it surreptitiously

“Genius,” as a word, has a long history involving

brings us back to what Bruno Latour calls the

two etymological origins and several distinct

“terrestrial,” in which one occupies a territory that

meanings. Nevertheless, the word has carried

is bound to earth, the power of which derives from

with it an air of being utterly self-evident in the

what can be sustained there.7 The ecologist and

modern period, requiring close to no qualitative

indigenous theorist Robin Wall Kimmerer provides

or quantitative explanation. As Ann Jefferson

a useful new template with which to think like a

notes, the word “genius” acts as “an accolade that

scientist, as the climate crisis demands, while also

defines its object as an exception in a class of its

thinking about the spiritual value of deanthropo-

own . . . possessing rather more evaluative purpose

centrizing our knowledge systems, as humanism,

than precise semantic content. . . . If one pauses to

ironically, demands. She explains this through the

reflect, however, ‘genius’ is oddly hard to define,

act of weaving baskets with sweetgrass:

and what is odder still, this does not seem to count against its viability as a concept. Speakers continue

In weaving well-being for land and people, we need

to use the word as if they can count on listeners to

to pay attention to the lessons of the three rows [of

understand what they mean, and the attribution of

basketmaking]. Ecological well-being and the laws of

genius is often used as a clincher in discussions as

nature are always the first row. Without them, there is no

if to suggest that the word is entirely self-justify-

basket of plenty. Only if that first circle is in place can we

ing.”6 This is precisely the case in the monographic

weave the second. The second reveals material welfare,

strain of architectural history, which has reified

the subsistence of human needs. Economy built upon

Wright, Mies, and Le Corbusier, among others,

ecology. But with only two rows in place, the basket is

without sufficiently pausing to fully probe the

still in jeopardy of pulling apart. It’s only when the third

innumerable other people—architects, engineers,

row comes that the first two can hold together. By using

builders, and users—who are, unlike in the case

materials as if they were a gift, and returning that gift

of painting or sculpture, necessarily involved in a

through worthy use, we find balance. I think that third

work of architecture. Nor does this strain of archi-

row goes by many names: Respect. Reciprocity. All our

tectural history fully wrestle with the ecological

Relations.8

Introduction

3

4

What if steel (or glass, or any other material)

new, not in the spoils of or references to the past.

is rethought as a gift from the earth, not some

Indeed, architectural modernism has often touted

endless resource? How valuable is that gift when

its material innovations as ex nihilo.

we consider what sacrifices and labor have gone

into it? How do we accept that gift with humility?

earth is not incidental. “The very notion of soil

And how do we find “worthy use” of that gift and

is changing,” says Latour, directly addressing the

return our gratitude to the source from which

semantic shift of the word “soil” in the framework

it came? The architecture of the modern period,

of climate change. “The soil of globalization’s

like a brilliant new basket with brand-new tech-

dreams is beginning to slip away,” he notes. “Now

niques, was conceived afresh largely based on

if there is no planet, no earth, no soil, no territory

the invention of new materials and the enhanced

to house the Globe of globalization toward which

performance of old ones. But we have not treated

all these countries claim to be headed, then there

it like a gift; we have made it a workhorse. What’s

is no longer an assured ‘homeland,’ as it were, for

more, the importance of materiality in the making

anyone.”9 Such is the predicament of the twen-

of architecture in the modern period has been sub-

ty-first century, argues Latour, the first century in

sumed under the more fashionable rubrics of form,

which we will become fully aware of the long-term

function, and cultural meaning, divorcing it from

climatic effects of what is now called the Anthro-

ecology. What of the inherent value of materiality

pocene, not only exerting pressure on our planet

in the study of architecture, which can, in addition

but setting into motion mass migrations that have

to the ecological, also relate architecture to broader

already begun to overhaul the rules of politics on

social and political implications? This book follows

a global scale. The destabilization of soil, the con-

both of these paths—decentering the human and

temporary loss of the sacred concept of terra firma,

emphasizing materiality—as concurrent ways for-

is not tangential to the history of architecture. The

ward, interweaving and interrelating them at every

very heavy industrial processes that brought us

possible juncture.

plate glass, iron, steel, and plastic are among the

many anthropogenic achievements that have also

The questions of ethics that run through any

That this book both begins and ends in the

study of the built environment and its relation-

turned up temperatures and raised the level of the

ship to human ecology are enormous. This book

sea. Globalization, fueled as it is by carbon emis-

attempts to make them more manageable by

sions, has been transformed from a cosmopolitan

focusing on two materials, iron and steel, and it

idea into one that is frighteningly provincial and

goes yet further by circumscribing the investi-

small-minded.10 The result is a self-aggrandizing

gation within certain sensible contours of both

narrative of progress that also advocates a kind of

geography and chronology. Those contours center

apolitical, anti-ecological framework, one in which

on the time and place where modernism began its

modern architecture exists both apart from history

radical break with history, the industrial West in

and outside the natural world in which things,

the long nineteenth century. This was an era that

including buildings, are born, die, and return to

saw the gradual dissolution of dynasties and the

the earth. Needless to say, modernism does not

rise of the nation-state, whose greatness lay in the

exist outside history or ecology, and one of the

Precious Metal

main goals of this book is to introduce ways to read modernism from the bottom up, so to speak.

