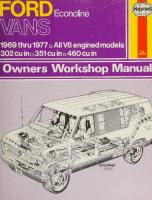

Haynes Ford Econoline Vans Owners Workshop Manual 0856963445, 9780856963445

“220 pages : 28 cm Includes index Models covered: All Econoline models from 1969 thru 1977 fitted with the 302, 351 or

124 16 22MB

English Pages 228 Year 1978

Recommend Papers

File loading please wait...

Citation preview

qd)

@ } eS 2

_—

| Gas

SE] da) ab}

@)

Ey

a

any

erry Terr ——

Dav zy)

(Ova

NES]

y) 387.

} me

|

Digitized by the Internet Archive in 2022 with funding from Kahle/Austin Foundation

https://archive.org/details/fordeconolineown0000hayn

Ford Econoline Owners

Workshop Manual by J H Haynes Member of the Guild of Motoring Writers

and Marcus Daniels Models covered: All Econoline models from 1969 thru 1977 fitted with the 302, 351 or 460 cu in V8 engine

ISBN 0 85696 344 5

© _ Haynes Publishing Group 1978

rear

All rights reserved. No part of this book may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopying, recording or by any information storage or retrieval system, without permission in writing from the copyright holder.

Printed in England

(344 -9D1)

HAYNES PUBLISHING GROUP SPARKFORD

YEOVIL

SOMERSET

distributed in the USA by

HAYNES PUBLICATIONS 861 LAWRENCE DRIVE NEWBURY PARK CALIFORNIA 91320 USA

INC

) ENGLAND

Acknowledgements Special thanks are due to the Ford Motor Company in the USA for the supply of technical information and certain illustrations. The Champion Sparking Plug Company supplied the illustrations showing the various spark plug conditions. The bodywork repair photographs used in this manual were provided by Lloyds Industries Ltd who supply ‘Turtle Wax’, ‘Dupli-Color Holts’, and other Holts range products. The Section of Chapter 10 dealing with the suppression of radio

interference, was originated by Mr |.P. Davey, and was first published in Motor magazine. Lastly, thanks are due to all those people at Sparkford who helped in the production of this manual. Particularly, Brian Horsfall and Martin Penny, who shared the mechanical work, and Les Brazier and Leon Martindale, who, between them, took the photographs. John Rose edited the text and lan Robson planned the layout of each page.

About this manual [ts aims The aim of this book is to help you get the best value from your van. It can do so in two ways. First it can help you decide what work must be done, even should you choose to get it done by a garage; the

routine random second you the

maintenance and the diagnosis and course of action when faults occur. However, it is hoped that you will also use the and fuller purpose by tackling the work yourself. This can give satisfaction of doing the job personally. On the simpler jobs it

may even be. quicker than booking the van into a garage and going there twice, to leave and collect it. Perhaps more important, money can be saved by avoiding the costs a garage must charge to cover labour and overheads.

To reduce labor costs a garage will often give a cheaper repair by fitting a reconditioned assembly. The home mechanic can be helped by this book to diagnose the fault and make a repair using only a minor

spare part. The book has drawings and descriptions to show the function of the various components so that their layout can be understood. Then the tasks are described and photographed in a step-by-step sequence so that even a novice can cope with complicated work. The jobs are described assuming only normal tools are available, and not special tools, unless absolutely necessary. A reasonable outfit of tools will be a very worthwhile investment. Many special workshop togls produced by the makers merely speed the work, and wherever

possible, guidance is given as to how to Go the job without them. On a very few occasions

components;

a special tool is essential to prevent

damage

where this is the case, its use is described. Though

to

it

might be possible to borrow the tool, such work may have to be entrusted to an official repair agent. For further information on tools and equipment refer to the Section entitled, ‘Tools and working facilities’.

Using the manual The manual is divided into twelve Chapters. Each Chapter is divided into numbered Sections which are headed in bold type between horizontal lines. Each Section consists of serially numbered paragraphs. There are two types of illustration: (1) Figures which are numbered according to Chapter and sequence of occurrence in that Chapter. (2) Photographs which have a reference number in their caption. All photographs apply to the Chapter in which they occur so that the reference figure pinpoints the pertinent Section and paragraph number. Procedures, once described in the text, are not normally repeated. If it is necessary to refer to another Chapter the reference will be given in Chapter number and Section. Cross-references given without use of the word ‘Chapter’ apply to Section and/or paragraphs in the same Chapter, eg. ‘see Section 8’ means also ‘in this Chapter’. When the left or right side of the car is mentioned it is as if one is seated in the driver's seat looking forward.

Although

every care has been taken in the preparation of this .

manual the publishers and author cannot accept responsibility for any errors in, or omissions from, the information given.

Contents Section Introductory sections

—_=

2

Engine

Cooling system

Page 5

Routine

5

Tools and working facilities

12

Jacking and towing

6

ne

19

Refitting

38

27 30

Fault diagnosis

39

Draining Flushing

41 41

Filling Radiator Thermostat

41 43 43

Temperature gauge Fault diagnosis

Exhaust system

Emission control systems

Carburetors

50 ~——Fault diagnosis

ea

ee

Re

Contact breaker points Distributor

75 76

Spark plugs

78

85 86 86 86 88 92 92 94 95 97, 98 103

ee

eee ee eee

Braking system

ee

10

Electrical system

Suspension and steering

Bodywork and underframe

ee

64 71

Re

RS

eR

Let

PG

Ignition timing Fault diagnosis

78 83

Release bearing —_ Linkage Pedal Fault diagnosis

89 89 89 90

Part B Automatic transmission ‘Fluid level checking Removal and refitting Shift linkage Fault diagnosis

100 101 103 103

‘Fault diagnosis

108

106 106

Axleshaft Rear axle ee Bleeding Flexible hoses

109 113

Differential Fault diagnosis

3 116

119 119

Master cylinder Brake pedal

128 131

Disc brake pads Disc brake calipers Front and rear drum brakes

119 123 123

Parking brake Brake booster Fault diagnosis

131 133 133

Battery

137

Windshield wiper and washer

153

Alternator

138

Horn

55

Starter motor

140

Radios and tape players

156

Front Front Front Rear

wheel bearings axle shock absorber suspension

Maintenance

ee

64

Removal and refitting

i 12

‘

Universal joints

Fuses and relays Lights and switches a 11

ee

59

ee

Part A Manual transmission Removal and refitting Dismantling Examination and renovation Input and output shaft Reassembly Gearshift linkage Fault diagnosis

Neen

ee

eee

50

Manual and automatic transmission

9

45 45

48

6

Rear axle

8

43 44

Fuel pump

Adjustment Removal Overhaul Inspection Refitting

8

Water pump _ Drivebelts

ee

Clutch

Driveshaft

8

Removal

5

7

maintenance

Examination and renovation Reassembly

Fuel tank

a

a 4 Ignition system

Page

Buying spare parts

I 3 Carburetion; fuel, exhaust and Thermostatic air cleaner

emission control systems

Section

Introduction to the Econoline

ss

ss

Fault diagnosis 142 142 EE

159 EEE

182 187 187 187

Rear shock absorber Steering and tires Wheels Fault diagnosis

189 189 92 192

193

Fenders and bumpers

210

210 Heater 195 Repairs 215 196 =Air conditioning Doors and windows 205 Radiator grille SsrrinirrrnnTnnnIT =il : P Metric conversion tables Index

jenuew Siu} 10} aj914aA yOefo1d ay} Se pasn auljoUOd A poy 9yt

Introduction to the Econoline The Ford Econoline was first introduced in 1961 and known as the E-100 Series. It was available with either a van, club wagon or pick-up body and a choice of three V6 engines of varying capacities. This manual covers all models equipped with the V8 engine which became available in 1969. This engine has a capacity of 302 cu in and was an optional fit on all models until 1974 when it was replaced by the larger 351 cu in or 460 cu in V8 engines. The three engines are very similar in design, comprising two banks of four cylinders opposed to each other in a ‘V’ configuration of 90°. The crankshaft is supported by five shell type main bearings and the connecting rod bearings are of the same type. The valve gear is actuated by a single camshaft located in the center of the ‘V’ shaped cylinder block and is chain driven from

the crankshaft.

The standard

transmission

on all models

is a manual

shift three-

speed gearbox, with a cable operated clutch. Automatic transmission is available as an optional extra. The power output is transmitted to the rear axle by a single tubular driveshaft on models fitted with manual transmission and a two-piece driveshaft with a center support bearing in the case of automatic transmission. The front suspension is extremely robust and consists of twin ‘I’ beam axles pivoted at the inner ends and attached to the chassis by coil springs and radius rods. Damping is effected by telescopic shock absorbers. The rear suspension is the conventional semi-eliptical leaf spring system with telescopic shock absorbers. Short or long wheelbase versions are available and with a gross vehicle weight capacity ranging from 2,300 to 11,000 Ib the Econoline models offer a wide choice to those seeking a business/pleasure vehicle.

