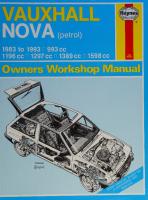

Haynes Vauxhall Chevette Owners Workshop Manual 0856962856, 9780856962851

“148 p. : 28 cm Distributed in the U.S. by Haynes Publications, Los Angeles Includes index”.

138 8

English Pages 160 Year 1976

Recommend Papers

- Author / Uploaded

- John H. Haynes

- P. G. Strasman

- Similar Topics

- Technique

- Transportation: Cars, motorcycles

File loading please wait...

Citation preview

a ee e B a t e eee ty Neneetn eens

Se

Sree as ahi ees

=

;

ae

;

Se

aye

as

st re

Poe

ae

:=

SoS

atest

Paine

:

= =

f Sate

a ees

:

ier

ae

ienaeelataeee

ss aes See

=e

5

A

ni Sen

ioe.ent

ae

75. Suit. 1984

Ss

WITHDRAW

|. ANCASHIRE LIEZARIEs | MONTHLY LOAN NOMLIGHIX2 LOAN FROM Z |

AUTHOR

HAYes,

saved by avoiding the costs a garage must charge to cover its labour and overheads. The book has drawings and descriptions to show the function of the *rious Components so that their layout can be understood. Then the *«s are described and photographed in a step-by-step sequence so that ~/en a novice can cope with complicated work. The jobs are described assuming only normal tools are available, and not special tools unless absolutely necessary. However, a reasonable outfit of tools will be a worthwhile investment. Many special workshop tools produced by the makers merely speed the work, and in these cases guidance is given as to how to do the job without them. On a very few occasions, the manufacturer's special tool is essential to prevent damage to components, then its use is described. Though it might be possible to borrow the tool, such’ Work may have to be entrusted to the official agent.

To avoid labour costs a garage will often give a cheaper repair by fitting a reconditioned assembly. The home mechanic can be helped by this book to diagnose the fault and make a repair using only a minor spare part.

The manufacturer's official workshop manuals are written for their trained staff, and so assume special knowledge; therefore detail is left out. This book is written for the owner, and so goes into detail.

Using the manual The manual is divided into twelve Chapters. Each Chapter is divided into numbered Sections which are headed in bold type between horizontal lines. Each Section consists of serially numbered paragraphs.

There are two types of illustration: (1) Figures which are numbered according to Chapter and sequence of occurrence in that Chapter. (2) photographs which have a reference number on their caption. All photographs apply to the Chapter in which they occur so that the reference figure pinpoints the pertinent Section and paragraph number. Procedures, once described in the text, are not normally repeated. If it is necessary to refer to another Chapter the reference will be given in Chapter number and Section number thus: Chapter 1/16. If it is considered necessary to refer to a particular paragraph in another Chapter the reference is given as Chapter, Section and Paragraph number eg; Chaptet 1/5:5). Cross references given without

use of the word ‘Chapter’ apply to Section and/or paragraphs in the same Chapter (eg; ‘see Section 8’ means also ‘in this Chapter’). When the left or right side of the car is mentioned it is as if one is seated in the driver’s seat looking forward. It should be noted that apart from the engine and gearbox (unified threads) all of the fixings in the Chevette are metric. Whilst every care is taken to ensure that the information in this manual is correct, no liability can be accepted by the authors or publishers for loss, damage or injury caused by any errors in, or omissions from, the information given.

Contents Chapter

Section

Introductory sections

Buying spare parts Routine maintenance

1

Removal Dismantling Examination

2

3

4

Engine

Cooling system

Carburation; fuel and exhaust systems

Ignition system

Page 5 6

21 27 28

Draining/flushing/filling Antifreeze mixture Radiator

30 31 31

Thermostat Water pump Fan belt

31 33 34

Air cleaner Fuel pump Fuel tank

35 37 37

Choke and accelerator controls Carburettor Manifolds and exhaust system

39 41 44

Contact breaker points Condenser

47 AT

Ignition timing Coil

48 49

Distributor

48

Spark plugs

50

and renovation

Adjustment Cable renewal Pedal

53 53 53

6

Gearbox

Removal

56

8

9

Rear axle

Braking system

10 Electrical system

I

8 9

Reassembly Installation Adjustment after overhaul

Clutch

Propeller shaft

Lubrication chart Dimensions, weights and capacities

Page

15 17 18

5

7

Section

and installation

Removal, inspection and renovation Release bearing ~~ Refitting clutch

Countershaft servicing

54 54 55

62

Dismantling

59

Reverse pinion and gear casing

62

Mainshaft servicing Input shaft servicing

59 62

Reassembly Extension housing rear oil seal

63 65

Universal joints — testing for wear

66

Propeller shaft — removal and installation

67

Axleshafts (halfshafts)

68

Rear axle —

Pinion oil seal renewal

71

removal and installation

Disc pads Rear brake shoes Disc caliper Brake disc Operating (slave) cylinders

74 +~ Master cylinder 75 ~~ Flexible hoses ~=Bleeding 76 : ~Handbrake 77 ~+Vacuum servo unit 77

Battery Alternator Starter motor Fuses

Switches 85 87 —_ Lights Windscreen wiper 89 Wiring diagrams , 92 __..

73

78 81 81 81 82 93 98 101 108

121 Steering 115 Front suspension 126 Wheels and tyres 119 Rear suspension a ————————————————————————————— N ——— N ———————A ——— 139 ~=—‘Ta ilgate 127 Mai nte nan ce fitt and ings Bod 12 ywork 139 Bonnet 127. Repairs 142 Heat er 133 Doors 11 Suspension and steering

Each Chapter contains ‘Specifications’, ‘General description’ and ‘Fault diagnosis’ as applicable Metric conversion tables Index

Vauxhall Chevette L

Vauxhall Chevette GL

Introduction to the Vauxhall Chevette The Chevette is a three door ‘Hatchback’ saloon, sharing many components with the Opel Kadettg and the other GM ‘T’ cars. The engine is the same as that used in the smaller capacity Vivas. General mechanical layout of the Chevette is conventional. Four models are available at present: standard, ‘E’, ‘L’ and ‘GL’ — the latter having more luxurious trim and additional accessories and the

‘E' being a low priced economy model. The Vauxhall Chevette has been well received by the motoring public, and is obviously a well designed car. Together with its pleasing the Chevette offers excellent performance and fuel performance economy and a very practical Saloon cum Estate capability.

s r e b m u n n o i t a c i f i t n e d i e l c i h e v & s t r a p e Ordering spar Vehicle identification numbers

Buying spare parts Spare part$ are available from many sources, for example: Vauxhall garages, Other garages and accessory shops, and motor factors. Our advice regarding spare parts is as follows: Officially appointed Vauxhall garages - This is the best source of parts which are peculiar to your car and otherwise not generally available (eg; complete cylinder heads, internal gearbox components, ld shou you h whic at e plac only the also is It . etc) trim rior inte es, badg s ent pon com all uxh -Va non : anty warr r unde still is car your if s part buy may invalidate the warranty. To be sure of obtaining the correct parts it and ne engi s car' your eman stor the give to y ssar nece be ys alwa will tive posi for g alon part old the take to , ible poss if and , ber chassis num ory fact a on e labl avai are s part y man that er emb Rem identification. It n! clea be ys alwa ld shou rned retu s part any exchange scheme car your on sts iali spec the to ight stra go to e sens d goo es mak y ousl obvi you. ly supp to ed ipp equ best are they for part of type for this ces pla d goo y ver en oft are se The ps sho ory ess acc and s age Other gar r you of ce nan nte mai the for ded nee ts en on mp to buy material and co up chtou , ase gre and oils ts, bel fan bs, bul gs, plu rk spa s, car (eg; oil filter e hav y all usu es, ori ess acc l era gen sell o als y The ). etc paint, filler paste nd fou be en oft can and ces pri er low rge cha rs, hou convenient opening not far from home. t an rt po im re mo the of all ck sto l wil s tor fac od Go Motor factors , ts en on mp co tch clu ; (eg y ckl qui y vel ati rel out components which wear s oe sh s/ al se s/ se ho s/ pe pi s/ er nd li cy ke bra s, tem sys t us ha ex pistons, valves,

and pads etc). Motor components

amount

on

a part

Modifications are a continuing and unpublished process in vehicle manufacture quite apart from major model changes. Spare parts manuals and lists are compiled upon a numerical basis, the individual to correct identification of the being essential vehicle numbers component required. When ordering spare parts, always give as much information as possible. Quote the car model, year of manufacture, body and engine numbers, as appropriate. The car identification plate is fitted on the upper surface of the instrument panel and is legible through the windscreen. A second identification plate is affixed to the side of the engine compartment and bears the following information: Model Market Job no. Paint code Trim code Option code

d ne io it nd co re or w ne e vid pro en oft l wil s factor exchange

basis - this can

save

a considerable

of money.

Car identification plate located on instrument panel

t ke ac br or at rn te al to nt ce ja ad er Location of engine numb bey

Under bonnet identification plate

|

Routine maintenance Maintenance is essential for ensuring safety and desirable for the purpose of getting the best in terms of performance and economy from the car. Over the years the need for periodic lubrication - oiling, greasing and so on - has been drastically reduced if not totally eliminated. This has unfortunately tended to lead some owners to think that because no such action is required the items either no longer exist or will last for ever. This is a serious delusion. It follows therefore that the largest initial element of maintenance is visual examination. This may lead to repairs or renewals.