It is worth noting that the term “ecology,” the

spatial and temporal patterns of the distribution, abundance, and interrelationship of organisms with nature and one another, was indeed coined in Germany in the period this book focuses on, by Ernst Haeckel in his book Generelle Morphologie der Organismen, published in 1866. Although the roots of ecological thinking go back at least to the ancients, it was in the nineteenth century, through the collective work of Haeckel, Alexander von

Figure 1. King Tutankhamun’s meteoric iron dagger, ca.

Humboldt, Isaac Newton, Eugenius Warming, Carl

fourteenth century BC. Photo courtesy Sandro Vannini /

Linnaeus, and Charles Darwin, foremost among

laboratoriorosso.

others, that ecology emerged as a credible way of discussing life on earth. With that credibility began the tabulation of the human habitat’s growing

from iron ore, and they remain chemically similar,

imbalance in nature. If the era of the Anthropocene

with minor differences in their proportions of iron,

was hatched in the age of discovery, it was in the

carbon, silicon, sulfur, phosphorus, and manga-

nineteenth century that it gained self-awareness.

nese that make for significant differences in their

This self-awareness came at a time that could

structural carrying capacity. Following centuries

not have been more inconvenient: industry was

of sporadic and unsystematic smelting elsewhere,

booming and cities were growing horizontally and

iron gained a deep cultural currency in ancient

vertically with the outsized help of iron and steel.

Egypt. At some point during his short reign (ca.

The capacity for critical inquiry into the inability

1334–1325 BC), Tutankhamun, popularly known as

of human ecology to coexist with modernity and

King Tut, acquired a dagger whose blade was later

modernism was always stunted because capitalism

discovered to be made of iron hammered from a

accelerated the dissymmetry.

meteorite (fig. 1).12 The dagger is one of a handful of

precious objects made of meteorite iron that signal

Of all the heroic building materials of mod-

ernism, steel and iron are perhaps the ripest for

the material’s extremely rare—and valuable—

this effort. Steel and iron, the most ubiquitous of

status, as iron from outer space has a higher nickel

humankind’s advanced metals, are the culmina-

content than earthly iron. These objects therefore

tion of a succession of metals that are often used

indicate that humans’ initial contact with the metal

to measure humans’ civilizational sophistication

occurred when it was serendipitously found on the

over time and, in two cases—bronze and iron—

earth’s surface. King Tut’s dagger is a symbol of the

to periodize three millennia of human and, by

end of a chronological period when metals, found

extension, archaeological history. To understand

easily on or near the ground, served as décor for

steel, we must first understand iron. Both derive

the everyday modification of humans’ bodies and

11

Introduction

5

their environment.13 In the period that followed,

to T. J. Demos and numerous others, justifies

humankind would turn its focus to that which was

identifying this point as the beginning of the

not readily apparent on the earth’s surface but lay

Anthropocene.17

beneath it, and society would be fundamentally

changed by the structural use of these metals.

edge that coursed through the age of discovery and

ultimately the Enlightenment put an abrupt end to

The ferrous metallurgy of terrestrial iron

ore, requiring a sustained melting point of 2,800

several misconceptions about the planet, such as

degrees Fahrenheit, necessitated kilns and hearths,

the notion that it was flat, and all of this led to a far

which appeared in different places at different

more complex understanding of human ecology.

points in time and in different civilizations,

But, as the Copernican revolution demonstrated,

including the Achaemenids in the Near East, the

advances in human knowledge were not always

Greek, Roman, and Viking civilizations in Europe,

tantamount to a fuller or more ethical philosophy

and the Ashoka people of the Indian subcontinent.

of the environment. While Copernicus may have

The written records of these civilizations and their

refuted pseudosciences such as astrology and

successors indicate an increasingly common asso-

alchemy, his placement of the earth at the periph-

ciation between the material superiority associated

ery rather than the center of the universe would

with iron and moral achievement. The mining of

ultimately prepare modern subjects to resist deep

iron ore entered a feedback loop with the mining

ecology, or the idea that every living being has an

of coal, which allowed the iron ore to be heated at

inherent worth regardless of its utility to humans.18

higher temperatures and in greater amounts, and

Crazy as it may sound, for many, scientific dis-

this in turn provided for objects of greater size,

covery supplanted superstition and faith-based

utility, and strength. Steel emerged from this loop,

thinking, and justified the idea that the complex

with its superiority to cast and wrought iron, and

interrelationships between living and nonliving

its greatest first applications lay in the creation of

things on earth were not particularly unique or

weaponry. These advances, coupled with some

fragile and that anthropocentrism was in turn fully

misfortune in the immune systems of the people

justifiable.