Buying spare parts and vehicle identification numbers Buying spare parts Spare parts are available from many sources although they generally fall into two categories — those items which are supplied by a Ford dealer and those which are supplied by auto accessory stores. In some cases the two facilities may be combined with an over-thecounter service and a pre-pack display area. In some cases it may be possible to obtain parts on a service-exchange basis but, where this can be done, always make sure that the parts returned are clean and intact. Our advice regarding spare parts purchase is as follows: Ford dealers: This is the best source of supply for major items such as transmissions, engines, body panels, etc. It is also the only place to obtain parts if your vehicle is still under warranty, since the warranty may be invalidated if non-Ford parts are used. Auto accessory stores: Auto accessory stores are able to supply practically all of the items needed for repair, maintenance, tune-up and customizing. This is not only true for vehicle but also for tools and test equipment. Whichever source of spare parts is used it will be essential to provide information concerning the model and year of manufacture of your vehicle.

Vehicle identification The vehicle identification or warranty number is stamped on a plate

SERIES-LETTER AND FIRST TWO DIGITSOF SERIES DESIGNATION

ASSEMBLY ~— PLANT

HH

Vehicle loading information Care must be taken not to exceed the maximum load carrying capacity of your vehicle. Always distribute the cargo as evenly as possible over the floor area. Overloading the rear of the vehicle will reduce front wheel traction and can cause serious handling problems. To ensure correct loading a safety certification label is attached to the driver's rear door pillar (see example). This gives the maximum total weight permissible for your vehicle and is known as the GVWR (Gross Vehicle Weight Rating). The maximum loading of the front and rear axles is also shown and this is identified as GAWR (Gross Axle Weight Rating). It should be noted that if one axle is loaded to the maximum figure the other axle must not be loaded to such an extent that the combined axle weight loadings exceed the maximum permissible gross weight of the vehicle. Remember to include the weight of the driver, passengers and fuel when calculating the gross vehicle weight.

REAR

AXLE

SAFETY

CERTIFICATION

LABEL

TYPE/G.V.W.

“Z1F

€26

If it becomes necessary to order new parts for your vehicle, make a note of the warranty number and take it along to the local Ford dealer.

TRANSMISSION

UNIT NUMBER

ENGINE

located on the rear face of the left front door lock panel. The plate also

gives engine and transmission code numbers along with other relevant information (see example).

GCAVR

OR GVWR

LOSPD

CAPACITY

1S EXC

FEDED MADE

A00000

IN

USA TR» INS * A>

— SAMPLE MFD. BY FORD MOTOR CO. IN U.S.A. DATE 09/75 GVWR 6050 GAWR FRONT 2850 REAR 3460 THIS VEHICLE CONFORMS TO ALL APPLICABLE FEDERAL MOTOR VEHI CLE SAFETY STANDARDS IN EFFECT ON DATE OF MANUFACTURE SHOWN ABOVE E14HHA00000 TRUCK

LE

MAXIMUM

3,460 LBS. MAXIMUM

Veh. |dent

Body

No

Color

STV

Trim

PRE

eee

Trans

6,050 LBS. > MAXIMUM RECOMMENDED MAXIMUM GROSS VEHICLE WEIGHT RATING

COLOR

WHEELBASE

CODE

CAB OR BODY TYPE/ TRIM CODE

Vehicle rating plate

DISTRICT CODE SPECIAL ORDER NUMBER

Safety certification and weight data plate

Axle

Oso

Jacking and towing Jacking If it becomes necessary to raise the vehicle off the ground in order to change a wheel or carry out maintenance tasks, do not raise the vehicle by the bumpers. To change a front wheel, place the jack under the axle radius arm as shown in the illustration ‘A’ or ‘B’, depending on the model. To change a rear wheel, place the jack under the axle as shown in illustration ‘C’. Always ensure that the vehicle is standing on a level surface and that the wheels, other than the one being changed or removed are chocked. Loosen the wheel nuts in a diagonal sequence and tighten in a similar manner.

Towing The following procedures should be observed before towing is considered as an incorrect method could ruin the transmission due to lack of lubrication.

A

Front jacking point for Series E100 and 150

1 Make

sure the parking brakes

are released

and the transmission

gears are in neutral. 2 Ensure that the transmission

and rear axle are working properly before towing. If the rear axle is defective it will be necessary to raise the rear of the vehicle. If the transmission is defective the driveshaft. can be removed or the rear wheels raised. 3 When towing with the rear wheels raised, fit a locking device to the front wheels to prevent them turning. 4 \|f the vehicle is fitted with an automatic transmission and the rear wheels are on the ground, do not tow further than 15 miles or at a speed greater than 30 mph. If this is not possible, disconnect the driveshaft or raise the rear wheels. 5 It is important that the towing device be fastened only to the brackets that attach the bumper to the frame, and must be passed under the bottom edge of the bumper.

B Front jacking point for Series E250 and 350

C Rearjacking point

Use of English As this book has been written in England, it uses the appropriate English component names, phrases, and spelling. Some of these differ from

those used inAmerica. Normally, these cause no difficulty, but to make sure, a glossary is printed below. In ordering spare parts remember the parts list will probably use these words:

—

English

American

English

American

Aerial Accelerator Alternator

Antenna Gas pedal Generator (AC)

Anti-roll bar Battery Bodywork Bonnet (engine cover) Boot lid Boot (luggage compartment) Bottom gear Bulkhead Cam follower or tappet Carburettor Catch

Countershaft Primary shoe Latches

Stabiliser or sway bar Energizer Sheet metal Hood Trunk lid Trunk 1st gear Firewall Valve lifter or tappet Carburetor Latch

Layshaft (of gearbox) Leading shoe (of brake) Locks Motorway Number plate Paraffin

Freeway, turnpike etc License plate Kerosene

Petrol

Gasoline

Petrol tank ‘Pinking’ Propeller shaft

Gas tank ‘Pinging’ Driveshaft

Quarter light Retread

Quarter window Recap

Reverse Rocker cover

Back-up Valve cover

Choke/venturi

Barrel

Roof rack

Car-top carrier

Circlip

Snap-ring

Saloon

Sedan

Clearance

Lash

Seized

Frozen

Crownwheel Disc (brake)

Ring gear (of differential) Rotor/disk

Side indicator lights Side light

Side marker lights Parking light

Drop arm Drop head coupe

Pitman arm Convertible

Silencer Spanner

Muffler Wrench

Dynamo Earth (electrical) Engineer's blue Estate car Exhaust manifold

Generator (DC) Ground

Sili panel (beneath doors) Rocker panel Split cotter (for valve spring cap) Lock (for valve spring retainer) Split pin Cotter pin Steering arm Spindle arm Sump Oil pan

Prussian blue Station wagon Header

Fast back (Coupe)

Hard top

Tab washer

Tang; lock

Fault finding/diagnosis Float chamber

Trouble shooting Float bowl

Tailgate Tappet

Liftgate Valve lifter

Free-play

Lash

Thrust bearing

Throw-out bearing

Freewheel

Coast

Top gear

High

Gudgeon pin Gearchange

Piston pin or wrist pin Shift

Trackrod (of steering) Trailing shoe (of brake)

Tie-rod (or connecting rod) Secondary shoe

Gearbox Halfshaft

Transmission Axleshaft

Transmission Tyre

Whole drive line Tire

Handbrake

Parking brake

Van

Panel wagon/van

Hood

Soft top

Vice

Vise

Hot spot Indicator Interior light

Heat riser Turn signal Dome lamp

Wheel nut Windscreen Wing/mudguard

Lug nut Windshield Fender

Miscellaneous points

An ‘oil seal’ is fitted to components lubricated by grease! A ‘damper’ is a ‘shock absorber’, it damps out bouncing, and absorbs shocks of bump

impact. Both names

; haphazardly. Note that British drum brakes are different from the Bendix type that is common in America, so end furthest from the hydraulic wheel cylinder is on a pivot; interconnection between the shoes as on the phrase ‘Primary’ or ‘Secondary’ shoe does not apply. A shoe is said to be ‘Leading or ‘Trailing’. A drum, as it rotates forward, reaches the shoe at the end worked by the hydraulic cylinder before the and this one has no self servo from the wrapping effect of the rotating drum.

are correct, and both are used

on different descriptive names result. The shoe Bendix brakes is most uncommon. Therefore

‘Leading’ shoe is one on which a point on the anchor end. The opposite is a ‘Trailing’ shoe,

Routine

maintenance

/ntroduction The Routine Maintenance instructions are basically those recommended by the vehicle manufacturer. They are supplemented by additional maintenance tasks proven to be necessary.