In the summary

given here the ‘essential for safety’ items are shown

in bold type. These must be attended to at the regular frequencies shown in order to avoid the possibility of accidents and loss of life. Other neglect, results in unreliability, increased running costs, more rapid wear and more rapid depreciation of the vehicle in general.

SE ee ee ee Every 250 miles (400 km) travelled or weekly

a

Steering Check the tyre pressures, including the spare wheel. Examine tyres for wear or damage. Is steering smooth and accurate?

Brakes Check reservoir fluid level. Is there any fall off in braking efficiency? Try an emergency stop. Is adjustment necessary?

Lights, wipers and horns Do all bulbs work Are the headlamp ne ee Do the wipers and Check windscreen

at the front and rear? beams aligned properly? horns work? washer fluid level.

Engine Check the sump oil level and top-up if required. Check the radiator coolant level and top-up if required. Check the battery electrolyte level and top-up to the level of the plates with distilled water as needed.

Topping up the engine oil

Location and marking of engine oil dipstick

Routine maintenance

7

Every 6000 miles (9600 km) or at six monthly intervals

Check front hub bearing adjustment. Check disc pads and brake shoes for friction material wear. Adjust clutch free-travel Change engine oil and renew oil filter element. Check and if necessary, top-up gearbox oil level. Check and if necessary, top-up rear axle oil level. Check brake hydraulic system for leaks, damaged pipes etc. Examine thickness of tyre treads. Check and adjust, if necessary, front wheel alignment. Examine exhaust system for corrosion and leakage. Lubricate all controls and linkages. Check for wear in steering gear and balljoints and condition rubber bellows, dust excluders and flexible coupling. Clean and adjust spark plugs. Clean and adjust contact breaker points and lubricate. Top-up carburettor damper. Lubricate door locks and hinges.

of

Every 12000 miles (19300 km) or annually Inspect condition of wiper blades and renew if necessary. Inspect security of seat belts and anchorages. Check antifreeze strength and top-up if necessary. Clean corrosion from battery terminals and apply petroleum jelly. Check fanbelt tension and adjust if necessary. Renew spark plugs. Renew contact breaker points and check ignition timing. Clean fuel pump filter. Clean crankcase breather valve hose. Adjust valve clearances. Renew air cleaner element.

Every 24000 miles (38600 km) or at two yearly intervals Dismantle, clean and relubricate front hub bearings.

Check and adjust if necessary the headlamp alignment. 'nspect and

if necessary,

renew

any suspension

bushes which

have

deteriorated or worn. Check torque of all suspension bolts and nuts e. ur xt mi ze ee fr ti an th wi em st sy g in ol co ill ref d Drain, flush an

Every 48000 miles (77000 km) Bleed brake hydraulic system check and if necessary, renew

of old fluid, renew all rubber seals, any damaged pipes and refill system

with clean fluid. t. en id ev if t af sh w ne re d an ar we r fo ts Check propeller shaft join w ne y pl ap d an n ea cl d an n io os rr co or st ru r fo Check underbody protective sealant where necessary.

Distributor lubrication points 7 2 3

Felt pad Baseplate hole Cam lubricator

(grease only)

Jacking points be y ma r ca e th th wi ed li pp su ck ja e When changing a roadwheel, th e th w lo be d te ca lo e ar h ic wh ts in po g in used, inserting it into the jack ck ja a e us t, ou d ie rr ca g in be e ar s ir pa re or bodysills. Where maintenance

ng si ca le ax ar re e th or r be em located either under the front crossm th wi ck ja e th nt me le pp su ys wa al r, tubes. Before getting under the ca s. er mb me e am fr dy bo e th r de un ed on ti axle stands or blocks posi

;

ae

,

| rae

w=

=

Recommended

tl

lubricants and fluids

Component

Engine (1)

:

Castrol Product

a

Gearbox (2) _ ...

cele tL EA ae ns

aes

Se

be

Castrol GTX

Fe

ste

¥

ca

ae

$s.

es

Castrol Hypoy (90 EP)

a ...

Wes ...

ta a

a fe

ie nee

ee ..

Castrol Hypoy (90 EP) Castrol LM Grease

sees ss 0s sss se

we ws ae

Ses Castrol LM Grease Ss =~ Castrol Castrolite ee Castrol Girling Universal Brake and Clutch Fluid

Distributor spindle and advance mechanism (8)

if

Distributor cam (9) Chassis (general) aes

che

Rear axle (3) * an Front wheel bearings (4)

Steering gear (5) 0s, Carburettor damper (6). Brake master cylinder (7) ...

wee aye hor

Hinges, locks, pivots, etc...

see

Castrol GTX

ee a

ee oe

ae ee es:

Castrol LM Grease or Vaseline Castrol LM Grease

ne

one

“i:

Castrol GTX or Everyman

Note: the above are general recommendations. vehicle usage. Consult the operators handbook * Where an axle has to be topped-up or drained gears are fitted, use only the special lubricant

ove

Lubrication requirements vary from territory-to-territory and also depend on supplied with your car. and refilled before completing 10,000 miles (16,000 km), or when new hypoid supplied by your Vauxhall dealer.

General

s e i t i c a p a C & s t h g i e W , s n o i s n e Dim

Overall length ...

155.3 in (3944.0 mm)

Overall width

...

62.2 in (1580.0 mm)

Overall height ...

51.9 in (1317.0 mm)

Wheelbase

94.2 in (2392.0 mm)

Track (front and rear)

51.2 in (1300.0 mm)

Kerb weight

1951 |b (855 kg)

Maximum payload

810 Ib (397 kg)

Engine (oil capacity)

5.5 Imp. pints (3.13 litres)

Gearbox (oil capacity)

0.9 Imp. pint (0.51 litres)

Rear axle (oil capacity)

1.2 Imp. pints (0.68 litres)

Cooling system (coolant capacity)

10.2 imp. pints (5.80 litres)

Fuel tank (capacity) ...

8.0 Imp. galls (36.4 litres)

Chapter 1 Engine Contents

Ancillary components - installation Ancillary components - removal ; Camshaft and tappets -examination and renovation. Camshaft and tappets - installation Camshaft and tappets - removal Crankcase ventilation system : Crankshaft and main bearings- examination and renovation Crankshaft and main bearings - installation Crankshaft and main bearings - renewal Z Cylinder block and crankcase -examination and fenoveton Cylinder head- decarbonising, valve grinding and renovation Cylinder head - dismantling Cylinder head - reassembly and installation Cylinder head - removal

Engine Engine Engine Engine Engine Engine

-

dismantling general tes adjustment after major overhaul installation complete with gearbox installation without gearbox ... reassembly general removal without gearbox

...

Engine - separation from gearbox

Engine/gearbox - removal

;

Examination and renovation- general Fault diagnosis -engine : Flywheel - examination and renOVECION! General description Major operations only possible alter removal ‘of engine fro) car Major operations possible with engine in car

Methods of engine removal Oil pump and oil filter - removal Oil pump - examination and renovation Oil pump and sump - refitting ... Piston/connecting rod- refitting Piston/connecting rod - removal Piston/connecting rod assemblies - examination ana renovation er Sa Sump - removal ... Timing components - refitting.. Timing cover, gears and chain - renoval Timing gears and chain -examination and renovation

S S S S

Specifications —_—_—_eeree—e—————eeeeee

ee

eee

Engine general Type Displacement Bore

2a

e

2 4 ey

>

te

7 + ©

31.1 Using a valve grinding suction tool to install 2 tappet

31.3 Correct installation of camshaft thrust plate

Fig. 1.12 Reassembling timing chain tensioner (Sec. 32) 1

Sleeve

2

Spring

3

Piston

="

23

Chapter 1/Engine compound and then install the rear bearing cap, the correct way round (photo). Ensure that any shims are refitted in their original positions under the main bearing caps. Note the bolt on the centre main bearing cap to which the oil pump pick-up pipe is attached. 8 Fit the front and centre main bearing caps (the correct way round) complete with their shells and then insert and tighten all main bearing

cap bolts to the specified torque (photo). 9 Check the crankshaft endfloat using a dial gauge or feeler blades. This should be as specified in Specifications, provided the centre flanged shell bearings are to manufacturer's specified tolerance.

the crankshaft

10 Turn

and check that it rotates smoothly

during a

achieve this (photo). 6 Install the camshaft sprocket bolt and tighten to the specified torque. 7 Depress and then release the pad of the chain tensioner. This will disengage the internal pip and enable the tensioner to take up its operational tension. 8 Remove the timing cover oil seal and drive in a new one, using a piece of tubing as a drift. Apply engine oil to the seal lips and then install the timing cover, using a new gasket. Tighten the bolts only finger-tight at this stage. 9 Install the crankshaft pulley and tighten its securing bolt to the

specified torque (photo).

complete revolution.

10 Finally tighten the timing cover bolts to the specified torque.

30 Piston/connecting rod - refitting 1 The assemblies will have been prepared as described in Sections 22 and 23. 2 Apply engine oil liberally to the cylinder bores and to the piston rings. 3 Fit a piston ring compressor to no. 1 piston and then insert the connecting rod into the cylinder bore nearest the front of the block. Check that the notch in the piston crown faces the front of the engine

(photo). 4 With the piston skirt having entered the cylinder bore and the compressor resting squarely on the block, place the wooden handle of a hammer on the centre of the piston crown and then tap the head of the

_ handle sharply to drive the piston assembly into the bore. 5 With the crankpin at its lowest point, carefully pull the connecting rod downward and connect it to the crankshaft. Make sure that the big-end bearing shell has not become displaced. ng ki ma ll, she g in ar be th wi e et pl om (c p ca g in ar be 6 Install the big-end d an t en nm ig al in are p ca d an d ro e th on s rk ma ng hi tc sure that the ma ed id ov pr c, ti ma to au be l wil is Th . ne gi en e th of e sid t ec are on the corr e th d an d le mb se as y tl ec rr co en be ve ha d ro the piston and connecting . ed on ti si po y tl ec rr co is n ow cr on st pi e th on h tc no ue rq to d ie if ec sp e th to n te gh ti d an s lt bo d 7 Screw in the big-en

(photo).