of the “New World,” are what Jared Diamond has

famously argued tilted the rest of history’s fate in

perversion of Enlightenment science facilitated the

favor of Europe from the early modern period

imminent Industrial Revolution and the environ-

onward.15 The orientation toward the New World

mental degradation that would follow it, but at

also signaled an elementary orientation shift in

the very least it makes clear how the drive for the

global affairs away from the Mediterranean world

accumulation of capital associated with the period

to that of the Atlantic, a shift that we see reflected

could be justified in anthropocentric terms. As it

in the steel industry centuries later.16 The year 1492,

turns out, capitalism has no intrinsic implements

in which Columbus “discovered” the Americas,

for enforcing environmental accountability. Lest we

marks a massive change in the stratigraphic record,

forget, it was this drive toward wealth accumula-

demonstrably showing the impact of carbon on the

tion, so well documented by Weber, Marx, Engels,

environment for the first time—which, according

Malthus, and others, that led to the vertiginous

14

6

The rapid uptick in the production of knowl-

Precious Metal

It would be overly causal to suggest that this

detonation of inequality and the confusion today between living standards and quality of life.19 This is just one reason for the suggestion that we adopt the word “capitalocene” in place of “anthropocene” to honestly describe the situation from the nineteenth century onward.20

The earliest decades of the Industrial Revolu-

tion witnessed a rise in the availability of portable commercial goods like plows and pots made of ferrous metals, although structural wrought iron, cast iron, and steel were largely still too difficult to produce. Their potential, however, could no longer be in doubt after the completion of Thomas Far-

Figure 2. Unknown, Iron Bridge at Coalbrookdale. Photo:

nolls Pritchard and John Wilkinson’s Iron Bridge at

akg-images / De Agostini / Biblioteca Ambrosiana.

Coalbrookdale in the north of England, the world’s first major bridge to be made of cast iron, in 1781 (fig. 2).21 The Iron Bridge served as a harbinger of

one American entrepreneur, Andrew Carnegie,

Britain’s dominance in structural metals for the

to declare, “Farewell, then, Age of Iron; all hail,

century that followed.

King Steel.”24 By the final quarter of the nineteenth

century, steelmakers and some iron manufactur-

Henry Cort’s puddling process led to further

advances in the use of structural wrought iron

ers on either side of the Atlantic were producing

in the hulls of ships and bridges.22 Engineers and

wide flanged beams and other structural steel

inventors all seemed to know, though, that the

units adaptable, in concert with one another, to

future of structural metals lay in the premium

any number of recombinations in architecture and

potential of steel. That is what led Henry Bessemer

civil engineering. Certain historical events—such

to unveil the metallurgical process bearing his

as the Great Chicago Fire of 1871 and the expan-

name in 1856, a process in which air was blown

sion of railways across the American West—were

through molten pig iron to remove its impurities,

particularly fruitful for the development of

which in turn allowed for the production of very

structural steel in that they furnished tabula-rasa

high-quality steel that was easier, quicker, and

opportunities to conceive and create radically new

seven times less expensive to produce than was

building typologies, such as the skyscraper and the

possible with earlier methods. Bessemer’s method

open-span railway station. Structural steel became

is one of the punctuation points of the second

the measuring stick by which all other materials

Industrial Revolution and laid the groundwork for

were judged, and was in fact the wellspring of its

early steelworks such as Sir John Fowler and Benja-

own greatest competitor in the twentieth century:

min Baker’s Forth Bridge, completed in 1890.

reinforced concrete.

23

The open-hearth, puddling, and rolling pro-

cesses all advanced at breakneck speed, which led

But at what cost? The economic success of

many companies, including those in the steel and

Introduction

7

by the exploitation of fossil fuels (fig. 3). This book, as part of its attempt to force a reckoning in the field, offers some less obvious but equally important images of the slow impact that architecture has concomitantly played in altering our climate.

This book does not seek to condemn iron or

steel. To be clear, these metals have had a radical impact on architecture, forever changing how we perceive and inhabit buildings: they liberated the floor plan from columns, allowed the pursuit of the cantilever, and provided the ability to hang façades as if they were curtains. This we already know, and these are things we should all admire. What isn’t discussed, however, is that these metals Figure 3. Aerial view of oil on the surface of the sea during

also produced a radical new ecology that reflected

the Deepwater Horizon oil spill, coast of Louisiana, Gulf of

a changed (although not depristinated) relation-

Mexico, August 2010. Photo: Nature Picture Library / Alamy

ship between humans and the environment, not

Stock Photo.

to mention between disparate cultures. These two ecologies, natural and intercultural, constitute the

8

construction industries, was measured by their

two lenses of the proverbial glasses through which

ability to meet investor expectations over absurdly

this book was researched and written, and they

long periods of time, some as much as a century.

color every object and theoretical concern it raises.

This enshrined the necessity, barring the pro-

These lenses will necessarily show the damage

duction of any comparable energy alternative, of

wrought by steel production while also highlight-

burning fossil fuels to meet long-term financial

ing the occasional moments when it has acted with

expectations. The commonalities between today’s

particular efficiency and suggested untapped eco-

climate crisis and colonialism, which began in

logical potential. This book jettisons iron and steel’s

earnest in the period this book addresses, are

familiar guise as the heroic aid to the “genius”

increasingly clear: both meant dispossession, the

architects and “masterpieces” of modernism;

former of territory, the latter of sovereignty.

instead, the ordering logic of this book considers

The difficulties associated with making images

steel’s ecology as distinct in time, coming from the

of the slow, gradual process of climate change has

earth, passing through human hands, and eventu-

also stymied a more robust response over the past

ally returning, in some way, back to the earth.