Brakes Check

reservoir fluid level. If this has fallen noticeably,

check for

fluid leakage (photo) Check for satisfactory brake operation

It must be emphasised that if any parts of the engine or its ancillary

equipment involved with emission control are disturbed, cleaned or adjusted, the vehicle must be taken to the local Ford dealer for checking to ensure that it still meets legal requirements. Tasks in the maintenance instructions marked with an asterisk (*) must be entrusted to a Ford dealer. The reader should also familiarise himself with the conditions of the vehicle warranty if the vehicle is less than 5 years old. If the conditions of the warranty are broken or an accurate record of servicing not kept, the warranty can become invalidated. On later models three maintenance schedules, A, B or C, are given. These cover the variations in servicing requirements for vehicles sold in different states and the type of engine fitted. To check which maintenance schedule applies to your vehicle, refer to the emission control data decal located in the engine compartment, (see example on this page). In the case of the earlier E-300 models, carry out the maintenance

Lights, wipers, horns, instruments Check operation of all lights Check operation of windscreen wipers and washers Check that the horn operates Check that all instruments and gauges are operating Engine compartment

Check the engine oil level; top-up if necessary (photos) Check radiator coolant level Check battery electrolyte level

All models Every 3000 miles (50000 km). or 3 months

tasks listed under 4,000 mile (5,600 km) heading and then continue

The following maintenance items must be carried out at this mileage/time interval if the vehicle is being operated in severe condi-

with the items listed under Schedule ‘C’.

tions. These are considered to be:

a) Outside temperature remains below 10°F (—12-2°C) for 60 days or more and most trips are less than 10 miles. b) /f a trailer having a total weight of more than 2000 /b is towed over long distances. c) Extended periods of idling or low speed operation.

All models Every 250 miles (400 km), weekly or before a long journey Steering Check tire pressures (when cold) Examine tires for wear and damage Check steering for smooth and accurate operation

See)

For normal vehicle operation these service items may be carried out at the prescribed service intervals.

TSS

ae

ENG-NE FAMILY, 23 FGK/AIR CATALYST «1-CEF) ENGINE DISPLACEMENT CIO

MAKE ALL AOJUSTMENTS OPERATING TEMPERATURES

140

- PARK PLUG

QISTR.BUIOR

AGRE 52

BREAKERLESS

CHOKE HOUSING NOTCH SETTING

CI6IN

INDEX Nels.

:

~[ AUTO: | MANUAL Ff DRIVE | NEUTRAL MOVE oDEG BTC 1ODEGBIDC UAL

se Meee te Sane eee

2950)

THE LIMITER CAP(S) CONSULT T RVICE MAN FOR DESCRIPTION OF ART. ENRICHMENT METHOD OF IDLE MIXTURE A NI TO BE USED: ONLY DURING TUNE UPS MAJOR CARBURETOR REPAIRS IDLE MIXTUB ST BE MEASURED W!TH THERMACTOR AIR: Q

oes

INITIAL

AND

TE

SE PA REGULATIONS APPLICABLE

TIMipys

PL

FADJUST WITH HOSES DISCONNECTED D AY THE DISTRIBUTOR: P ;

RENCE TO A/C THROTTLE SOLENOID THERMACTOR R AND DECEL VALVE APPLICABLE ONLY. IF THE £NGINE 'S SO EQUIPPED. CONSULT -SERVICE PUBLICATIONS‘ FOR FURTHER INSTRUCTIONS ON TIMING ANO IDLE SET

8

ee

-WITH ENGINE AT NORMAL A/C AND HEADLIGHTS OFF

CURB IOLE ADJUST WITH THROTTLE SOLENOID POS|TIONER ENERGIZED: THERMACTOR AIR ON. ALL VACUUM HOSES CONNECTED AND AIR CLEANER IN POSITION WHENEVER -CURB IDOLE IS RESET CHECK AND ADJU9 | THE DECEL VALVE ACCORDING TO’ THE SERVICE

i

IGNITION TIMING -° TIMING RPM CPM

032-

MAN/TRANS _ : -AUTO/TRANS

TRANSMISSION

CORB IDLE

GAP

EX

121975 MODEL YEAR NEW MOTOR VEHICLES

2 CONFORMS TO THE STATE OF CALIFORNIA CERTIFICATION “IANOARDS

S ORL MUTOR COMPANY

FEAR NEW MOTOR VEHIC

APPLIC ABLE-TC1976 MODLL

>

76EG.3C 465. CA

Example of an emission control information decal

CODE LETTER

Routine maintenance

©

rr

Complete the checks in the weekly inspection plus the following: Change the engine oil (photo) Fit a new oil filter (photo)

E-300 models only Every 4000 miles (5600 km) or 4 months whichever occurs first Change the engine oil and filter. Lubricate and free up the exhaust control valve. Adjust the curb idle speed

Schedules A and B Every 5000 miles (8000 km) or 5 months, whichever occurs first

Renew the engine oil and filter Check the ignition timing Adjust engine idle speeds and mixture *Check and adjust fuel deceleration valve *Check throttle solenoid operation Check brake master cylinder fluid level Adjust clutch pedal free-play, if necessary

Every 6000 miles (10000 km) or 6 months, whichever occurs first

Change engine oil and filter (every 4000 miles (5600 km) on E-300 models) Check transmission fluid levels (photo) Check brake fluid level Adjust clutch pedal free-play, if necessary *Check fuel deceleration valve if fitted *Adjust engine idle speed and mixture Check the torque of intake manifold bolts Lubricate exhaust control valve if fitted Check operation of throttle and choke linkage Renew fuel filter Check all drivebelt tensions Lubricate front axle spindle pins and steering linkage

Schedules A and B Every 10000

miles ((16000 km) or 10 months, whichever occurs

first

Change engine ol!

General view of engine from inside the cab

ee

eee

Schedule C Every 12000

miles (20000 km) or 12 months, whichever occurs

first

Adjust engine valve clearances Check carburetor air cleaner element Renew all spark plugs Inspect spark plug wires *Check spark control systems and delay valve *Check EGR system and delay valve Check condition of coolant Inspect all drivebelts for wear and renew if necessary *Inspect evaporative emission canister Check the torque of all engine driven accessory mounting bolts Check front suspension and steering linkage for abnormal slackness or damaged seals *Adjust automatic transmission bands Inspect exhaust system and heat shields for corrosion or damage

Schedules A and B Every 15000 first

Schedule C

ee

miles (24000 km) or 15 months, whichever occurs

Note: The following checks are Schedule B only: Check the torque of inlet manifold bolts Lubricate and check exhaust control valve Check condition of coolant Check drivebelt tensions Check PCV system hoses *Check thermactor system

Renew spark plugs Inspect spark plug HT cables Check ignition timing Inspect distributor cap and rotor *Check spark control system and delay valve *Check carburetor idle speed and mixture Check throttle and choke linkage Check air cleaner element *Check air cleaner temperature control and delay valve Renew fuel system filter Check and adjust valve clearances Check the torque of engine driven accessory mounting bolts Note: The following checks are for A and B Schedules Inspect the exhaust system and heat shields for corrosion damage

or

the

automatic

transmission

Topping up the engine oil level

Checking level

Rear axle filler plug

Engine oil pan drain plug

Checking the brake fluid level

Check the power steering reservoir fluid level (when fitted)

Location of engine oil filter

t

V—

*

Upper axle pin grease nipple

Lower axle pin grease nipple

Steering arm grease nipple (typical)

fluid

11

GEARSHIFT

CONTROL

LEVERS

STEERING

DRAG LINK FITTING a

: alee

KING PIN — 2 FITTINGS ON EACH SIDE

&2) FITTING

DRAG

FRONT

LINK FITTING

BUUTING

MANUAL

TRANSMISSION

JOINT

SPLINE

UNIVERSAL

UNIVERSAL

PLUG

LINKAGE

UNIVERSAL

UNIVERSAL

BEARINGS

FITTING 7)

TRANSMISSION

WHEEL

FITTING

FITTING

Chassis

lubrication

JOINT FITTING

chart

JOINT FITTING

JOINT

FITTING

DIFFERENTIAL

PLUG

Recommended

lubricants and fluids

Component

Description

Ford Specification

Component

Description

Ford Specification

Hinges, hinge check and pivots

Polyethylene Grease

ESB-M1C106-B

Automatic

Ford Automatic Transmission fluid

ESW-M2C33-F Type F

Brake master cylinder Front suspension ball joints, front wheel bearings and

Heavy Duty Brake Fluid Ball Joint and Multi-purpose Grease

ESA-M6C25-A

Ford Manual

ESW-M2C83-B

ESA-M1C75-B

Engine

Transmission Oil Engine Oil*

ESE-M2C101-C

Polyethylene

ESB-M1C106-B

Engine coolant

Ford Cooling System Fluid

ESE-M97B18-C

ESB-M2C20-A

Steering gear housing (manual and

Steering Gear Oil

ESW-M1C87-A

Silicone Lubricant

ESR-M1314-A

transmission

Manual transmission

clutch linkage Hood latch and auxiliary catch

Grease

Lock cylinders

Lock Lubricant

power) Rear axle:

Door weatherstrip Conventional Traction-Lok

Power steering (Pump reservoir)

Hypoid Gear Oil Hypoid Gear Oil

ESW-M2C105-A ESW-M2C119-A

Power Steering Fluid

ESW-M2C128-B

*Note: engine oil of a viscosity suitable for the ambjent temperature must be used. Consult the operators handbook supplied with your vehicle.