. the

8 Repeat assemblies.

operations

foregoing

on

remaining

the

three

33 Oil pump and sump - refitting 1 Rotate the crankshaft by means of the pulley bolt until the pointer on the crankshaft pulley is opposite the TDC mark on the timing cover, with no. 1 piston on the compression stroke. This can be established by

checking

that

nos.

1 and 2 tappets

(counting

from

the front of the

engine) are resting on the lowest profile of the camshaft lobes. (Fig. 1.18) 2 Turn the oil pump drive gear until the drive spindle slot takes up the position shown in the diagram. (Fig. 1.19) 3 Install the oil pump to the crankcase, using a new flange gasket. Make sure that with the oil pump bolts inserted finger-tight, engagets men seg ll sma and e larg the sed cau has r gea vedri ft sha cam the ment of on iti pos the up e tak to ve) abo m fro wed vie en (wh e ndl spi e driv the of

shown.

(Fig. 1.20)

adjust the oil pump

If not, withdraw

the pump

and by trial-and-error,

gears until the correct setting is achieved

(photo).

piston

yo Pit-

—————

a

31 Camshaft and tappets - installation ~ — — — — — — E E — — — — — — — — ——E I in em th l tal ins d an cks blo pet tap the oil ed, ert inv ne gi 1 With the en

their original sequence (photo). the om fr ft ha ms ca the ert ins lly efu car and gs rin 2 Oil the camshaft bea front of the cylinder block (photo).

te pla the t tha e sur ng ki ma ts, bol ng uri sec and te pla ust 3 Install the thr ner sio ten in cha t res nea k for r nge (lo n ow sh as is exactly positioned

in cha ing tim the of g tin fit t rec cor it rm pe to er slipper) (photo), in ord |

tensioner.

5 .0 (0 in. 9 00 0. d an 2 90 0. n ee tw be be ld ou sh at lo 4 The camshaft endf If e. ug ga l dia a or es ad bl ler fee th wi . ted tes be n ca and 0.23 mm) which te. pla st ru th e th w ne re d, ie if ec sp at th s ed ce ex the endfloat

i

32 Timing components - refitting S e T G y il ar or mp te et ck ro sp h it (w ft ha ms ca 1 Rotate the crankshaft and the fitted)

drawn

until

the

between

timing

marks

the centres

are adjacent

to each

of the crankshaft

other

and a line

and camshaft will pass

through them.

’ ‘2 ng ri sp e th l al st in t rs fi , ed tl 2 f the chain tensioner has been disman ge ga En . ly mb se as d pa e th of ’ ‘1 (Fig. 1.12) and piston ‘3’ in the sleeve ss re mp co w No . on st pi e th in ve oo gr e th th wi ve ee sl e th de si in p pi e th e th of d en e th at ss ce re e th in s ge ga en p pi e th l ti un ts en on mp co e th d. te ac tr re in ma re w no ll wi on st pi e Th . piston groove . dy bo r ne io ns te e th in ly mb se as d 3 Install the retracted pa e th on ng ti un mo le zz no l oi e th to ly mb se as r ne io ns te e th 4 Install front face of the block. en th d an et ck ro sp ft ha ks an cr e th 5 Engage the timing chain with engage the install the are marks

w No n. ai ch e th of op lo r pe up e th in camshaft sprocket with ng mi ti e th at th so n ai ch th wi te le mp camshaft sprocket co of nt ou am n ai rt ce A 1. in paragraph as described

ft ha ms ca d an n ai ch e th of g in on ti reposi

sprocket

will be required to

Pek

sah oak

s rk ma et ck ro sp of t en nm ig al g in 32.5 Timing chain components show

Fig. 1.14. Engine timing marks (Sec. 33) 32.9 Installing crankshaft pulley

7

Crankshaft pulley pointer

2

Timing cover TDC mark

1,e «4 Fig. 1.15. Oil pump drive spindle set ready for installation (Sec. 33) Fig. 1.16. Alignment of oil pump drive spindle (viewed from above)

after correct installation. A to B is permitted tolerance (Sec. 33)

33.3 Installing oil pump

Fig. 1.17. Sealing sump gasket at rear bearing cap (Sec. 33)

25

Chapter 1/Engine 4 Tighten the oil pump bolts to the specified torque. 5 Reconnect the pick-up tube support to the securing bolt located on the centre main bearing cap. the an cle t firs s, thi do To . led tal ins be now uld sho s ket gas p 6 The sum l sea cap g rin bea r rea the o als , ase nkc cra and mp su of es mating fac groove. 7 Apply suitable jointing compound to the corners formed by the rear main bearing cap seal groove and the crankcase. Install the sump gasket so that the ends of the gasket are located in the cap groove and then apply more jointing compound to seal the ends of the gasket within the

groove (photo). the rear seal and shape it to fit the groove in the bearing cap.

8

Warm

9

Install the seal so that the chamfers

‘A’ (Fig. 1.18)

face inwards.

Apply jointing compound to the junctions of the seal and gasket and then install the sump, tightening the bolts in diagonally opposite sequence. Do not overtighten them. 10 Note the gearbox to sump bracket brace. The inclusion of the

lockwasher ‘3’ is essential (Fig. 1.19).

34 Cylinder head - reassembly and installation 1 Install the valves in their original sequence or if new ones have been purchased, to the seats to which they have been ground. 2 Fit new valve stem oil seals and circlips to the four inlet valve guides. oil ine eng d lie app ing hav t firs de, gui its o int ve val t firs the 3 Insert

liberally to its stem (photo). 4 Fit the valve spring, the retaining cap and then compress the valve . stem e valv the of out cutthe in ets coll split the te loca spring and Release the compressor. Repeat these operations on the remaining

seven valves (photo). 5 When all the valves have been installed, place the cylinder head flat , tor ula ins an as od wo of ck blo a and er mm ha a ng usi on the bench and tap the end of each valve stem to settle the components. 6 Install the rocker balls (photo). 7 Install the rocker springs so that the smaller coil is nearer the cylinder head. 8 Install the rockers and the self-locking nuts, only screwing on the nuts a few turns.

33.7 Fitting sump gasket

) 33 . ec (S e ac br mp su to x bo ar ge Fig. 1.19. Components of the 1 2

Gearbox brace Sump bracket

3

Lockwasher

34.3 Installing a valve

26

Chapter 1/Engine

=

34.6 Rocker components

4

34.9 Installing cylinder head gasket

oro %D ©)

Fig. 1.21. Cylinder head bolt tightening sequence diagram (Sec. 34)

a a mi “ “I

‘ uel

.

ak

ae

34.12 Checking and adjusting a valve clearance

35.3 Installing the oil filter

9 Make sure that the faces of the cylinder head and the cylinder block are perfectly clean and then lay a new gasket on the cylinder block so that the word ‘Front’ is visible from above and correctly located. Do not use any kind of jointing compound (photo). 10 Lower the cylinder head into position, insert the cylinder head bolts and tighten them in Fig. 1.21.

to the specified torque

and in the sequence

shown,

11 Each rocker can now be swivelled aside and the respective pushrod

installed. Apply engine oil to all the rocker components (photo). 12 The valve clearances should be as described in Section 38, but at approximate clearances so that the this, apply a ring spanner to the crankshaft until no. 1 piston is at established by placing a finger compression can be felt, continue pointer is opposite the TDC mark

set with the engine running and hot, this stage they should be adjusted to engine can be started and run. To do crankshaft pulley bolt and turn the TDC (top-dead-centre). This can be over no. 1 plug hole and when turning until the crankshaft pulley on the timing cover. Insert an 0.008

in. (0.20 mm) feeler blade between the end of no. 1 valve stem and the rocker and adjust the rocker self-locking nut until the feeler blade is a

35.4 Installing the flywheel

stiff sliding fit. Repeat the operation (without moving the crankshaft) on no. 2 valve. The clearances for both inlet and exhaust valves are the

same (photo). 13 Turn the crankshaft until no. 3 piston is at TDC and repeat the adjustment procedure on valves 5 and 6 (counting from the front of the

engine). 14 Turn the crankshaft until no. 4 piston is at TDC and repeat the adjustment procedure on valves 7 and 8. 15 Turn the crankshaft until no. 2 piston is at TDC and repeat the adjustment procedure on valves 3 and 4. If the foregoing sequence of adjustment is followed, it will prevent the crankshaft from being

rotated unnecessarily as the engine firing order is 1-3-4-2.

35 Ancillary components - installation

1 This is a reversal of the removal sequence given in Section 9, of this Chapter. 2 Full details of component installation are given in the relevant

Chapter 1/Engine Chapters of this manual, but the following points should be noted. 3 Always install a new oil filter sealing ring in the cylinder block groove. Tighten the centre-bolt only to specified torque (photo). 4 When installing the flywheel bolts, smear their threads sparingly with a suitable sealer. Excessive amounts of sealer may damage the crankshaft oil seal. Tighten the flywheel bolts to the specified torque

27

Chapter 5. 2 Tighten the clutch bellhousing bolts to the specified torque. 3 Reverse all the operations described in Section 5 of this Chapter, making quite sure that the assembly of the engine front and rear mountings is as illustrated in Figs. 1.23 and 1.24.