few decades. It is only recently that we have finally

begun to see and highlight those images. The

logical circumscription of the book and what

Deepwater Horizon oil spill of 2010, for example,

enables a “horizontal” approach also to proffer

put a painful, if necessary, image into circulation,

“vertical” depth, something that histories rooted

one that showed the unmitigated damage caused

in primary sources ought to do. The book’s

Precious Metal

This brings us to the geographical and chrono-

documentary center of gravity features Krupp, the

economy.26 This microcosm of German power has

global titan of the German steel industry during

attracted a fair share of scholarship, particularly

the second Industrial Revolution. For about a for-

Marxist interpretations, but the Marxist framework

ty-year period leading up to World War I, Krupp

has also limited the scholarly cone of vision to the

exemplified the stratospheric rise of German might

analogic dyad of corporation and nation. This book

that followed the consolidation of the German

moves beyond this dyad and the fields of economic

Empire in 1871. Prior to this, Germany was well

and political history by exploring the role of steel

behind England, and afterward it would be eclipsed

in a global context through the lenses of architec-

by the United States. The story of German steel can

tural and environmental history, two fields that are

thus serve as a primer on the nature of industrial

absent in the scholarship. Further, to limit the story

power as it transitioned from the world of empires

to Krupp, as important as the company may have

to the world of nations: Krupp is an entity that

been, would be to ignore too many other pivotal

emerged from a regional culture centered on crafts

companies and production sites that promote, in

and interregional trade to become an industrial

much the same way that the genre of biography

and military powerhouse with immense political

can, a kind of hagiographic narrative that works

capital on the global stage. However, broad-minded

against the ecological situatedness of this book.

historical studies of the nineteenth century have

tended to gloss over Germany, relying on the rather

Germany as the Gründerboom and globally as

simplistic aphorism that the eighteenth century

the “age of steel,” is strategic not only because it

belonged to France, the nineteenth to England, and

isolates the singular importance of Germany’s role

the twentieth to the United States (with specu-

in shaping the ecology of steel both nationally and

lation that the twenty-first will belong to China,

internationally, but also because it highlights a set

in no small part the result of its booming steel

of discrete historical conditions that can easily be

industry).

overshadowed by the sheer scale of twentieth-cen-

tury wars and markets.27 The most important of

25

Yet this book also has a decidedly global

This roughly forty-year period, known in

and international scope, as it not only examines

these historical conditions is the ambiguity of the

the macro implications of the steel industry in

environmental impact of mass industrialization.

Germany but also interweaves that analysis with

During this period, in which the Romantic move-

a considerable amount of substantive compara-

ment in art and literature that prized nature so

tive material from France, the Ottoman empire,

highly began to fade, there was an understanding

the Indian subcontinent, the Austro-Hungarian

that the soot and pollution of the steel and other

Empire, England, the United States, and elsewhere.

industries were at least fleetingly problematic for

As with Bethlehem Steel and later Ford in the

the quality of life on earth. However, a bona fide

United States, Peugeot in France, and Mitsubishi in

environmentalist movement, including the con-

Japan, the confluence of corporate, industrial, and

cept of a carbon footprint, was yet to materialize.

national history found at the Krupp headquarters

This made for a moment in which confidence in

in the Ruhr Valley is stunning in how it marks the

industry and technology prevailed over a stir-

corporation as a microcosm of the nation and its

ring insecurity about the mortgage that mankind

Introduction

9

10

Suraiya Faroqhi and Zülal Kılıç’s Osmanlı

was placing on the future. This moment may be

instructive as the second great wave of techno-op-

Zanaatkarları is an important work on Ottoman

timism recedes in the twenty-first century and we

craftsmen that examines how individual guilds

encounter a new wave of hope that technology can

developed largely around concepts of expertise as

reverse the very problems we let it create in the

they related to specific materials, in turn shaping,

first place—which raises the question: which leaps

among other things, the organization of labor

of faith merit our collective investment and which

in the sphere of construction. Suzanne Preston

do not?

Blier and James Morris’s work on adobe archi-

tecture in West Africa, Elisabetta Conti’s edited

As a revisionist interpretation of the history

of metals that combines the methods of environ-

volume on steel in Italy, Hamady Bocoum’s study

mental history with business and trade history

of Africa’s metallurgical history, and Mario Rinke

collected from various archives, this book nec-

and Joseph Schwartz’s edited volume on wood all

essarily engages a wide body of primary and

provide superb models of material-centered stud-

secondary literature. Stuff Matters: Exploring the

ies whose methodologies and gleanings offer the

Marvelous Materials That Shape Our Man-Made

most sophisticated and up-to-date approaches in

World, by Mark Miodownik, brings a material

this small and emergent methodological subfield

scientist’s lens to the study of steel and ten other

to date.

common materials. Although Precious Metal

adopts some similar strategies, it extends the depth

book, be they corporate or individual, none enjoys

of Miodownik’s approach by focusing on a specific

a more developed body of literature than Krupp,

material. Sigfried Giedion’s Bauen in Frankreich,

with particularly strong works in political and

Eisen, Eisenbeton is an important early example of

economic history. Harold James’s Krupp: A History

material-focused architectural history that exam-

of the Legendary German Firm is the most recent

ines a composite material also discussed in this

comprehensive biography of the firm over many

book: reinforced concrete. Precious Metal draws

generations, synthesizing a vast body of scholar-

on Giedion’s historiographic legacy but goes one

ship and augmenting it with some new archival

step further by inscribing it within the concerns of

research.