12

Routine maintenance Inspect fuel tank filler cap, and vapor lines for leakage or deteriora-

Check transmission fluid levels Check clutch pedal free-play and adjust if necessary Inspect front suspension and steering for looseness or damaged seals Have your local Ford dealer adjust the automatic transmission bands Check brake pads and linings for wear

tion

Renew air cleaner element (photos)

Schedule C Every 24000 miles (40000 km) or 2 years, whichever occurs first

Schedule C Every first

18000

miles (30000

km) or 18 months,

whichever

occurs

Inspect distributor cap and rotor Check tightness of rear spring mountings

Schedules A, B and C

ScheduleA Every 20000 first)

Dismantle, lubricate and adjust front wheel bearings Renew crankcase filter in air cleaner Renew air cleaner element Inspect filler cap and fuel line for deterioration or leakage *Check thermactor system if fitted Check cooling system hoses for leakage Inspect disc pads and rear brake lining for wear Inspect all brake hoses and lines

miles (32000 km) or 20 months, ,

Carry out the maintenance tasks listed vehicles at 15000 miles, plus the following:

whichever

for schedule

A

occurs

and

B

Renew the PCV valve Clean PCV system hoses Renew crankcase filter in air cleaner *Inspect evaporative emission canister

Every 30000

miles (50000

km) or 30 months,

whichever

occurs

first

Lubricate front suspension and steering linkage Drain and refill automatic transmission fluid Renew coolant Examine all brake hoses and pipes and renew if necessary Check wheel cylinders and master cylinder for leaks and

renew

seals where necessary Renew brake fluid

Tools and working facilities Introduction A selection of good tools is a fundamental requirement for anyone contemplating the maintenance and repair of a motor vehicle. For the owner who does not possess any, their purchase will prove a considerable expense, offsetting some of the savings made by doing-ityourself. However, provided that the tools purchased are of good quality, they will last for many years and prove an extremely worthwhile investment. To help the average owner to decide which tools are needed to carry out the various tasks detailed in this manual, we have compiled three lists of tools under the following headings: Maintenance and minor repair, Repair and overhaul, and Special. The newcomer to practical mechanics should start off with the Maintenance and minor

repair tool kit and confine himself to the simpler jobs around the vehicle. Then, as his confidence and experience grows, he can undertake more difficult tasks, buying extra tools as, and when, they are needed. In this way, a Maintenance and minor repair tool kit can be built-up into a Repair and overhaul tool kit over a considerable period of time without any major cash outlays. The experienced do-ityourselfer will have a tool kit good enough for most repair and overhaul procedures and will add tools from the Specia/ category when he feels the expense

is justified by the amount

of use these tools will be

put to.

It is obviously not possible to cover the subject of tools fully here. For those who wish to learn more about tools and their use there is a book entitled How to Choose and Use Car Tools available from the publishers of this manual.

Maintenance and minor repair tool kit The tools given in this list should be considered as a minimum requirement if routine maintenance, servicing and minor repair operations are to be undertaken. We recommend the purchase of combination wrenches (ring one end, open-ended the other); although more expensive than open-ended ones, they do give the advantages of both types of wrench.

Combination wrenches - 3 in, # in, + in, & in, in. AF Adjustable wrench - 9 inch Engine oil pan/gearbox/rear axle drain plug key (where applicable)

Spark plug wrench (with rubber insert) Spark plug gap adjustment tool Set of feeler gauges Brake adjuster wrench Brake bleed nipple wrench

Screwdriver - 4 in long x } in dia (flat blade) Screwdriver - 4 in long x + in dia (cross blade) Combination pliers - 6 inch Hacksaw, junior Tire pump Tire pressure gauge

Grease gun Oil can Fine emery cloth(1 sheet) Wire brush (small) Funnel (medium size)

Repair and overhaul tool kit These tools are virtually essential for anyone undertaking any major repairs to a motor vehicle, and are additional to those given in the Maintenance and minor repair list. included in this list is a comprehensive set of sockets. Although these are expensive they will be found invaluable as they are so versatile - particularly if various drives are included in the set. We recommend the 4 inch square-drive type, as this can be used with most proprietary torque wrenches. If you cannot afford a socket set, even bought piecemeal, then inexpensive tubular box wrenches are a useful alternative. The tools in this list will occasionally need to be supplemented by tools from the Spec/a/ list.

Sockets (or box wrenches) to cover range in previous list

Reversible ratchet drive (for use with sockets) Extension piece, 10 inch (for use with sockets) Universal joint (for use with sockets) Torque wrench (for use with sockets) Se/f-grip wrench - 8 inch Ball pein hammer

Soft-faced hammer, plastic or rubber

ie

Tools and working eee ee facilities a

Rl

Screwdriver - 6 in long x % in dia (flat blade) Screwdriver - 2 in long x % in square (flat blade) Screwdriver - 14 in long x in dia (cross blade) Screwdriver - 3 in long x ¢ in dia (electricians) Pliers - electricians side cutters Pliers - needle nosed Pliers - circlip (internal and external)

Cold chisel - 4 inch Pea (this can be made by grinding the end of a broken hacksaw

lade

13

rr

such as screwdrivers and pliers is a good idea. Store all normal wrenches and sockets in a metal box. Any measuring instruments, gauges, meters, etc., must be carefully stored where they cannot be damaged or become rusty. Take a little care when tools are used. Hammer heads inevitably become marked and screwdrivers lose the keen edge on their blades from time-to-time. A little timely attention with emery cloth or a file will soon restore items like this to a good serviceable finish.

Use of tools

Scraper (this can be made by flattening and sharpening one end of a piece of copper pipe) Centre punch

Throughout this book various used, such as: ‘Drive out the bearing’.

Pin punch

‘Undo the flange bolts evenly and diagonally’. When two parts are held together by a number of bolts round their edge, these must be tightened to draw the parts down together flat.

Hacksaw Valve lapping tool

Steel rule/straight edge Allen keys Selection of files Wire brush (large) Axle stands

Special tools The tools in this list are those which are not used regularly, are expensive to buy, or which need to be used in accordance with their manufacturers instructions. Unless relatively difficult mechanical jobs are undertaken frequently, it will not be economic to buy many of these tools. Where this is the case, you could consider clubbing together with friends (or a motorists club) to make a joint purchase, or borrowing the tools against a deposit from a local repair station or tool hire specialist. The following list contains only those tools and instruments freely available to the public, and not those special tools produced by the vehicle manufacturer specifically for its dealer network. You will find

occasional references to these manufacturers special tools in the text of this manual. Generally, an alternative method of doing the job without the vehicle manufacturers special tool is given. However,

sometimes, there is no alternative to using them. Where this is the case and the relevant tool cannot be bought or borrowed you will have to entrust the work to a franchised repair station. Valve spring compressor

Piston ring compressor Balljoint separator

Universal hub/bearing puller Impact screwdriver Micrometer and/or vernier gauge Carburetor flow balancing device (where applicable)

Dial gauge Stroboscopic timing light Dwell angle meter/tachometer Universal electrical multi-meter Cylinder compression gauge Lifting tackle Trolley jack Light with extension lead

describing

techniques

are

They must be slackened evenly to prevent the component warping. Initially the bolts should be put in finger-tight only. Then they should be tightened gradually, at first only a turn each; and diagonally, doing the one opposite that tightened first, then one to a side, followed by another opposite that, and so on. The second time each bolt is tightened, only half a turn should be given. The third time round, only quarter of a turn is given each, and this is kept up till tight. The reverse sequence is used to slacken them. If any part has to be ‘driven’, such as a ball bearing out of its housing, without a proper press, it can be done with a hammer provided a few rules for use of a hammer are remembered. Always keep the component being driven straight so it will not jam. Shield

whatever

is being

hit from

damage

by the hammer.

Soft headed

hammers are available. A drift can be used, or if the item being hit is soft, use wood. Aluminium is very easily damaged. Steel is a bit better. Hard steel, such as a bearing race, is very strong. Something threaded at the end must be protected by fitting a nut. But do not hammer the nut: the threads will tear. If fevering items with makeshift arrangement, such as screwdrivers, irretrievable damage can be done. Be sure the lever rests either on something that does not matter, or put in padding. Burrs can be filed off afterwards. But indentations are there for good, and can cause leaks. When holding something in a vise, the jaws must go on a part that is strong. If the indentation from the jaw teeth will matter, then lead or fibre jaw protectors must be used. Hollow sections are liable to be crushed. Nuts that will not undo will sometimes move if the wrench handle is extended with another. But only extend a ring wrench, not an open jaw one. A hammer blow either to the wrench, or the bolt, may jump it out of its contact: the bolt locally welds itself in place. In extreme cases the nut will undo if driven off with drift and hammer. When reassembling such bolts, tighten them normally, not by the method needed to undo them. For pressing things, such as a sleeve bearing into its housing, a vise, or an electric drill stand, make good presses. Pressing tools to hold each component can be arranged by using such things as socket wrenches, or short lengths of steel water pipe. Long bolts with

washers can be used to draw things into place rather than pressing

Buying tools For practically all tools, a tool factor is the best source since he will have a very comprehensive range compared with the average repair station or accessory shop. Having said that, accessory shops often

offer excellent quality tools at discount prices, so it pays to shop around. Remember, you don't have to buy the most expensive items on the shelf, but it is always advisable to steer clear of the very cheap tools. There are plenty of good tools around at reasonable prices, so ask the proprietor or manager of the shop for advice before making a purchase.