(photo). 5

Adjust the fanbelt as described in Chapter 2, Section 12.

36 Engine - installation without gearbox 1 This is a reversal of the removal operations described of this Chapter, but check the following points:

in Section 7,

in bed cri des as ed, lis tra cen n bee has te pla ven dri tch clu the (i) That Chapter 5. as d le mb se as tly rec cor are s ng ti un mo nt fro ne gi (ii) That the en ine eng the in ts bol ger lon use r ve Ne 3. 1.2 shown in Fig. the l fou y ma y the or y, all gin ori ed us se tho n tha ts bol mounting

crankshaft (photo).

37 Engine - installation complete with gearbox

s E — — — — — — — E — E — — II — I 1 Connect the engine and gearbox. This is quite straightforward in bed cri des as ed, lis tra cen n bee has te pla ven dri provided the clutch

and 36 cs. (Se ng ti un mo nt fro ine eng an of w vie ed od pl Ex Fig. 1,23. 37)

i)

1

Tang for location in hole (2)

e th to d ie pl ap er al se th wi lt bo g in in ta re Fig. 1.22. Inserting a flywheel threads to prevent oil seepage from the crankcase (Sec. 35)

) 37 c. (Se ng ti un mo r rea ox rb ea /g ne gi en e th of ew Fig. 1.24. Exploded vi

36.1 Right-hand (cast type) engine mounting

1 2 3

Retaining clip ve ha ts en on mp co me so , de si nd ha tgh ri on ed Hole (to be position arrow to indicate front of crossmember) Bolt

28 ee

ee

Chapter 1/Engine ee et Mele Se ee

Oe MN ee

4 Refill the cooling system with antifreeze Proportions given in Chapter 2. 5 Refill the engine with oil. 6 Check and top-up the gearbox oil level.

mixture,

to

the

38 Engine - adjustment after major overhaul

1 With the engine refitted to the vehicle, give a final visual check to see that everything has been reconnected and that no loose rags or tools have been left within the engine compartment. 2

Turn

the engine

slow

running

screw

in about

% turn

(to increase

slow running once the engine is started) (Chapter 3). This faster slowrunning

will

be

needed

due

to

the

tightness

of

the

new

engine

components. 3 Pull the choke fully out and start the engine. This may take a little longer than usual as the fuel pump and carburettor bowl will be empty and need initial priming. 4 As soon as the engine starts, push the choke in until the engine runs at a fast tickover and examine the engine for leaks. Check particularly

Ve

the water hoses and oil filter and fuel hose unions. 5 Run the vehicle on the road until normal operating temperature is reached. 6 Check and re-adjust the valve clearances by the following method: switch off the engine, disconnect the breather hose from the rocker cover, the coil cover, plug leads, distributor cap and slacken the bolt which holds numbers 3 and 4 spark plug leads to the support bracket. Unscrew the rocker cover screws and lift off the cover. 7 Reconnect the ignition components and start the engine. Unscrew the throttle stop screw until the engine runs as slowly as possible.

8

Insert a feeler blade

(0.008 in/O.20 mm)

between each valve stem

and its rocker in turn and adjust the rocker nut until the feeler can be withdrawn with a stiff pull. 9 Adjust the throttle speed screw to give normal idling speed and then switch off the ignition and refit the rocker cover. 10 Where new internal components have been installed, the engine

speed should be restricted for the first 500 miles (800 km) and at this mileage, the engine oil should be renewed, the cylinder head bolts checked for correct torque (unscrew each bolt one % turn and then tighten to specified torque and in recommended sequence). Finally, check and adjust the valve clearances.

39 Fault diagnosis - engine -—_—_—_—

ne

eee

ee eee

Symptom —_—eererererereeeeeee

ee

Reason Cn

eee

Engine fails to start

eeeee

Discharged battery

Loose battery connection Disconnected or broken ignition leads Moisture on spark plugs, distributor or leads Incorrect contact points gap, cracked distributor cap or rotor Incorrect spark plug gap ; Dirt or water in carburettor jets

Empty fuel tank Faulty fuel pump Faulty starter motor Faulty carburettor choke mechanism Engine idles erratically

Air leak at intake manifold Leaking cylinder head gasket Worn timing sprockets Worn camshaft lobes

Overheating Faulty fuel pump

Engine ‘misses’ at idling speed

Incorrect spark plug gap Uneven compression between cylinders Faulty coil or condenser Faulty contact points Poor connections or condition of ignition leads Dirt in carburettor jets Incorrectly adjusted carburettor Worn distributor cam

Air leak at carburettor flange gasket Faulty ignition advance mechanism Sticking valves Incorrect valve clearance Low cylinder compression Engine ‘misses’ throughout speed range

Dirt or water in carburettor or fuel lines Incorrect ignition timing Contact points incorrectly gapped Worn distributor Faulty coil or condenser Spark plug gaps incorrect Weak valve spring

Overheating

29

Chapter 1/Engine

ee i 1 ) P | Symptom

__

Reason

t e

Engine stalls

Engine lacks power

Incorrectly adjusted carburettor Dirt or water in fuel Ignition system incorrectly adjusted Sticking choke mechanism ed pp ga y tl ec rr co in or s ug pl k ar sp Faulty Faulty coil or condenser Incorrect contact points gap Exhaust system clogged Distributor advance inoperative Air leak at intake manifold ge an fl ng ti un mo r to et ur rb ca at ak Air le Incorrect valve clearance Sticking valve Overheating Low compression em st sy on ti ni ig on s on ti ec nn co Poor electrical

Incorrect ignition timing Faulty coil or condenser Worn distributor Dirt in carburettor d e p p a g y tl ec rr co in s ug Spark pl r to et ur rb ca ed st ju ad y tl ec Incorr Faulty fuel pump

Weak valve springs Sticking valve Incorrect valve timing Incorrect valve adjustment

et sk ga ad he er nd li cy n w o l B Low compression

Brakes dragging Clutch slipping Overheating

Chapter 2 Cooling system Contents

Antifreeze mixture Cooling system - draining Cooling system- flushing

Cooling system- filling..

es

Cooling system- general description

nt

wet

ue

a

at

5 2 3

oe

ae

=H

oe

Pci

ae!

ate

23;

ely

AE

‘ep

we

Ue

Fan assembly- testing, removal and refitting Fan belt - renewal and adjustment

é

Fault diagnosis -cooling system ei aa ae Radiator pressure cap Radiator - removal, inspection, cand and renting:

He

Thermostat - removal, testing and eis

Water pump- overhaul

...

Ae)

s

rena A

RS! 1 6

ae

oe

i

eS}

cs

at

atk

y

We

Water pump - removal and installation

g)

12

—_—_—_—_—_—_—_—_—_—n—n—

Specifications —_—_—_——_——————————————————

eee

System type

Thermo syphon belt driven pump, pressurized

Radiator cap pressure

13 Ib sq in

Thermostat opens

190°F (88°C)

System capacity

10.2 pints (5.80 litres)

Torque wrench settings

Ib/ft 14 24

Fan securing screw Water pump bolts

1

Cooling system - general description

The cooling system is of pressurized type and includes a front mounted radiator, a belt-driven water pump and a viscous-coupling type fan. A thermostat is located in the outlet side of the water pump. The radiator is not provided with a drain plug but one is installed on the right-hand side of the cylinder block. The principle of the system is that cold water in the bottom of the radiator circulates upwards through the lower radiator hose to the water pump, where the pump impeller pushes the water round the cylinder block and head through the various cast-in passages to cool the cylinder bores, combustion surfaces and valve seats. When sufficient heat has been absorbed by the cooling water, and the engine has reached an efficient working temperature, the water moves from the cylinder head past the now open thermostat into the top radiator hose and into the radiator header tank. The water then travels down the radiator tubes when it is rapidly cooled by the in-rush of air when the vehicle is in forward motion. A five-bladed fan, mounted on the water pump pulley, assists this cooling action. The water, now cooled, reaches the bottom of the radiator and the cycle is repeated. When the engine is cold the thermostat remains closed until the

coolant reaches a pre-determined temperature (see Specifications). This assists rapid warming-up. Water temperature is measured

by an electro-sensitive capsule located immediately below the thermostat housing. Water from the engine cooling system is used to provide warmth to the car interior

through the medium of a heater assembly (see Chapter 12).

Nm 19 33

reached. Wait a minute or two with the cap in this position to allow the Pressure in the system to escape. Continue turning the cap fully anticlockwise and remove it. 2 If the coolant is to be retained for further use, place a suitable container under the radiator and then disconnect the bottom hose.