deep ecology. Adrian Forty’s Concrete and Cul-

ture: A Material History is another material study,

representing a distinct phase in the life cycle of

influential in focusing not on a material’s techni-

steel. The first chapter, “Origin,” explores the birth

cal properties but rather on its effects on culture

of steel in architecture by examining the mining of

across time and space. Tony Fry and Anne-Marie

coal and iron ore for steel production, the geolog-

Willis’s Steel: A Design, Cultural, and Ecological

ical and metallurgical research behind iron and

History addresses steel’s role in industrial design

steel, and the processes of environmental degra-

and mechanics. While both Concrete and Culture

dation and displacement this entailed. Mining is a

and Steel are comprehensive, neither addresses the

robust subfield of environmental history,28 and this

environmental aspects at the center of Precious

chapter brings the concerns of that field to bear

Metal.

on architecture by examining how prospecting

Precious Metal

Of all the actors that shape the narrative of this

This book is divided into six chapters, each

developed and how the earth came to be under-

parts that manufacturers imagined and engi-

stood as a site of immense financial opportunity,

neered to allow for enormously complex building

despite considerable engineering challenges. The

systems, while also taking into account the impli-

chapter looks at sites in the industrial West—

cations of these open-ended construction systems

Nevada, northern England, and, of course, the

and their popularity for both the origin site and

Ruhr Valley—along with sites that the steelmaking

the building site.

powers sought to exploit in Spain, Algeria, and

Anatolia.

on how the architectural iron and steel industry

took its show on the road and internationalized

The second chapter, “Industry,” turns to cor-

The fourth chapter, “Dissemination,” focuses

porate headquarters and examines the cultural

itself economically through cultural venues,

dynamics of local labor forces. For example, Krupp

representing steel to audiences at expositions and

was one of the first companies to attract migrant

trade fairs. Two very prominent examples include

workers from across Europe, and it housed them

the 1851 Crystal Palace Exhibition in London and

in carefully designed homes and planned commu-

the 1893 World’s Columbian Exposition in Chi-

nities. This chapter examines factories along with

cago. In these exhibitions and in smaller regional

the company’s architectural and urban visions in

ones, steelmakers went to great lengths to pro-

settlements like the one at the Margarethenhöhe, in

duce impressive exhibits showing that they were

which a stylistic emphasis was placed on a German

culturally transposable. These exhibitions thus offer

Heimat instead of on international industrial

vivid glimpses into how a corporation positioned

culture. These largely nostalgic environments, built

itself as a producer of goods with global cultural

from traditional materials and in traditional styles,

value. This chapter also examines a number of

also belied the progressive nature of steel as a prod-

important, internationally circulated publications

uct, and this chapter pays special attention to the

that supported the sale and design of iron and steel

array of actors who negotiated the tension between

building parts.

old and new and looks at how companies at the

forefront of the production of modern architecture

for and dispersal of architectural steel as these

sublimated much of its technologically progressive

markets gradually became international, aided

ethos in their own building projects.

by the expansion of transportation systems and

global shipping routes. This chapter examines

The third chapter, “Production,” examines

The fifth chapter, “Building,” traces the markets

the array of iron- and steelmaking processes that

the rise of systems design and its relationship to

evolved at Krupp and elsewhere, paying particular

structural metals and the training practices of

attention to the methods and systems used in the

prominent schools of architecture like the École

production of structural units such as the I-beam,

des Beaux-Arts in Paris. It also explores the role of

as well as base trims, girts, angles, channels, rigid

iron and steel in the success of bold new projects in

frame systems, secondary framing systems, sheet-

reinforced concrete, such as Max Berg’s Jahrhun-

ing, and panels, and the machinery, equipment,

derthalle, and in the development of infrastructure

and labor necessary to support them. The chapter

in ventures like Berlin’s U-Bahn. And it looks at

also explores the increasingly diverse inventory of

how structural metals found their way abroad

Introduction

11

into open-source design systems like the Arif Paşa

Apartments in Istanbul, the Ottoman empire’s first

our built environment matters more than ever. The

building with a structural metal frame.

focus of this book—Germany’s globally situated

role in the making of the “steel age”—is intended to

The final chapter, “Return,” examines the rise

of the scrapyard and the origins of structural steel

demonstrate the importance of “horizontal” history

recycling in the nineteenth century. Although steel

for creating a more ecologically aware history of

buildings seldom came down during this period,

architecture. The book’s subtitle, “German Steel,

a handful did, and, more commonly, nonessential

Modernity, and Ecology,” reminds us that the brave

steel parts were often scrapped when buildings

new built world that modern men and women have

were updated. This chapter brings the volume full

imagined would not have been possible without

circle, returning to metallurgical science to exam-

incurring a tremendous debt to the natural world.

ine how a new recycling system that mixed scrap

This book is the ledger of that debt.

steel with iron and oxygen and burned off carbon for purification, along with the advancement of alloy technology, facilitated an entire ecology for the steel industry.