Having purchased a reasonable tool kit, it is necessary to keep the tools in a clean serviceable condition. After use, always wipe off any dirt, grease and metal particles using a clean, dry cloth, before putting the tools away. Never leave them lying around after they have been eeDr Eee ea oa A

them. There are often several ways of doing something. If stuck, stop and think. Special tools can readily be made out of odd bits of scrap. Accordingly, at the same time as building up a tool kit, collect useful bits of steel. Normally all nuts or bolts have some locking arrangement. The most common is a spring washer. There are tab washers that are bent up. Castellated nuts have split pins. Self-locking nuts have special crowns

that resist shaking loose. Self-locking nuts should not be reused, as the self-locking action is weakened as soon as they have been loosened at all. Tab washers should only be reused when they can be bent over in a new place. If you find a nut without any locking arrangement, check to see what it is meant to have.

Working facilities Not to be forgotten when discussing tools, is the workshop itself. If

Care and maintenance of tools

Pe

phrases

See

Se

EPA

eh ie Pee

vote oY 3

anything

more

than

routine

maintenance

is to be carried

out, some

form of suitable working area becomes essential. It is appreciated that many an owner mechanic is forced by circumstances to remove an engine or similar item, without the benefit ofa

qarane

nr warkchonn

Waving

donne thie

any

renaire chould

alwavs

14

Tools and working facilities

be done under the cover of a roof. Wherever possible, any dismantling should be done on a clean flat workbench or table at a suitable working height. Any workbench needs a vise: one with a jaw opening of 4 in (100 mm) is suitable for most jobs. As mentioned previously, some clean dry storage space is also required for tools, as well as the lubricants, cleaning fluids, touch-up paints and so on which become necessary.

Another item which may be required, and which has a much more

general usage, is an electric drill with a chuck capacity of at least & in (8

mm). This, together with a good range of twist drills, is virtually essential for fitting accessories such as wing mirrors and back-up lights. Last, but not least, always keep a supply of old newspapers and clean, lint-free rags available, and try to keep any working area as clean as possible.

Wrench jaw gap comparison table Jaw gap (in.)

Wrench size

Jaw gap (in.)

Wrench size

0-250 0:275

4 in. AF 7 mm AF

0-944

24 mm AF

: 0.315 0-340

311/32 mmmm AFin. AF;

0-354

9 mm AF

0-375 0-393 0-433 0-437 0-445 0-472 0-500 0-512 0-525 0-551 0-562 0-590 0-600 0-625 0-629 0-669 0-687 0-708 0-710 0:748 0-750 0:812 0-820 0-866 0.875 0-920

3 in. AF 10 mm AF 11 mm AF % in. AF 3 in. Whitworth;4 in. 12 mm AF 3 in. AF 13 mm AF z in. Whitworth; 3 in. 14 mm AF 2% in. AF 15 mm AF 3% in. Whitworth; 2 in. 3 in. AF 16 mm AF 17 mm AF in. AF 18 mm AF 3 in. Whitworth; % in. 19 mm AF 3 in. AF in. AF % in. Whitworth; 4 in. 22 mm AF $ in. AF + in. Whitworth; 2 in. 85 in, AF

0-937

4 in. Whitworth

BSF

1-000

1 in. AF

1-010

2 in. Whitworth; 2 in. BSF

1:023

26 mm AF

1-062 1-100 1-125

136 in. AF; 27 mm AF 2 in. Whitworth; 2 in. BSF 13 in. AF

1-181

30 mm AF

1-200

2 in. Whitworth; 2 in. BSF

1:259

32 mm AF

1-300

3 in. Whitworth; Z in. BSF

1-390

#2 in. Whitworth; #8 in. BSF

1.417

36 mm AF

1-437 1-480 1-500 1-574

14 in. AF % in. Whitworth; 1 in. BSF 14 in. AF 40 mm AF; 2 in. Whitworth

1-614

41 mm AF

1-670

1 in. Whitworth;

1-811

46 mm AF

1-812 1-860

172 in. AF 13 in. Whitworth; 14 in. BSF

1-968

50 mm AF

2-000 2.050 2-165 2-362

2 in. AF 13 in. Whitworth; 12 in. BSF 55 mm AF 60 mm AF

1-250 1312

BSF

BSF

1-625

1-687 BSF

1-875 BSF

BSF

12 in. AF

1S in. AF

1 Sin. AF

112 in. AF

13 in. BSF

1 Zin. AF

Chapter 1/Engine Contents

Camshaft and camshaft bearings — examination and renovation

Si

MANO

16

Enginemefittingie

Connecting rods and piston pins — examination and renovation . oe -ck).c ce Seco Crankshaftdamper— removal!

30 11

Engine'removall— general) svicee same Engine removal — models from 1974 up

a ok ce te eee ais ..............-45

oy 4

Crankshaft — examination and renovation ..............00 Crankshaft (main) bearings and connecting rod bearings — ete eeel a) ees e-msnirrse examinationiand renovations ..............0000005 Crankshaft rear oil seal—removal

26 er 21

Enginememovall— models iti inl Oi me tenet e surreal tesserae Faliltciagnosis engines maseasns ciate asia. tata en eeace ate Elywheel=removal @2 fin ham. Ccuweeee ae wien aes rein Flywheel ring gear — examination andrenovation ...........

3 49 12 35

.............

28

Front: coven—removal,

........

37

Lubrication and crankcase ventilation systems — description

mee

Camshaft—removalij.as.0.

ee

eerie

Cylinder bores — examination and renovation

Cylinder heads and piston crowns — decarbonisation

ies

ciscsis em Mirren

Enginelancillaries—removal

....... se

SiR Mea

«21

ee

cic noe

.ahes aie

9

Main bearings and crankshaft —removal

Oil filter—removalrand refitting

ae

ee

sei.)

820i bari inspection. 1

Oil pan=removalles

ie

6

Oil pump —HovVerNaull

tan

meen oases toes verce

meer rel sc

7

ie ear ier genet ee

niet

.........

Cylinder heads — removal with engine out ................ DOScriptioneaacrumcrmn

25. 5 5c saws

...........

Cylinder heads — dismantling of valves and springs

Cylinder heads — removal with engine invehicle

tie tee

seme

ee

oe

terete,

re mere

24

case ee

mre

ee cae

ke coneee he

nero) ardent os Meee

13

eens ae

36 lie/ 20 19 29 18 34 15 45 32 10 33

DUM Pinetree ruca ke oe

41

Valvellashi= adjustment scre citi cet-min- munca

43 42

...........+... Valve lifters — examination andrenovation scaces pen crcnicicneat a aan cere e eee mene Valveilifters'— removal) Valves and valve seats — examination and renovation ........

nicl Gut Byes ott awe 8 @ tepals fous F Gls ola whe

Specifications 302 cu in, 351 cu in or 460 cu in, eight cylinder V configuration ohv

Engine types

Engine data (302 cu in) General 8.0:1 4 in (101.6 mm) 3 in (76 mm)

Compression ratio Stroke

1,5,4,2,6,3,7,8 40 — 60 Ib/in? (2.8 — 4.2 kg/cm’)

Firing order

Oil pressure (hot)

Cylinder block 4.0004 — 4.0052 in (101.61 — 101.73 mm) 0.001 in (0.0254 mm)

Bore diameter Maximum taper Wear limit Maximum ovality Main bearing bore diameter

0.010 in (0.2540 mm) 0.015 in (0.3810 mm) 2.4412 — 2.4420 in (62.006 — 62.026

mm)

Pistons Diameter: Color code red Color code blue Color code yellow

4.0004 — 4.0052 in (101.61 — 101.73 mm) 3.9996 — 4.0002 in (101.58 — 101.60 mm) 4.0020 — 4.0008 in (101.65 — 101.62 mm)

Crankshaft Main bearing diameter Canneacting rad hearing diameter

eee eee eee eet eens .......--e

2.2482 — 2.2490 in (57.10 — 57.12 mm) 2.1228 — 2.1236 in (53.91 — 53.93 mm)

tetas

38

eee

,

UPPER

BODY

FUEL BOWL VENT VALVE

MAIN

BODY ——?>

IDLE ADJUSTMENT SCREW

Fig. 3.7. The three

main

components

of the type 4350 4-V carburetor

ACCELERATOR PUMP ASSEMBLY

THROTTLE LEVER ASSEMBLY

FAST !DLE

Fig. 3.6. General view of the type 2150 2-V carburetor

FAST IDLE SCREW

FAST IDLE LEVER

Fig. 3.8. Fast idle speed adjusting screw (2150 carburetors)

Chapter 3/Carburetion;

52

fuel, exhaust and emission control systems

DIAPHRAGM LINK

THROTTLE

DECEL

MODULATOR

SOLENOID “OFF” IDOLE SPEED ADJUSTING SCREW

FAST IDLE SPEED ADJUSTMENT

Fig. 3.9. TSP adjusting screw (2150 carburetors)

SCREW

FAST !DLE CAM

Fig. 3.10. Fast idle speed adjusting screw (4350 carburetors)

adjust the fast idle adjusting screw to obtain the specified rpm. 9 Set the throttle to the high step of the choke cam and allow the engine to run for 5 seconds (approximately). 10 Rotate the choke cam until the fast idle adjustment screw contacts the choke cam kick-down step. Allow the engine speed to stabilize, then recheck the fast idle rom, as described in paragraphs 8 and 9; readjust if necessary, then repeat the procedure given in the first sentence of the paragraph to ensure repeatability. 11 Allow the engine to return to the normal idle, then for automatic transmission models select Drive. 12 Where no TSP assembly is fitted, adjust the curb idle screw in or out to obtain the specified curb idle speed (photo), then proceed to paragraph

15.