3 Place a second container under the engine and remove the drain plug from the right-hand side of the cylinder block.

eT 3 Cooling system - flushing Ce ee 1 The radiator and waterways in the engine after some time may become restricted or even blocked with scale or sediment which reduce the efficiency of the cooling system. When this condition occurs or the coolant appears rusty or dark in colour the system should be flushed. In severe cases reverse flushing may be required as described later. 2 With the bottom radiator hose still disconnected and the cylinder block drain plug removed, move the heater control lever to the red position. 3 Insert a hose in the radiator filler neck and allow water to run through the system until it flows from both outlets quite clear in colour. Do not flush a hot engine with cold water. 4 In severe cases of contamination of the coolant, reverse flush the system. To do this, remove the radiator, as described in Section 6, invert it and insert a hose in the bottom water outlet. Continue flushing until clear water comes freely from the top tank. 5 The use of chemical cleaners should only be used as a last resort and

the regular renewal of the antifreeze mixture should obviate the need for flushing or other cleaning treatment. ———————————

ae

RN SS

ES

Ee

ee

2 Cooling system - draining ————————E—— ES—— eS ——ee ——e — ee 1 It is preferable to drain the cooling system when the engine has cooled, If this is not possible, then place a cloth over the radiator cap and turn it slowly in ar anticlockwise direction until the first stop is

4

Cooling system - filling Reconnect the radiator bottom hose. Tighten the cylinder block drain plug. Place the heater control lever to the red position.

Pour RWN

coolant (of the specified antifreeze mixture - see next Section)

31

Chapter 2/Cooling system radiator

the

into

filler neck.

Pour

and

slowly

level

the

when

stop

reaches 1 in. (25.0 mm) below the base of the filler neck. 5 \f after operating the car, the heater fails to warm up, then there is be cleared

probably an airlock in the system and it must following way. 6 Disconnect the upper end of the hose which

deteriorated. 9 Installation is a reversal of removal.

in the 7

runs

Radiator pressure can

the

between

cylinder head and the heater control valve. Make sure that the radiator cap is in position, the heater control set to ‘HOT’ and the engine off. 7 Hold the hose upright and using a funnel, pour coolant into the hose until it flows from the control valve. 8 Reconnect the hose to the control valve, run the engine and then check and top-up the coolant level in the radiator.

1 If escaping pressure can be heard from the top of the radiator or if the coolant level requires constant topping-up, it can be assumed that the pressure cap is at fault, provided of course that there are no other leaks in the system. 2 The radiator cap can be tested at most garages and if it is found to be faulty, replaced with one of similar rating (13 Ib sq in. - 0.91 kg sq

cm). 5

Antifreeze mixture 8

1 The coolant should be renewed every two years not only to maintain the antifreeze properties, but also to prevent corrosion in the in s tor ibi inh the of th eng str the as ur occ ise erw oth system which would the coolant becomes progressively less effective. ns tio nec con e hos all ck che , tem sys the to e eez ifr ant ing add 2 Before and check the tightness of the cylinder head bolts as such solutions are h wit ed ill ref tly par and d ine dra be uld sho tem sys searching. The cooling e. eez ifr ant ing add ore bef , ned lai exp y usl vio pre clean water as of els lev s iou var for d use be uld sho h ic wh e eez ifr ant of 3 The quantity protection

Thermostat - removal, testing and refitting

1 A faulty thermostat can cause overheating or slow engine warm up. It will also affect the performance of the heater. 2 Drain off enough coolant through the radiator drain tap so that the coolant level is below the thermostat housing joint face. A good indication that the correct level has been reached is when the cooling tubes are exposed when viewed through the radiator filler cap.

the of ge ta en rc pe a as d se es pr ex w, lo be le tab is given in the

system capacity. Safe pump circulation —12°C ( 10°F) 3°F) —169C( —20°C (— 4°F)

Protection to

Antifreeze volume 25% 30% 35%

—26°C (—15°F) —33°C (—28°F) —39°C (—38°F)

any on uti sol e eez ifr ant an ns tai con em st sy 4 Where the cooling r ila sim in up de ma on uti sol a h wit topping-up should be done on. uti dil id avo to er ord in al gin ori the to s on ti or op pr R E E S EI REIEE EIEEI EEE UU U TE

6

g in tt fi re d an ng ni ea cl , on ti ec sp in l, va mo re or at Radi

1 2

2. n io ct Se in d be ri sc de as , em st sy g in ol co e Drain th e th d an pe pi nk ta er ad he or at di ra e th om fr Disconnect the top hose

e — — EE — I— II A AA — e — Q

overflow tube from the reservoir (if fitted). . pe pi et tl ou or at di ra e th om fr se ho om tt 3 Disconnect the bo 4

Unscrew

and

remove

the

six

retaining

bolts

which

secure

the

). to ho (p ! ne pa ng ti un mo t en tm ar mp co ne gi radiator to the front en Do . ns fi g in ol co e th ge ma da to t no 5 Lift out the radiator, taking care not

allow

antifreeze

solution

to

drop

onto

the

bodywork

during

removal as damage may result. be y ma s ak le r no mi t bu st li ia ec sp a to 6 Radiator repair is best left tackled with a proprietary product. ft so a th wi ng hi us br by s ie fl of d re ea cl 7 The radiator matrix may be brush or by hosing. ee gr de s it to g in rd co ac 3 n io ct Se 8 Flush the radiator as described in ve ha h ic wh s ip cl or s se ho y an w of contamination. Examine and rene

or at di ra e th of ew vi l na io ct Se 3. 2. Fig.

cap (Sec. 7) s lt bo g n i r u c e s or at di ra of n 6.4 Locatio

m o r f ck lo r ai g n i v o m e R Fig. 2.1.

cooling system (Sec. 4)

(one side)

1 2

Pressure valve Vacuum valve

1/0g aysey

dung Bulanzas 1/09 (6u0}/) Bulseag/1 AjquiassefeysS .eIsOUJaY] Buisnoy 4anO7

JIUWIC1ID 8IEJIIJUNOD Bulsds yoo)Bul 6uls /@aS sse Ajquia Aaljnd Bulnunow abuely 19Se5) (140ys) 1/0q dwing Bulsnzas

1a1e duind

Bulinz1/0 asq

4BYSEMYIOT

43//aAUU]

Aal/Nd

JOYSEMYIOT uey BusisinyIOS a zas Puey-349/) (peasyi 4JOYSE// JOYSEMYIOT

Aal|Ndg

| lejsowsay SNOISIA uel

uey/duind Ajquiasse *29S)

1/aq aalig

sazeng

INN

(OL

‘B14 ‘“p'z

MasIS

32

HAMTPTOONDHDOHN

33

Chapter 2/Cooling system E E the aw dr th wi and ts bol ing ain ret o tw the ve mo re 3 Unscrew and d ve mo re be to at st mo er th the it rm pe to tly ien fic suf thermostat cover from its seat in the cylinder head. a by at st mo er th e th d en sp su e, bl ea ic rv se is it un 4 To test whether the e th s, il bo r te wa e th en Wh . ed at he g in be r te piece of string in a pan of wa

thermostat

valve

should

open

% in. (12.5 mm). When

the valve has

. ed os cl ly te le mp co is it at th re su ke ma cooled, d an et sk ga ge an fl w ne a e us t bu l va mo 5 Refitting is a reversal of re e th ce on t in po t es gh hi e th at is n pi le gg ji check that the thermostat

g. in us ho e th in ed at se is at st mo er th i

on ti la al st in d an l va mo re p m u p r te Wa

9

[i t. el nb fa e th ct ne on sc di d an em st sy g 1 Drain the coolin ve mo re d an lt bo un d an mp pu r te wa 2 Disconnect the hoses from the e th ve mo re to ed ne no is e er Th the pump/fan assembly as a unit. ns fi e th ge ma da to t no n ke ta is re ca radiator for this operation provided

11 Fan assembly - testing, removal and refitting 1 This is of viscous type and is a sealed unit. At certain upper engine speeds, the fan ‘free-whee!s’ so saving engine power when the ram effect of cooling air due to the forward motion of the car, is adequate. 2 In the event of overheating, first check the drivebelt tension (see next Section). Operation of the fan viscous coupling can be observed by watching it while the engine speed is increased progressively beyond 1000 rev/min. As the engine speed increases so the speed of the fan blades should decrease. oil e ibl vis or g nin run l coo ly ive ess exc e lud inc ld 3 Any fault which cou leaks, will necessitate renewal of the complete fan unit. the ng vi mo re st fir er aft le sib pos y onl is t uni 4 Removal of the fan a h wit e typ ket soc of is ew scr ng uri sec fan the t tha radiator. Note left-hand thread.

(photo).

ng ti ma e th at th re su ke ma t bu l va mo 3. Installation is a reversal of re to s lt bo ng ri cu se e th n te gh ti d an et sk ga t in jo w ne a e us n, ea cl e ar faces n io ct Se in d be ri sc de as t, el nb fa e th st ju ad d an t fi Re . ue rq to t ec rr the co

12: i

EEE EEE

EERE

10 Water pump - overhaul ee ee is it at th ty ul fa s e m o c e b p m u p e th n e h w at th d e d n e m m o c e r is 1 \t r Fo . it d un e n o i t i d n o c e r a or t n e n o p m o c w e n a h t i w er th ei d e w e n e r g n i w o l l o f e th t ou y fr ca , y l b m e s s a al in ig or e th ir pa re to h s i w o those wh operations. r te wa e th om fr ey ll pu e iv dr d an n fa s ou sc vi e th e v o m e r d an 2 Unbolt . ad re th d an -h ft le a s ha w re sc ng ri cu se n fa e th at th te No pump flange. t. af sh e th m o r f er ll pe im e th w a r d h t i w , er ll pu d e g g e l o w t a 3 Using . y d o b p m u p e th m o r f e c a f r e t n u o c c i m a r e c d n a al se e th t 4 €xtrac e th s es pr n e h t d n a it g n i z e e u q s y b ng ri g n i k c o l ng ri sp 5 Release the p m u p e th m o r f , ge an fl ey ll pu h t i w e t e l p m o c , y l b m e s s a shaft/bearing body. to in it s es Pr . y l b m e s s a an as d e w e n e r is y l b m e s s a 6 The shaft/bearing e th d n a t rs fi s r e t n e t af sh e th of d n e r e t r o h s e th at th so the pump body e th in e v o o r g g n i k c o l e th h t i w ns ig al t n o r f e h t m o second groove fr . ng ri g n i k c o l g n i r p s e h t l body. Instal d n a s e v o o r g e th h t i w e g a g n e s p i p e th at th so al se 7 Assemble the e th to d e i l p p a e b y a m e s a e r g le tt li A . y d o b p m u p install it to the g. in tt fi te ta li ci fa to al outside edge of the se s d r a w o t is e c a f r e b b u r e h t t a h t so e c a f r e t n u o c 8 Install the ceramic the impeller. , t f a h s e h t o t n o d e s s e r p e b t s u m e g n a l f y e l l u p e h Q The impeller and t . d e n i a t t a e ar 8 . 2 g. Fi in n w o h 50 that the dimensions s

) 10 . ec (S ng ri g in ck lo ng ri sp mp pu r te wa g in as Fig. 2.5. Rele

) d e w o r r a ( e v o o r g ng ri g n i k c o l g n i r a e b / t f a h s p m u p r e t a W Fig. 2.6.