12

In a time of imperatives to think ecologically,

Precious Metal

Chapter 1

Origin

Earth

not merely the occasional deposits sitting close to the earth’s surface that were utilized in premod-

The pursuit of an ever stronger metal has always

ern times. Advances in geological science and its

begun in the earth. Whether jutting just above the

instruments made it possible to know what lay

surface or embedded deeper in the lithosphere, the

ever deeper beneath one’s feet, be it useless silt or

materialization of metals began with a look down-

profitable iron ore. Mapping pioneers like Nicolas

ward when humans first began smelting copper

Desmarest, William Maclure, and William Smith

seven thousand years ago. As the metallurgical

brought this knowledge into even greater relief,

ambitions of humans became more sophisti-

visually illustrating horizontal seams, stratigraphic

cated, so did the means by which they located the

layers, and overall patterns that, by the turn of the

reserves of ore needed to fulfill these ambitions.

nineteenth century, made it clear where the world’s

The rapidly increasing sophistication of mining

most productive large-scale mining zones would

technology—and mining productivity—that

be, with maps that could in turn chart many of the

characterizes the modern period is intertwined

most important patterns of European and North

with the establishment of geology as a scientific

American urbanization and industrialization.3

discipline in the eighteenth century and the process

known as prospecting, the act of exploring and

tography in 1815 with a map titled “A Delineation of

charting an area’s mineral deposits.2 The human

the Strata of England and Wales with Part of Scot-

appetite for strong metals that could form and

land,” which he produced after years of traveling

bear massive loads necessitated the identification

across the United Kingdom as a mineral surveyor

of large, continuous seams of coal and iron ore,

(fig. 4).4 In this hand-colored map, Smith delimits

1

Smith, in particular, pioneered geological car-

the twenty-three dominant geological substrates—

in turn providing the need and often the funding

oolytes, marbles, marls, and limestones—of most

for new and expanded departments of and research

of Great Britain. The map is as important to the

projects in geology across the continent.

history of geology as the fact that two of its zones,

“iron sand or carstone” and “coalmeasures—penant

Europe, so too did its presence in the education

pacing grindstones and millstones,” were altogether

of European architects. European institutions for

new categories with an unambiguous relationship

the training of architects, beginning with Second

to the prospects of industrialization. The composi-

Empire France and the École des Beaux-Arts in

tion also includes a sectional map titled “Sketch of

Paris, instituted comprehensive courses in geology.

the succession of strata and their relative altitudes,”

While the syllabi reveal only a passing interest

which is novel not in its own right but in its desire

in geology as it related to metallurgy, they do

to place the geological layer in conversation with

demonstrate the goal of cultivating a comprehen-

topographic relief. This graphic repertoire char-

sive knowledge of rocks and minerals, including

acterized many of Smith’s subsequent maps, many

ores, and their physical characteristics and usages.8

of which also proved influential throughout both

By the 1890s, Georges Maneuvrier, an influential

England and continental Europe.

instructor in building technology at the École des

Beaux-Arts, had instituted an ambitious two-year

German geology lagged ever so slightly behind

As the discipline of geology flourished in

English and French geology around this time, but

course comprising forty lessons in physics, chemis-

it was not without its own novel contributions.

try, and geology, in that order. Maneuvrier’s lessons

Mining academies (Hochschülen für Bergbau) had

covered descriptions of geology and fossilization

trained specialists in the mechanics of mining. At

and their relationship to sedimentary, eruptive,

the Mining Academy of Freiberg, Gottlob Werner

and metamorphic rocks, particularly those found

proved particularly influential, combining field

in France. Relying heavily on the work of Smith,

findings with his (ultimately erroneous) theory

Werner, and Maclure, Maneuvrier also trained

of neptunism—which promoted the idea that

students in the making and use of geological maps

rocks such as granite were formed by the crystal-

and sections, which in turn trained them in the

lization of the waters of a primeval ocean—into

field identification of stones, minerals, and ores.

a streamlined doctrine. Also important were

the contributions of polymath Alexander von

ing, geology, and cartography in the nineteenth

Humboldt (a student of Werner’s in Freiberg) and

century were, however, most intrinsically inter-

stratigraphist Leopold von Buch. Buch’s geologi-

twined in Germany. In this milieu, no one loomed

cal map of Germany, published in 1826, is clearly

larger than the surveyor Heinrich Karl Wilhelm

indebted to Smith and proved equally influential

Berghaus, director of the geographical institute

5

6

7

The relationships among architectural train-

a decade later (fig. 5). In both the German and the English cases, geology and mining—particularly of coal and iron ore—demonstrated a perfect science-industry symbiosis, with geologists helping to promote European mining activities, and industry

14

Precious Metal

Figure 4. William Smith, geological map titled “A Delineation of the Strata of England and Wales with Part of Scotland,” 1815. Reproduction by permission of the Buffalo & Erie County Public Library, Buffalo, New York.