13 Where a TSP assembly is fitted, adjust the curb idle screw which contacts the solenoid plunger to obtain the specified curb idle speed (the solenoid is energized and the plunger extended when the ignition

is ON). 14 Now collapse the solenoid plunger by forcing the throttle linkage against the plunger, grasping the throttle lever and solenoid housing between the thumb and index finger to alleviate movement of the solenoid assembly position. 15 Adjust the TSP-off adjusting screw to obtain the specified TS P-off

Section 10 before commencing. 1 Obtain the best possible idle speed

using the method

given in

Section 13. If the idle speed is unsteady, it should be increased ficiently for the engine to continue running.

suf-

2 Rotate the idle mixture screws within the range of the limiting caps to obtain the most satisfactory idle speed. Where the idle mixture is too rich, indicated by a ‘sooty’ exhaust smoke and engine ‘hunting’ (slowing down and running ‘lumpily’), rotate the screws clockwise. Where the idle mixture is too lean, indicated by the engine speed tending to increase and then decrease, and possibly a ‘hollow’ exhaust note, rotate the screws counter-clockwise.

4 lf the idle mixture cannot be set satisfactorily within the range of the limiting caps, pull off the caps and adjust the mixture screws but refit the caps afterwards. In case it is not possible to obtain a satisfactory setting, rotate each screw in turn, counting the exact number of turns to just seal it, then back off the same number of turns. This will give a datum point from which adjustment can commence. Both screws can be expected to be the same number of turns from the seat when correctly set, after which the limiting cap must be refitted. 5 On completion of any idle mixture adjustment, ensure that the

setting

is checked

by a Ford

dealer

or carburetor/emission

control

specialist at the earliest opportunity.

idle speed, (see Figs. 3.9 and 3.11). 16 Open the throttle slightly to allow the solenoid plunger to extend. 17 Provided that all adjustments are now satisfactory, stop the engine, then install the air cleaner and its associated vacuum lines. If the adjustments are not satisfactory, refer to paragraphs 4 in Section

10. 18 Restart the engine and if necessary run it up to normal operating temperature. With the engine running 2000 rpm (approximately) select Park (automatic transmission) or Neutral (manual transmission). Allow 5 seconds (approximately) for the speed to stabilize, then let the engine return to idle; set automatic transmission models to Drive. Recheck the curb idle speed, and if necessary readjust as described in paragraph 10 onwards. 19 Refit all vacuum lines.

14

15 Carburetor — fast idle cam clearance 1

Remove the air cleaner if the carburetor is installed on the engine.

2 Insert the unmarked shank of a twist drill 0.1 in (2.5 mm) diameter between the lower edge of the choke plate and the air horn wall. Note:

No 38 drill is 0.1015 in; No 39 drill is 0.0995 in. 3 With the fast idle screw held on the bottom step of the fast idle cam, against the top step, the choke lever tang and the fast idle cam arm should just be in contact. Bend the choke lever tang up or down as

necessary.

16

Carburetor — choke plate vacuum

pull-down

1

Remove the air cleaner if the carburetor is installed on the engine.

Carburetor — idle mixture adjustment

Note: Idle mixture adjustment can only be satisfactorily carried out by the artificial enrichment method using special test equipment. The

2 Remove the three screws and the ring retaining the choke thermostatic spring cover. Do not remove the screw retaining the water

procedure given in this Section allows approximate settings to be obtained should this be necessary (eg. after carburetor overhaul). Read

cover. 3

Pull

the

cover

assembly

away

and

remove

the

electric

assist

53

IDOLE SPEED ADJ. SCREW

THROTTLE LEVER

SOLENOID

THROTTLE POSIT!IONER ADJUSTMENT (EITHER END) (TSP ON’ CURB IDLE)

Fig. 3.11. TSP adjusting screw (4350 carburetors) MEASURE

BOTTEM VALVE

HOT

CLEARANCE

EDGE OF CHOKE TO WALL

OF

AIR

HORN

IDLE

COMPENSATOR

Fig. 3.12. Choke plate pull-down clearance (2150 carburetors)

CONNECT HAND VACUUM PUMP

CHOKE PULLDOWN DIAPHRAGM ADJUSTMENT SCREW

DRIEDOR

GAUGE

OF SPECIFIED

SIZE

TAPER-—LOCK

CHOKE

SHAFT SCREW

(LEFT HAND THREAD)

FAST IDLE CAM ADJUSTING

i=

SCREW

0.036 INCH WIRE GAUGE

FAST IDLE ADJUSTMENT

SCREW

&

APPLY LIGHT PRESSURE “*

TO CHOKE

LEVER

Fig. 3.13. Checking the choke plate pull-down clearance (4350 carburetors)

FUEL BOOSTER

VENTURI

BOWL VENT VALVE

SCREW

UPPER

BODY

YOKE CHOKE

PLATE SCREW

YOKE SCREW

(2 REQ’D)

\ METERING RODS

=

IFTR

Or

dp~—

GASKET

CASKET

CHOKE PLATE SUPPORT

eee CHOKE

SPRING ; p

——

CHOKE PLATE ROD

-y

BOOSTER

ASSEMBLY

eae ee aS

PLATE SHAFT

LEVER RETAINING bce

AND

WEIGHT

tna ee |o- \\

TAPE SCALE

CLUTCH PEDAL SS

CLUTCH PEDAL (EREE POSITION) SS

Ss

dD

KOY

FREE TRAVEL FROM

FREE POSITION TO POINT OF INCREASED

S

lane

es

ioe

CENTER OF EITHER SIDE OF CLUTCH PEDAL PAD MEASURE FROM THIS POINT

Fig. 5.4. Checking the clutch pedal free play

PRESSURE

88

Chapter 5/Clutch

CLUTCH STOP

CLUTCH

PEDAL

CLUTCH

ROD AND BELLCRANK

ROD

ADJUSTMENT

POINT

Fig. 5.5. Clutch adjustment point

CLUTCH

EQUALIZER

RETRACTING SPRING

Fig. 5.6. Clutch equalizer shaft and brackets

rivets and the plate for rim distortion, cracks, broken hub springs, and worn splines. The surface of the friction linings may be highly glazed, but as long as the clutch material pattern can be clearly seen this is satisfactory. Compare the amount of lining wear with a new clutch driven plate at the stores in your local repair station, and if the linings are more than three quarters worn renew the driven plate. 2 Check the machined faces of the flywheel and the pressure plate. If either is grooved it should be machined until smooth or renewed. 3 If the pressure plate is cracked or split it is essential that an exchange unit is fitted, also if the pressure of the diaphragm spring is

suspect. 4

Check

the

releace

hearinn

fnr

emoothnece

nf

anneratinn

Thera

should be reasonably 5 Check flywheel is

6

no harshness and no slackness in it. It should spin freely bearing in mind it has been pre-packed with grease.

also that the clutch pilot bearing serviceable, if not, fit a new one.

in the center

of the

Clutch — refitting

1 It is important that no oil or grease gets on the clutch driven plate friction linings, or the pressure plate and flywheel faces. It is advisable to refit the clutch with clean hands and to wipe down the pressure nlata

ana

thinahoal

farac

.mnth.4

clasn.

we

eon

ata

ee ee ee eis

Chapter 5/Clutch

89

Degins. 2 Place the clutch driven plate against the flywheel, ensuring that it is the correct way round. The flywheel side of the clutch driven plate is

marked

on the center (photo). If the driven plate is fitted the wrong

way round, it will be quite impossible to operate the clutch. 3 Place the clutch cover assembly on the flywheel (photo). Refit the bolts and spring washers, and tighten them finger tight so that the clutch driven plate is gripped but can still be moved. 4 The clutch driven plate must now be centralised so that when the engine and gearbox are mated, the gearbox input shaft splines will pass through the splines in the center of the driven plate hub. 5 Centralisation can be carried out quite easily by inserting a round bar or long screwdriver through the hole in the center of the clutch, so that the end of the bar rests in the small hole in the end of the crankshaft containing the input shaft pilot bush. Ideally an input shaft should be used. 6 Using the input shaft pilot bush as a fulcrum, moving the bar sideways or up and down will move the clutch driven plate in whichever direction is necessary to achieve centralisaion. 7 Centralisation is judged by removing the bar and moving the driven plate hub in relation to the hole in the center of the clutch cover diaphragm spring. When the hub appears exactly in the center of the hole all is correct. Alternatively the input shaft will fit the bush and center of the clutch hub exactly, obviating the need for visual align-

poe

ee

IDE |

ment (photo). 8 Tighten the clutch bolts firmly in a diagonal sequence to ensure that the cover plate is pulled down evenly and without distortion of the flange. Finally tighten the bolts down to the specified torque.