(Sec. 10)

y l b m e s s a p m u p r e 9.2 Removing wat ) 10 . ec (S al se p m u p r te wa e th of ns io ct se o w t e h T 7. 2. Fig.

34

Chapter 2/Cooling system

Fig. 2.8. Sectional view of the water pump showing setting of pulley

A

=

mounting flange and impeller (Sec. 10) B = 0.044 to 0.046 in. 3.46in. (88.0 mm) (7.12 to 1.17 mm)

Fig. 2.10. Point at which to test drivebelt deflection (Sec. 12) alternator away from the engine until the slack is taken out of the belt. Tighten (but do not fully tighten) the bolts in the following sequence:

12 Fanbelt - renewal and adjustment 1 the 2 the fan 3

To renew the drivebelt, slacken the alternator mounting bolts and adjustment strap bolts. Push the alternator in towards the engine and then slip the belt from alternator pulley, finally withdrawing it from the crankshaft and pulleys. Installation is a reversal of removal.

4

Whenever

Maintenance

a

belt

is fitted

or

at

regular

intervals

(see

Routine

Section), adjust the belt in the following way.

Pull the

(i) front mounting, (ii) adjustment strap bolt, (iii) rear mounting. 5 Test the belt deflection (% in./6.0 mm) with the thumb as shown (Fig. 2.10). If necessary adjust the position of the alternator on its mountings until the tension is correct and then fully tighten the alternator bolts in the sequence previously described and finally tighten the bolt which secures the adjustment strap to the engine. 6 If a lever is being used to move the alternator away from the engine,

always make sure that the bolts are released first and that the lever is applied only to the alternator drive end shield.

13 Fault diagnosis - cooling system Symptom

Reason

Overheating

Low coolant level Faulty radiator pressure cap

Thermostat stuck shut Drive belt slipping or incorrectly tensioned Clogged radiator matrix

Incorrect engine timing Corroded system

Cool running

Incorrect type thermostat

Faulty fan viscous coupling Slow warm up

Thermostat stuck open

Coolant loss

Faulty radiator pressure cap Split hose Leaking water pump to block Joint Leaking core plug Blown cylinder head gasket

m e t s y s l e u F 3 r e Chapt Contents

on ate ie se se sti ss r aes

. .. nt me st ju ad d an g in tl an sm di l ro nt co r to Accelera rae aes .. g. in st te d an n io pt ri sc de r ne Air clea om Ps on ... l wa ne re t en em Air cleaner el ne .. l. ve le oil g in in ta in ma er mp da Carburettor sas ... _ ly mb se as re d an g in tl an sm di r to et ur rb Ca of ... g in tt se t ar st ld co d an e idl Carburettor - fast ae s ale bes n io pt ri sc de l ra ne ge Carburettor iss ee nt me st ju ad d ee sp ng Carburettor - idli se we on ti la al st in d an Carburettor - removal

ss ae Carburettor vent valve - adjustment... ne Choke control cable - removal and refitting ... sus Fault diagnosis - fuel system and carburation Fuel pump - description, testing and cleaning a aed Fuel pump - removal and installation ... See Fuel tank - removal, servicing and installation Fuel tank transmitter unit - removal and installation ae at iad we aT General description ak ess Manifolds and exhaust system - general

9 ee 2 se 3 ies dc anne LS ae AZ fav AD ie il Aree alo

a ae ses

aw a we

ais

ner

as

J

ae er

wes PAL

_

ds Specifications

n i ( o. n j Fuel pump

Mechanical

Pressure ...

2% to 3% Ib/sq. in

Carburettor

Stromberg

3 Type Identification:

3696B 3698 BIDV 2.54 mm M2

Standard compression engine Low compression engine Metering needle Jet orifice

As Bey

ass Fast idle cam Inlet needle valve...

150CD—SEV

1.5mm 1.6 mm 800 to 850 rev/min

) ss ne ck hi (t er sh wa e lv va Inlet Idling speed

Fuel tank

) s e r t i l 4 . 6 3 ( . s 8 Imp. gall

Capacity Fuel octane rating: ne gi en n io ss re mp co rd Standa Low compression engine

97 90 Ib/ft

Torque wrench settings Fuel pump bolts Inlet manifold bolts ExPraust manifold bolts Carburettor flange bolts

Nm

20

28

25

35

28 24

39 33

EE 1 General description E E pe w lo be ed at oc (l nk ta el fu d te un mo ar re a s se ri mp co em st The fuel sy ft ha ms ca a , l) ne pa r oo fl nd ha tgh ri t en tm ar mp co ng yi rr the load ca

r. to et ur rb ca g er mb ro St a d an p m operated tuel pu a es at or rp co in d an pe ty ed ll ro nt co eur at er mp te of is r ne The air clea disposable paper element.

2 2

g n i t s e t d n a n o i t p i r c s e d Air cleaner

i e e r h t s e s i r p m o c r e n a e l c air 1 The

temperature

sensing

unit,

(ii) a vacuum

major

components:

capsule,

(i)

a

(iii) an exhaust

manifold shroud. t n e m t r a p m o c e n i g n e at r e n a e l c r ai e h t to in n w a r 2 Cold air is d e h t m o r f e s o h le ib ex fl a h g u o r h t n w a r d is r ai t o h e temperature whil s. lt bo r u o f y b d e r u c e s is h c i h w , d u o r h s d l o f i n a m t s u exha

3

The vacuum

capsule

is connected

to a control damper

assembly

2) . ec (S s lt bo g n i r u c e s d u o r Fig. 3.1. Exhaust manifold sh

= et) LS 4 5 6 7 1 f

36

oe ) Fig. 3.2. Air cleaner assembly (Sec. 2) 7

Temperature sensor

2

Vacuum capsule

3

Exhaust manifold shroud

Fig. 3.3. Levering off the air cleaner sensor unit (Sec. 2)

5.3 Removing the fuel pump

Fig. 3.4. Installing the air filter element (Sec. 3)

37

Chapter 3/Carburation; fuel and exhaust systems which regulates the intake of hot and cold air to provide air of even and optimum temperature for the carburettor. 4 When the engine is running, the degree of vacuum in the capsule is dependent upon the temperature sensor unit. This is of bi-metal spring s run ich (wh line uum vac the into air ed ble to ns ope construction and the er nev whe e) sul cap uum vac the to ld ifo man ake int the m fro

. °C) (40 °F 104 ve abo s rise r ane cle air the hin wit re atu per tem air il unt sed clo be l wil t por air d col the , ine eng d col a 5 When starting sor sen the e uat act to gh ou en rm wa is ud ro sh t drawn from the exhaus unit. 6 A fault in the operation of one or more of the components of the der col in but r, the wea rm wa in nt are app be air cleaner may not to cy den ten l era gen a and ng lli sta or ts spo t conditions, surging, fla weakness may be noticed. the ew vi to ror mir a use r, ane cle air the of n io at er op 7 To check the the If ut. spo ake int r ane cle air the h ug ro th attitude of the damper

n see be l wil t por ake int air d col the C) 3° engine is cold (below 90°F/3

s thi e ov ab are es ur at er mp te r ane cle air and ine to be closed. If the eng the om fr ion iat dev any is re the If n. ope be level, the cold air port will the and g din bin for e kag lin the k ec ch , ons iti correct damper pos sor sen the of n io at er op the t tes n the and ty connecting hoses for securi and er cov r ane cle air the ve mo re d, col ine eng unit. To do this, have the of ce pie a ng usi t uni sor sen the to nt install a thermometer adjace the as n soo as and ine eng the rt Sta er. cov the e adhesive tape. Replac er cov r ane cle air the ve mo re t, por air d col the damper is seen to open F 5° 11 and 90 n ee tw be te ica ind uld sho s Thi and read the thermometer. w ne re ge, ran s thi hin wit en op not (33 and 47°C). If the damper does p. cli ing ain ret its off ng eri lev by t uni the sensor N SEE EEE EEUU e e

1

renewed. Earlier renewal dusty conditions.

may

6

of removal, but use new sealing gaskets on insulator which was originally fitted. Make goes above the camshaft eccentric before and tightening to the specified torque.