Figure 5. Leopold von Buch, “Geognostische Karte von Deutschland” (Geognostic Map of Germany), 1826. Piotr Krzywiec, private collection.

advanced geological research and produced the most sophisticated and up-to-date geological maps of its day. The publication generated new geological research essential to mining in its own right by

16

at Potsdam and professor of applied mathemat-

funding explorations of iron, magnesium, silica,

ics at Karl Friedrich Schinkel’s Bauakademie.9 In

and coal and publishing the results for the scientific

Potsdam, Berghaus trained, among others, August

community. Berghaus was also the Bauakademie’s

Heinrich Petermann, Germany’s most celebrated

strongest link to Humboldt, as the two regularly

cartographer in the last third of the nineteenth

corresponded and shared findings, celebrating the

century.10 Petermann, who was essential to the con-

overlap of their respective interests in the built

tinuation of the legacy of the Gotha cartographer

and natural worlds.11 In addition, Berghaus’s own

Justus Perthes, is perhaps best known as the editor

treatises on geology from his masterwork, the

and publisher of a prolific series of geographic

Physikalischer Atlas, published by Justus Perthes

periodicals ultimately known as Petermann’s geog-

between 1838 and 1848, provided the illustrations

raphische Mitteilungen, which published the most

for Humboldt’s acclaimed study Kosmos, a series of

Precious Metal

physical descriptions of the universe first formu-

implications. Gold, silver, and diamond deposits,

lated at the nearby University of Berlin that were

like those in British South Africa, could be stripped

published between 1845 and 1862.

quickly and completely, and their intrinsic value

meant that their transport, unprocessed, back to

Just as there was a strong connection between

the academic spheres of architecture and geology

the metropole could pay for itself many times over.

in Berlin, so too were geology and industry linked

But this was by and large not the case with coal

throughout greater Prussia. Humboldt regularly

and ore because of their relative ubiquity. Even the

corresponded with Alfred Krupp, the steel magnate

colonial powers with the smallest homeland foot-

in Essen, about Humboldt’s geological findings,

print—Belgium and the Netherlands—had at least

both in Germany and abroad.12 For Krupp, the

some reserves of these materials at home.

most important aspects of Humboldt’s and Ber-

ghaus’s work were the metallurgical exponents of

There are several answers to this question. One

prospecting, namely, the geological patterns and

is the benefits that overseas prospecting could

cartographic innovations that could allow Krupp to

provide for a burgeoning multinational mining

corner the domestic and international markets in

corporation like Rio Tinto, a model in which

precious geological materials: iron ore and coal, but

economic power is achieved through multinodal

also magnesium, magnetite, and silica. Moreover, it

production rather than corporate consolidation

is clear from Humboldt and Berghaus’s correspon-

and remote resource extraction.14 Another answer

dence that both men understood that they were

is political: overseas states sought the geologi-

serving industry, probably with an eye toward the

cal expertise of European and North American

ways in which private figures like Krupp and private

scientists and mining engineers, asking them to

funds could accelerate their own research agendas.

identify their potential capacity for developing

industrial capabilities such as steel mills. The

The importance of prospecting to industry

So why was overseas prospecting worthwhile?

played a role in nineteenth-century geopolitics

consequences of such “soft-power” partnerships

as well. As the geological surveys of western and

premised on consultative geological expertise—as

central Europe and North America grew ever more

with the British in Persia or the Germans in the

sophisticated throughout the nineteenth century,

Ottoman empire—were nearly always followed by

so did the desire for—and the perceived necessity

long-term industrial relationships that benefited

of—executing a thorough global inventory of coal,

both parties.15 In both cases, the geologists from

ore, and other useful industrial deposits across the

Europe and North America marshaled an expertise

planet. If only in terms of science, this compre-

that was nevertheless contingent on local labor

hensive geographic ambition was clearly indebted

and real cooperation and promoted an economic

to Humboldt. But it was also a handmaiden of

interconnectedness that is essential to understand-

colonial power, whether relatively hard, as in the

ing globalization and its deep origins in the world’s

case of Britain and France, or soft, as in the case of

thirst for iron and, later, steel.

Germany and the United States. The prospecting

of coal and ore, unlike that of gold, silver, and dia-

extraction is a well-worn trope of colonial his-

monds, portended distinctly local and long-term

toriography. The semicolonial condition and the

13

Bald-faced exploitation through resource

Origin

17

dynamics of consultative prospecting are, however,

“scraping” and open-pit mining. Even the task of

far less well understood. An instructive example of

determining what kind of geology a given location

such a relationship is crystallized in a 1915 report

had could be a bureaucratic one. Owners of large

on the geology of Upper Mesopotamia commis-

tracts of private land were not legally required to

sioned by the Ottoman empire and executed by

allow the expedition team to enter their property

German geologists and engineers. Ottoman offi-

and test their soil through boring, scraping, and

cials commissioned the report in concert with the

other methods, though they usually permitted

long-standing partnership they had formed with

this relatively simple and also potentially lucrative

German banks and engineers in the construction

practice. Like many other governments across the

of the vast majority of their railway network, a pro-

globe, the Ottoman government exercised the right

cess that had been under way for about forty-five

to test the geology of private property through

years. Connecting Baghdad with Constantinople,

a bureaucratic application process that needed

the so-called Baghdad Railway remained incom-

to pass a certain threshold of “scientific” (read

plete at the onset of World War I in 1914. The

economic) relevance. Prospectors, including those

largest incomplete section lay in Upper Mesopo-

in the Klein expedition, were astute at dangling the

tamia, where a complete survey for the remaining

prospect of mining riches before landowners. If

railway bed was still necessary. Throughout the

geological riches were in fact found, either on the

railway’s gestation, Ottoman officials and German

ground or beneath it, the landowner had the right

engineers alike had used the process of surveying

to apply for a mining permit that was renew-

the path of the tracks as a means of discovering

able every year from the Ottoman Department

unrelated things about the terrain through which

of Mines, a state office established in 1887.17 The

the railway passed, and this sparsely populated yet

landowner was allowed to offer the tender to the

naturally promising stretch was no exception. A

highest bidder, who would then move in and begin

special team of geologists, led by Fritz Klein (who

operations.18

doubled as a gem merchant), was brought in to do

the prospecting of the region.

coloring in the geological map with information.