9

Refit the clutch housing, using the reverse procedure to removal

as described in Section 3.

7

Clutch release bearing — removal and refitting

1 With the gearbox and engine separated to provide access to the clutch, attention can be given to the release bearing located in the bellhousing, over the input shaft. 2 The release bearing is a relatively inexpensive but important component and unless it is nearly new it is a mistake not to renew it during an overhaul of the clutch. 3 To remove the release lever and bearing first remove the rubber dust cover from the lever aperture in the clutch housing. 4 Slide the release lever inward to release the spring retaining clips from the pivot assembly. 5 To free the bearing from the release arm simply unhook it, and then with the aid of two blocks of wood and a vise, press off the

release bearing from its hub. 6 Refitting is a straightforward reversal of these instructions.

8

Clutch linkage — removal and refitting

1.

The most likely source of wear in the clutch linkage is the equalizer

%&

6.3 Refitting the clutch assembly

shaft bushes. 2 Toremove the shaft, jack up the front of the vehicle and support it on axle stands. 3. Disconnect the clutch release lever retracting spring (Fig.5.6). 4 Remove the spring retainer and washer and detach the clutch release rod from the equalizer shaft. Remove the spring clip and washer from the end of the clutch 5 relay rod and detach the rod from the equalizer shaft. Remove the nuts and bolts securing the equalizer shaft mounting 6 bracket to the side of the chassis member and slide the bracket and shaft assembly off the clutch housing mounting bracket. Remove the bushes from inside the ends of the equalizer shaft and 7 fit new ones. Refit the equalizer shaft and clutch linkage using the reversal of 8 the removal procedure. 9 Finally, adjust the clutch as described in Section 2.

9

Clutch pedal — removal and refitting

From beneath the dash panel remove the spring clip and discon1 nect the operating rod from the clutch pedal lever (Fig. 5.3). Retrieve the bush from the lever.

6.7 Centralizing the clutch driven plate using the gearbox input shaft

90 ee 2

Undo

the locknut

securing

Chapter 5/Clutch eee the clutch

lever to the clutch pedal

required, there are several tests which can be made.

shaft assembly and remove the lever. 3 Remove the shoulder bolt, bush and locknut securing the master cylinder push rod to the brake pedal. 4 Pull the clutch pedal and shaft outwards and remove them together with the brake pedal and bushes.

5 With the engine in second or third gear and pulling lightly, sudden depression of the accelerator pedal may cause the engine to increase its speed without any increase in road speed. Easing off on the accelerator will then give a definite drop in engine speed without the vehicle slowing.

5 Examine the bushes and shaft 6 Grease the shaft and bushes assembly using the reverse of the 7 Finally, adjust the clutch and De

6 In extreme cases of clutch slip the engine will race under normal acceleration conditions. 7 If slip is due to oil or grease on the linings, a cure can sometimes be effected by squirting carbon tetrachloride into the clutch. The permanent cure is, of course, to renew the clutch driven plate and trace and rectify the oil leak.

10

for wear and renew if necessary. and refit the clutch and brake pedal removal procedure. pedal height as described in Section

Fault diagnosis — clutch

There are four main faults to which the clutch and release mechanism are prone. They may occur by themselves, or in conjunction with any of the other faults. They are clutch squeal, slip, spin and judder.

Clutch squeal — diagnosis and remedy 1 If, on taking up the drive or when changing gear, the clutch squeals, this is indicative of a badly worn clutch release bearing. 2 As well as regular wear due to normal use, wear of the clutch release bearing is much accentuated if the clutch is ridden or held down for long periods in gear, with the engine running. To minimise wear of this component the vehicle should always be taken out of gear at traffic lights and for similar hold-ups. 3 The clutch release bearing is not an expensive item, but is difficult

to get at.

Clutch spin — diagnosis and remedy 1 Clutch spin is a condition which occurs when there is an obstruction in the clutch, either in the gearbox input shaft or in the operating lever itself, or oil may have partially burnt off the clutch lining and have

left a resinous deposit which is causing the clutch disc to stick to the pressure plate or flywheel. 2 The reason for clutch spin is that due to any, or a combination of, the faults just listed, the clutch pressure plate is not completely freeing from the driven plate even with the clutch pedal fully depressed. 3. If clutch spin is suspected, the condition can be confirmed by extreme difficulty in engaging first gear from rest, difficulty in changing gear, and sudden take up of the clutch drive at the fully depressed end of the clutch pedal travel as the clutch is released. 4 Check the clutch linkage adjustment (Section 2). 5 If these points are checked and found to be in order then the fault lies internally in the clutch, and will be necessary to remove the clutch for examination.

Clutch slip — diagnosis and remedy 1 Clutch slip is a self-evident condition which occurs when the clutch driven plate is badly worn, oil or grease have got onto the flywheel or pressure plate faces, or the pressure plate itself is faulty. 2 The reason for clutch slip is that due to one of the faults above, there is either insufficient pressure from the pressure plate, or insufficient friction from the driven plate to ensure solid drive. 3 If small amounts of oil get onto the clutch, they will be burnt off under the heat of the clutch engagement, and in the process, gradually darken the linings. Excessive oil on the clutch will burn off leaving a carbon deposit which can cause quite bad slip, or fierceness, spin and judder. 4 If clutch slip is suspected, and confirmation of this condition is

Clutch judder — diagnosis and cure 1 Clutch judder is a self-evident condition which occurs when the gearbox or engine mountings are loose or too flexible, when there is oil on the face of the clutch friction plate, or when the clutch pressure plate has been incorrectly adjusted. 2 The reason for clutch judder is that due to one of the faults just listed, the clutch pressure plate is not freeing smoothly from the driven plate and is snatching. 3 Clutch judder normally occurs when the clutch pedal is released in first or reverse gears, and the whole car shudders as it moves backward or forward.

Chapter 6 Manual and automatic transmissions Contents

Part A: Manual transmission Fault diagnosis — manual transmission .................. Input shaft — dismantling andreassembly ................ Manual transmission — general description ............... Output shaft — dismantling and reassembly ............... Shift linkage — description and adjustment................

20 5 1 6 8

diransmiIssion|—cishiantlingmscess meri eeern mene? eenenna ee Transmission — examination and renovation............... IiranSmiSstoni-=teaSSe Moly seer en nee iiransmisston —iremovalranc retittingiees ntsc ene nena

10 19 ie 16 18

Neutral start switch — removal and refitting ............... Selectonlinkage—adjulstmentsmna suse arene ore ane Transmission tluidilevelicheckincmsnteune tenn naieneitn ann ene ciaeaeeene tatiana ene Tiransmisstoni=removalkandiretittinguac. Transmission shift linkage — removal and refitting...........

3 4 7 2

Part B: Automatic transmission Automatic transmission — general description ............. Fault diagnosis — automatic transmission ................ Intermediate band — adjustment (C4 andC6).............. susie ols tira ean oe Keck-COWMinOG!—.acjUStMent a ceearinmee. Low and reverse band — adjustment (C4 only) .............

Specifications

Manual gearbox 3 forward, 1 reverse

Number of gears MV DCLONGE ALS INT eat aes

cho,

Synchromesh Gearboxatyperdesigqnatlonvanke

Ritapes 8. Rs

heh

case le

sapere a= s see} « aoe

ones

ev leee

hv whats

o iiene es+

Helical, constant mesh

All forward gears 3.03

Gear ratios Zein avAeye 1 tial Salma

Gountengearendfloate. Reverseidlerendiloat: Pubricanttypemenewn

si ai

esis

v5.

es SS

¢ ...i.6 4a: nae bet tes el

eet wert.

Eubricantica pacity

ho, Maer

ht

ohare.