Fuel tank - removal, servicing and installation

1 Remove the left-hand side panel from the load carrying area. This is secured by five press studs and a lever will have to be inserted between the trim and body panels to release them. 2 Remove the right-hand trim panel in a similar manner and then extract the upper securing screw from the fuel tank filler pipe protective shroud.

3 Remove the floor panels, noting integral with the right-hand panel.

that

the

filler pipe shroud

oe cS

EERE

3 Air cleaner element - renewal ne

Every 12000 miles (19000 km)

4 Installation is a reversal the flange and replace any sure that the rocker arm installing the securing bolts

6) . ec (S s ip cl l ne pa im tr or ri te in dy Bo 6. Fig. 3.

the air cleaner element should be

be required

if the car is operated in very

r. ne ea cl air e th om fr se ho er th ea br e as kc an cr 2 Disconnect the r. ne ea cl air e th om fr pe pi ke ta in air t ho 3 Disconnect the flexible on d te ca lo is h ic wh e ul ps ca um cu va e th 4 Disconnect the hose from the underside of the air cleaner. . ws re sc ng ri cu se six e th ng wi re sc un r te af 5 Remove the top cover air e th of or ri te in e th n ea Cl it. d ar sc di 6 Lift out the element and cleaner body. ke ma t bu l, va mo re of al rs ve re a is t en em 7 Installation of the new el . om tt bo e th at is t en em el e th of ng ri g in al sure that the rubber se ea

4

EEE aE

ng ni ea cl d an g in st te n, io pt ri sc de Fuel pump

emcee

pee

d an e as kc an cr e th of de si d an -h ft le e th on d te ca lo is p m u p el fu e 1 Th on c ri nt ce ec an th wi t ac nt co in is h ic wh m ar er ck ro a y b ed at er op it is the camshaft. e th ng ni ea cl om fr t ar ap d an on ti uc tr ns co ed al se of is p m u p e 2 Th in d an le ib ss po is g in tl an sm di no s, al rv te in d e d n e m m o c e r at en re sc filter p m u p e th , ng pi lo ve de t ul fa a of t en the ev

must be renewed complete.

om fr pe pi el fu e th ct ne on sc di , mp pu e th of n io at er op e th st te To 3 t rs fi — g in av (h r te ar st e th on ne gi en e th in Sp r. to carburet the d an ) ng ri fi ne gi en e th t en ev pr to il co e th om fr ad le LT e th ed disconnect en op e th om fr d te ec ej e ar el fu of ts ur sp d ne fi de ll we r he observe whet y. tl ec rr co g in at er op is p m u p e th en th e, ar ey th If . pe pi e th of end 4

To

clean

the filter,

first disconnect

the fuel

inlet pipe from

the

at th d e d n e m m o c e r is It . el fu of ss lo t n e v e r p to e p i p e th pump and plug e r o f e b , le ib ss po as w o l as t p e k is k n a t e th in el fu the level of . n o i t a r e p o g in ic rv se is th commencing r, ve co e th y a w a ft li d an w re sc re nt ce r ve co p m u p e th 5 Unscrew sealing ring and gauze filter. . e l b m e s s a e r d n a or ri te in p m u p d n a e z u a g e th m o r f 6 Brush any dirt t s u m e s e h T . gs pe ur fo s e t a r o p r o c n i e z u a g er lt fi e th On some pumps, . w e r c s e r t n e c r e v o c e th n e t h g i t r e v o t no o D r. ve co p o t face towards the Cee

SSE

5 Fuel pumppose eau 1 2 3

eee

ee

eee

removal and installation

. el fu of ss lo t en ev pr to it ug pl d an pe pi t le in el fu e th ct ne on sc Di . mp pu e th om fr pe pi et tl ou e} fu e th Disconnect

p m u p e th ft li d an s lt bo ng ri cu se p m u p o tw e th ve mo re d an w Unscre

from the crankcase (photo).

6) . ec (S s on ti ec nn co d an nk ta Fig. 3.8. The fuel

is

Chapter 3/Carburation; fuel and exhaust systems

38

h oug thr e pip er fill the ing lat ipu man e tim e sam the at on, ati loc from its its body sealing grommet.

8 A leak in a fuel tank should be repaired by specialists or a new tank fitted. Never be tempted to solder or weld a leaking fuel tank. 9 If the tank is contaminated with sediment or water, it can be swilled out using several changes of fuel, but if any vigorous shaking is required to dislodge accumulations of dirt, then the tank transmitter unit should first be removed, as described in the next Section. 10 Installation of the fuel tank is a reversal of removal.

Fig. 3.9. Fuel tank transmitter unit correctly installed (Sec. 7)

Fig. 3.10. Choke control attachment to steering column shroud (Sec. 8)

4 Disconnect fuel in the tank 5 Disconnect 6 Disconnect

7

the fuel outlet pipe (no drain plug is fitted) and let the drain into a suitable container. the fuel tank vent pipe. the lead from the fuel level transmitter unit.

Unscrew and remove the four tank securing bolts and lift the tank

Fig. 3.11. Accelerator control detail (RHD cars) (Sec. 9)

Chapter 3/Carburation; fuel and exhaust systems

39

vw

7

Fuel tank transmitter unit - removal and installation

1 Carry out the operations given in paragraphs 1 to 6 of the preceding Section. 2 Unscrew and remove the five securing bolts and withdraw the unit carefully, so that the float mechanism is not damaged. 3 Installation is a reversal of removal, but always use a new flange . nd ou mp co ng nti joi h wit es sid h bot on d are sme gasket which has been is It ts. bol ng uri sec the of s ead thr the to nd ou mp co ng nti joi Also apply is er itt nsm tra the on al min ter the , led tal ins n essential that whe . car the of e sid and t-h lef the s ard tow ng nti poi and horizontal

choke remains fully off even flexible mountings.

9

under extreme

engine movement

on its

Accelerator control - dismantling and adjustment

1 The pendant type accelerator three screws. After removal of cable assembly can be dismantled 2 After reassembly, or if the

pedal is secured to the fascia panel by these screws, the composite rod and for renewal of any worn component. cable has stretched and pedal free-

movement has become excessive, carry out the following adjustment procedure. 3. Disconnect one end of the linkage rod which runs between the pedal and the cable relay levers. the th Wi ). 13 3. g. (Fi ‘2’ op st er bb ru the t ns 4 Position the lever ‘1’ agai

R R E EE EEEE EEEE EE E UEEE e e

8

g in tt fi re d an l va mo re e bl ca l ro nt co e Chok

Ce

n aw dr th wi be n ca ob kn d an e bl ca r ne in control 1 The choke e ok ch r to et ur rb ca e th om fr e bl ca e th g in completely after disconnect Operating lever. h ic wh ng ri g in ck lo e th d, ve mo re be to ve ha 2 Should the outer cable to ve ha ll wi ud ro sh mn lu co ng ri ee st e th secures it to the lower half of to ed us be n ca rs ie pl d se no dun ro in th be unscrewed. For this, a pair of . ng ri g in ck lo e th in s le ho o tw e th engage in r ne in e th ng ti ec nn co re fo be t bu l va 3 Refitting is a reversal of remo en op y ll fu is e at pl e lv va e ok ch e th cable to the carburettor, check that 8 1/ t ou ab it aw dr th wi en th d an y ll fu ob and then depress the choke kn e th at th re su en to k ac sl gh ou en st ju e in. (3.2 mm). This will provid

e bl ca e th ate , rot on ti si po ed os cl ly ful e th in er lev le tt ro r th to et ur rb ca e th off ck ba en th d an e bl ca e th om fr d ve mo re is ck sla locknuts until all t ke ac br t or pp su the to on ti si po s thi in it k loc d an s rn tu 1% t upper nu with the lower nut. or ett bur car the on er lev le ott thr the m Ja s: car 5 On right-hand drive

and 5) 3.1 g. (Fi ‘1’ t bol p am cl the n cke Sla in the fully open position. rd, boa toe the om fr ) mm .0 (10 in. 0 0.4 d hel al ped or rat ele acc the h wit

retighten the clamp bolt. in r to et ur rb ca e th on r ve le le tt ro th e th m Ja 6 On left-hand drive cars: en th d an ’ ‘3 el iv sw e th om fr ‘1’ ip cl the fully open position. Detach the l da pe e th ld Ho ). 17 3. . ig (F ’ ‘2 r ve le l da pe e th om fr el iv sw e th ve mo re or up el iv sw e th w re sc en th d an d ar bo e 0.20 in. (5.0 mm) from the to

e th th wi t en nm ig al t ec rf pe in is el iv sw e th l ti un down the threaded rod . ip cl e th t fi Re r. ve le l da pe e th hole in

9) . ec (S ) rs ca D H L ( il ta de l ro Fig. 3.12. Accelerator cont

Fig. 3.17. Accelerator clip (1) pedai lever (2) and swivel (3) (LHD cars) (Sec. 9)

THROTTLE STOP

SCREW

Fig. 3.15. Accelerator rod clamp

bolt (1) and position rod (2) (RHD

carl (Gee, 9)

eee

=

hy

4

Fig. 3.18. Location of threttie step serew (Sec. 1)

Chapter 3/Carburation; fuel and exhaust systems

10 Carburettor - general description 1 The carburettor is a Stromberg 150CD-SEV, constant vacuum type and incorporates a variable jet which is controlled by an air valve piston and metering needle. The latter is spring-loaded against one side of the jet, to ensure a consistent fuel flow. 2 The carburettor has a manually-operated disc type cold starting device. 3 A temperature compensator is incorporated to offset variations in mixture strength caused by heat transfer from the engine to the carburettor body. 4

The carburettor

to

the

idle

bleed

is pre-set and any adjustment

screw

trimming

should

(see Section

be restricted

11). Only

if the

carburettor has been dismantled and reassembled, will re-setting of the jet adjuster be required, as described in Section 16.