Geologists needed to weigh the value of exploring

The geological report, produced through an

expedition conducted in the spring of 1915 and

a given site against its proximity to railway lines

titled “Report on Some Deposits in Asian Turkey,”

and capable labor. After all, what was the point of

begins with the simple move of dividing geological

digging iron ore out of the ground if it could not

findings into two distinct classes. The first class

reasonably be transported to a place where it could

included productive deposits that were identified

be refined? And how could this be done without a

or inferred to be underground, offering evidence

significant number of trainable men between the

to both the government and industry regarding

ages of twenty and fifty looking for work and at the

the potential value of undertaking a new mine. The

ready? Even when both of these criteria were met

second class included deposits that could prove

and there were entrepreneurs who wanted to pro-

productive for industrial use and that touched

duce iron—or better yet, steel—they also needed to

the earth’s surface, which could in turn facilitate

get their hands on coal, the only form of fuel truly

16

18

Prospecting was also about far more than

Precious Metal

capable of powering this kind of heavy industry.

effects of mine subsidence, or the sinking and

If the coal was too far away, it would prove too

cracking effect of land above a mine, which could

expensive to transport. In the case of Upper Mes-

be made exponentially worse if the mine were to

opotamia, everything was in place but the railway,

collapse. At best, mine subsidence generated small

which everyone hoped was coming soon. Klein’s

sinkholes in open fields. At worst, and this was

expedition, tellingly, focused not on producing a

increasingly common in densely developed areas,

thorough geological map of all of Upper Meso-

mine subsidence ruined buildings by slowly tearing

potamia but rather on spot prospecting the areas

at them or, on rare occasions, swallowing them

around small cities and large towns through or

entirely into the ground.

near which the forthcoming Baghdad Railway

would pass. Locations like Baqubah, Duhok, and

area in the German city of Oberhausen. Part of

Zakho, argued Klein, comprised stable populations

the Zeche Concordia, a coal mine that reached

of able-bodied men who would be ready to under-

deep into the ground beneath a developing part of

take the work of mining and, with some training,

Oberhausen’s city center, suddenly collapsed, cre-

the industrial production that could allow the

ating a massive thirteen-hectare crater in an area

region to flourish as the new manufacturing hub of

that already had its streets laid out and contained a

the ancient world.

handful of buildings (fig. 6).21 The crater filled with

19

No two pieces of coal are created equal, and in a

In 1870, one such calamity befell a massive

groundwater and became known as the “Concor-

location with such a dearth of wood (a less efficient

diasee,” or Concordia Lake, a body of water that

and more labor-intensive energy alternative), it was

remained in the city until it was dredged ten years

also important to measure the calorific value of the

later. Both the instantaneous movement and the

coal that the expedition identified. In many cases,

devaluation of property shocked the city’s resi-

for various reasons related to the region’s geological

dents, who had until then been confident that the

history, the calorific capacity of the available coal

rapid development they were witnessing in their

was heavily compromised by water runoff and silt

city and region was an unequivocal good. One res-

from the course of the Tigris and Euphrates Rivers

ident proclaimed, “The building sites are devalued

and their tributaries. With algorithmic logic, the

and not for sale. Mortgages cannot be obtained and

report weighs the calorific output of silted coal

there is no telling when this calamity will end.”22

against the other factors: proximity to the coming

railway, the quality of the local labor pool, and the

it marked the beginning of a period of increased

nearness of ore. The report also presciently details

rigor in the engineering of mines in Germany and

the widespread presence of the century’s next great

beyond. In the 1870s and ’80s, geologists, engineers,

energy source: petroleum.

and architects worked more closely together to

examine the structural challenges faced by larger

20

The issues of land tenure that shaped the

The Concordia disaster is auspicious in that

practice of prospecting in the metals industry were

and larger mines, and these structural challenges

also important once mining had actually begun. As

were understood as relating to both the mine’s

the size and depth of mines—particularly those for

interior and the earth’s surface above it. Geologists

coal and ore—increased, so too did the pernicious

identified three different kinds of land distortion

Origin

19

Figure 6. View of the “Concordiasee” in Oberhausen, ca. 1875.

subsidence.24 Legal questions that emerged from the

Stadtarchiv Oberhausen.

geological shifts associated with mine subsidence, including who was culpable for the massive damage they could cause to buildings and other built things,

20

that occurred as a result of mining: a distortion area

again centered on land tenure. As a general rule,

(at an obtuse angle from the point of subsidence),

the state’s laws favored a definition of land owner-

a pressing area (at an acute angle from the point of

ship that extended infinitely underground, which

subsidence), and a balanced area (directly above the

stands in sharp contrast to the finite limitation of a

point of subsidence), with the pressing area being

property’s air rights. Nevertheless, the responsibility

the most injurious to existing buildings (fig. 7).23 It

for accidents that occurred underground fell on the