2 az.c5 > wn ea

teen oe

ee

ie

gt

0.004 — 0.018 in (0.10 —0.45 mm)

eet

0.004 — 0.018 in (0.10— 0.45 mm)

vey ty SE ee ican

eee

Ford manual transmission lube (ESW — M2C83 — B)

2 US quarts (1.89 liters)

Automatic transmission C4 (302 cu in engines)

C6 (351 and 460 cu in engines) Bubricanttyoeu

..4..ccerie

et Che te

fubricant-eapacity.(CG) 2 a4).%. Eubricanticapacity;(C4)itarcis

eek tes cae

8s wt

es

es

ieniere unrattan

Shift lever positions bothtypes

ertle eens bern

ee cee

12.25 US quarts (11.57 liters)

one

................2+-555:

10.5 US quarts (9.92 liters) BARING

Ibf ft

Torque wrench settings Manual transmission EHLNWeTe TOWNUIG) Gyevoon Glee. GeBl

Automatic transmission fluid type ESW — M2C33 — F

ob) Ach oh NENG Crit ennai

2

eel

kgf m

SO)

3.4-—4.146

14 15 11 12 13

Chapter 6/Manual and automatic transmission

92

Cover to gearbox case Clutch nousingito gearbox(CaSes ca.) sen aen ween roren i ace t eee Clutch housing to engine Extension housing ta\qeanbOx:CaSen. yar renee ie iene eels FICE EMAC HRA Meco gine San ome core hon ude homo mem mon ox

— 1.94 1.658 5.528 -6.47

12-14 40-47

DD = D7)

5.8-6.9

30-36

4.14-—4.97

23-28 28-40 12-16 12-16 23 — 33 20-30 12-16 20-25 32 —42 55-75 80-120

— 3.870 3.18 3.9-5.5 1.658 —2.211 1.658 —2.211 3.18 -4.6 2.764-4.14 1.658-—2.211 2.77 -3.4 4.4-5.8 7.6-—10.2 11.6 — 16.60

Automatic transmission Converter to flywheel Converter housing to transmissin case Oillsump tomtransmiuSSioniCaSe, eke ceca eek verre rene temas ernie arcs ConvertencovertoiconverterNOuUSING) “42.6. sae e ce ela oer =. FINE OUCIAMNSHOM co cutoonsome oboe cappaoopmogco ode

Converter drain plug (if fitted) Downshift lever to shaft Filler tube to engine FitletatubestO: Summ0Grcnen sc eewrsun nate ers tain sper shisha reton weer ohatredauam enCRN Nel Neutral switch to case Oil cooler line connections

3.04 — 3.7

42-50

Part A: Manual transmission

1.

Manual transmission — general description

The manual transmission fitted as standard to all Econoline models is equipped with three forward gears and one reverse. All forward gears are engaged through synchro-hubs and rings to obtain smooth, silent gearchanges. All forward gears on the mainshaft and input shaft are in constant mesh with their corresponding gears on the countershaft gear cluster and are helically cut to achieve quiet running. The reverse gear has straight-cut gear teeth and drives the first gear through an interposed sliding idler gear. The gears are engaged inside the box by means of two sliding forks. The gears are selected by a steering column mounted shift lever connected by rods and levers to the transmission. Where close tolerances and limits are required during assembly of the transmission, selective thrust washers and snap-rings are used to eliminate excessive endfloat or backlash. This eliminates the need for using matched assemblies.

2

to removal. Note: It may be necessary to rotate the engine to align the clutch disc and input shaft splines.

3

Transmission — dismantling

1

Place the complete unit on a firm bench or table and ensure that

you have the following tools available, in addition to the normal range of wrenches etc.

a)

Transmission — removal and refitting

1 If the transmission alone is to be removed from the vehicle, it can be taken out from below leaving the engine in position. It will mean that a considerable amount of working room is required beneath the vehicle, and ideally ramps or an inspection pit should be used. However, provided that suitable jacks and supports are available, the task can be accomplished without the need for sophisticated equip-

ment. 2 Disconnect the battery ground lead. 3 Remove the lower extension-to-gearbox securing bolt and drain the transmission oil into a suitable container. 4 Disconnect the front of the driveshaft from the rear of the transmission, (see Chapter 7) and tie the shaft out the way. 5 Disconnect the speedometer drive cable from the transmission extension housing. 6 Remove the spring retaining rings and disconnect the two operating rods from the gearshift levers on the side of the transmission. 7 Disconnect the lead from the transmission back-up light switch (if

fitted). 8 Place a jack under the transmission some nylon rope or similar.

9

transmission assembly to the ground. 13 When refitting the transmission, ensure that the clutch release lever and bearing are correctly located in the clutch housing. 14 Apply a smear of light grease on the transmission input shaft splines and then install the transmission using the reverse procedure

and secure it to the jack with

Raise the transmission slightly and remove the four bolts securing

the rear support crossmember

to the chassis side members.

Remove

the bolt securing the extension housing to the crossmember (Fig. 6.1). 10 Lower the transmission assembly just sufficiently to enable the four transmission-to-clutch housing bolts to be removed. 11 Wedge blocks of wood between the bottom of the engine and crossmember to prevent the engine dropping when the transmission is removed. 12 Carefully pull the transmission and supporting jack rearwards until the input shaft is clear of the clutch housing and then lower the

Good quality snap-ring pliers, tracting.

2 pairs — 1 expanding and 7 con-

b)

Copper-headed hammer, at least 2 |b.

c) d)

Selection of steel and brass drifts. Small containers.

e)

Engineer's vise mounted on firm bench.

f)

Selection of steel tubing.

2 Any attempt to dismantle the transmission without the foregoing is not impossible, but will certainly be very difficult and inconvenient. 3 Read the whole of this Section before starting work. 4 Undo the securing screws and remove the cover plate and gasket from the top of the casing. Drain out any oil remaining in the casing. 5 Remove the spring and detent plug from the aperture in the top left-hand side of the casing (see Fig. 6.2). 6 Undo the retaining bolts and withdraw the extension housing from the rear of the casing (see Fig. 6.3). Remove the gasket. 7 Undo the retaining bolts and remove the bearing retainer and gasket from the front of the casing. 8 Remove the oil filler plug from the side of the casing. Using a suitably sized drift through the plug aperture, drive out the roll pin that secures the countershaft to the casing (see Fig. 6.4). 9 Using a soft alloy drift, carefully tap the countershaft out of the rear of the casing, while supporting the countershaft gear cluster with one hand. 10 When the shaft is removed, lower the countershaft gear cluster and thrust washers to the bottom of the casing. 11 Remove the snap-ring securing the speedometer drivegear to the output (rear) shaft. Slide the gear off the end of the shaft and remove the gear locking ball from the shaft. 12 Remove the snap-ring securing the rear bearing to the output bearing and, using two screwdrivers, placed between the outer snap-

ring and casing, carefully lever the bearing out of the casing and slide it off the end of the output shaft. Note: If difficulty is experienced in removing the bearing a special tool

(No. T63P-7025-A) is available from your Ford dealer (Fig. 6.5). 13

Place the two shift levers on the side of the casing in the neutral

(center) position.

93 CROSSMEMBER POSITION FOR MANUAL TRANSMISSION SHOWN (USE LONG SLOTS) REVERSE POSITION OF CROSSMEMBER FOR AUTOMATIC

TRANSMISSION

(USE SHORT

Can

SLOTS)

SCREW

MACHINED

INSULATOR AND RETAINER ASSEMBLY

SPRING «

ef

2ND

INTERLOCK

SURFACE AND

3RD

SHIFT

EXPANSION

ae PLUG

FORK PLUG

fss LOCKWASHER

DETENT

®

SPRING

PLUG BOLT

1ST AND REVERSE SHIFT FORK 2ND AND 3RD SHIFT RAIL

Fig.

6.1.

Transmission

crossmember

support

and

1ST

AND SHIFT

REVERSE RAIL

Fig. 6.2. Gear shift selector forks and rails

(COUNTERSHAFT ie ROLL PIN |

FRONT BEARING RETAINER

~=GASKET——>

GASKET COUNTERSHAFT GEAR

ran

-y) plu”

Fig. 6.4.

Driving the roll pin out of the countershaft

Fig. 6.3. Gearbox case and associated components

Clamp

Block

SNAP

RING GROOVE

Tool—T63P-7025-A

Remover

————— a

Clamp

Block

:

Pesae

on Remever

{; SNAP

RING

|fe J

Fig. 6.5. Using the special tool to remove and replace the output shaft bearing

Chapter 6/Manual and automatic transmission

94

SHAFT ANDLEVER

EOGK>

WASHER

Q-

NUT

Fig. 6.7. Removing the shift levers

Fig. 6.6. Turning the 2nd/3rd gear shift rail thru 90° INPUT SHAFT

FRONT

SNAP RINGS

L

ROLLER

AND GEAR

BEARING

BLOCKING

BEARINGS

RING

Fig. 6.8. Input shaft and bearings

SNAP

THRUST

RING

WASHER 1ST

|SYNCHRONIZER

SNAP

RING REAR

GEAR f OUTPUT

SHAFT

BEARING \

SNAP

RINGS

OcC BLOCKING RINGS

SNAP 2ND

RING

LOCK

BLOCKING RING

SPEEDOMETER

DRIVE REVERSE

GEAR

BALL

GEAR

AND

se GEAR

SLEEVE

Fig. 6.9. Exploded view of the output shaft assembly