11 Carburettor - idling speed adjustment should

The throttle stop screw

1

speed

is between

800

and

accurately set by connecting

850

be adjusted until the engine idling

rpm.

Obviously,

a tachometer

this can

only

be

to the engine, but normally

this can be judged fairly well. Do not permit teo low an idling speed. a e vid pro to htly slig wed cre uns is ew scr m tri idle the , cars 2 On new slightly weak mixture. Should the idling become uneven, turn the trim . seat its into d har it ew scr t oun acc no On . ise ckw clo tly gen ew scr not is it re Whe s. ion rat ope t men ust adj of it lim the is ing ego 3 The for et inl the in ks lea air for k loo , ing idl oth smo e iev possible to ach e. hos er ath bre ase nkc cra and es pip um cu va the manifold gasket,

12 Carburettor - fast idle and cold start setting

m ca e idl t fas the n, aw dr th wi ly ful is ob kn l! tro con e ok 1 When the ch ter fas a to er lev le ott thr the en op and ate rot l wil or on the carburett than normal setting. uld sho ew scr p sto the , ied cif spe as is ed spe e idl t fas the t tha er 2 In ord in. 0 0.1 is ‘A’ n io ns me di t tha so ) off ly ful e ok ch be adjusted (with the (2.5 mm) as shown in Fig. 3.20.

e ur xt mi rt sta ld co the t tha re su en to ed id ov 3 A spring-loaded pin is pr

is correct

for various

climatic

Where

conditions.

the temperature

is

ve oo gr e th to es gl an tgh ri at set be ld ou sh n above O°F (—18°C) the pi in n pi the set el, lev s thi w lo be e is ur at er mp te the e er ‘3’ (Fig. 3.21). Wh

its of re su es pr e th t ns ai ag it s es pr de st fir its groove. To turn the pin,

spring.

Fig. 3.21. Cold start device (Sec. 12) 1

13 Carburettor damper - maintaining oil level

Spring-loaded stop

2

Pin

3

Groove

c li au dr hy e th ve mo re d an w re sc un ), km 0 1 Every 6000 miles (960 damper from the top of the carburettor. r to et ur rb ca e th se rai d an 3) on ti ec (S t en em el r ne ea 2 Remove the air cl . ake int air e th o int er ng fi a g in rt se in by on air valve pist if up pto d an d ro e id gu ow ll ho e th in oil 3 Check the level of the ) mm 0 (8. in. 30 0. is el lev e th il unt oil ne gi en 30 necessary with 10W/ below the top of the guide rod. t tha e sur ke ma t bu l va mo re of r de or e th g in rs ve 4 Reassemble by re re fo be d ro e id gu ow ll ho e th rs te en d ro er mp the small collar on the da screwing the damper cap down.

14 Carburettor vent valve - adjustment De to ly al rn te in ed nt ve e ar r be am ch t oa fl 1 Fumes from the carburettor e th , ds ee sp r we lo At . le id st fa e ov ab ds the air cleaner at engine spee extraction valve.

2

of fumes direct to atmosphere

is controlled

by a ventilator

’ ‘1 w re sc op st e th st ju ad e, lv va e th of g To check the correct settin

(Fig. 3.23) until a 2 mm

e lv va e th n ee tw be ed rt se in twist drill can be

lever and the stop screw post. ed ne so al ll wi w re sc op st le tt ro th e th 3 If this adjustment is necessary,

d. ee sp ng li id d ie if ec sp e th in ta in ma to re-adjustment

) 13 . ec (S r to et ur rb ca to er mp da g in Fig. 3.22. Refitt

42

Chapter 3/Carburation; fuel and exhaust systems

15 Carburettor - removal and installation

1. Remove the air cleaner cover and element, as described in Section 3. 2 Unbolt and remove the air cleaner body from the carburettor air intake flange. 3 Disconnect the fuel inlet pipe from the carburettor. 4 Disconnect the distributor vacuum pipe from the carburettor. 5 Disconnect the choke and accelerator controls from the carburettor. 6 Unbolt the carburettor from the inlet manifold and withdraw it. 7 Installation is a reversal of removal, but always use new flange gaskets.

16 Carburettor - dismantling and reassembly

Fig. 3.23. Float chamber vent valve setting (Sec. 14) 7

Stop screw

2

1

Throttle stop screw

i\ffWy |i

My il i| XX

i ih

Fig. 3.24. Exploded view of the carburettor Hydraulic damper Damper rod collar Cover

Spring Diaphragm retainer Flexible diaphragm Air valve piston Needle retaining screw OBNAAARWH ~ Metering needle

10 11 72 13 14 15 16 17 18

Body Temperature compensator Gasket Float chamber Jet adjuster Floats Float pivot pin Cold start device Throttle shaft

19

Throttle valve plate

OOO

Clean the exterior of the carburettor before dismantling.

Chapter 3/Carburation; fuel and exhaust systems 2 The carburettor will normally only require dismantling to renew a split diaphragm or to check and adjust the float level. Dismantling the is not mechanism throttle valve plate or shaft or the choke recommended

and if these components are worn it will be preferable to

purchase a new or rebuilt unit. 3 Withdraw the hydraulic damper. 4 Unscrew the four cover securing screws and remove the cover. 5 Extract the spring, the air valve piston/diaphragm assembly, complete with metering needle. 6 \f the diaphragm is to be renewed, unscrew and remove the retaining ring. 7 To remove the float chamber, pull off the jet cap and unscrew and remove the six securing screws. Pull the float chamber from the

carburettor body. If it is stuck tight, rotate the jet adjuster slightly, having first made sure that the relative positions of float chamber and jet adjuster have been marked in manufacture, otherwise do so now. On no account attempt to remove the nylon plug from the centre of the jet adjuster. 8 Extract the float pivot, remove the twin floats and then unscrew the

inlet needle valve, noting the integral filter.

) ed ow rr (a er sh wa n lo Ny . ly mb se as t je e th of s t n e n o p m o C . 29 Fig. 3.

(Sec. 16)

43

9 If essential, the metering needle can be detached from the air valve piston after releasing the grub screw. 10 Clean all components and renew any that are worn. Obtain new gaskets, seals etc. as necessary or in the form of a repair kit. fitted 11 Screw in the needle valve ensuring that the original washer is or one of equivalent thickness. 12 Refit the float and then check the float level. To do this, invert the carburettor and with the weight of the floats on the needle valve, measure the dimension ‘A’ (Fig. 3.28) which is between the highest

point of the float and the flange (gasket removed) of the carburettor body. If this dimension (0.63 to 0.67 in./16.0 to 17.0 mm) varies, bend the tag which contacts the end of the needle valve. 13 If the jet assembly has been removed and dismantled, reassemble it and screw it into position making sure that the washers and ‘O’ rings are

correctly located. 14 Screw the jet adjuster fully into the carburettor body, install a new float chamber gasket and the float chamber itself.

15 If the metering needle has been removed from the air valve piston, reassemble it so that the nylon washer is flush with the face of the air valve piston.

) 16 . ec (S on st pi e lv va air in le ed ne ng ri te Fig. 3.30. Setting me

44 $$

—

Chapter 3/Carburation; fuel and exhaust systems eS

EEE

16 Make sure that the grub screw is not overtightened and that it mpinges on the flat that is ground on the side of the needle casing, otherwise the needle will not be biased away from the depression holes

With condition (ii) turn the adjuster jet clockwise (when viewed from above) to weaken the mixture and then repeat the test.

n the face of the air valve piston. The metering needle calibration number is visible if the needle is pulled gently from its casing. 17 To install the new diaphragm, engage the tongue on the diaphragm ower face with the slot in the air valve piston rim. Fit the diaphragm etaining ring.

from above) to enrich the mixture and then repeat the test. Do not turn the adjuster jet more than % turn at a time between tests. 24 It is emphasised that the foregoing procedure is not precise and a CO meter should be employed to accurately set the position of the jet adjuster. If necessary, the idle trim screw can be unscrewed (not more than four complete turns) to attain the necessary exhaust emission

'8 Insert the air valve/diaphragm assembly, taking great care not to damage the metering needle as it enters the jet. Engage the tongue on the upper edge of the diaphragm in the slot in the carburettor body. 19 Install the cover so that the projection on the hydraulic damper housing is towards the air cleaner mounting flange. 20 Install the carburettor to the engine and top-up the damper, as

described in Section 13. 21 It will be remembered that the jet adjuster has been screwed fully in to facilitate installation of the float chamber. Before the engine is started, it must be unscrewed two complete turns using a ‘C’ spanner or other suitable tool. 22 Start the engine (this will take a little longer than usual as the float chamber is empty) and run until normal operating tempe.ature is reached. 23 Check all the adjustments given in Sections 11, 12 and 14 and then check the mixture quality by lifting the air valve piston 0.04 in. (1.0 mm) using a thin screwdriver inserted into the carburettor air intake. With the engine idling, the action of lifting the air valve piston will produce one of the following reactions: (i) Engine speed rises momentarily and then resumes normal (ii) (iii)

idling - mixture correct. Engine speed rises and remains at this higher level before returning to idling - mixture rich. Engine speed drops or engine speed stalls - mixture weak.

With condition (iii) turn the adjuster jet anticlockwise (when viewed

levels (2.5 to 3.5%).