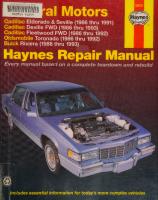

Chilton's General Motors Deville/Fleetwood/Eldorado/Seville 1990-98 Repair Manual [28540] 0801991048, 9780801991042

“"28540"--Cover "Covers all U.S. and Canadian models of Cadillac Deville, Deville Concours, Eldorado, Fl

129 3 42MB

English Pages 358 Year 2000

Recommend Papers

![Chilton's General Motors Deville/Fleetwood/Eldorado/Seville 1990-98 Repair Manual [28540]

0801991048, 9780801991042](https://ebin.pub/img/200x200/chiltons-general-motors-deville-fleetwood-eldorado-seville-1990-98-repair-manual-28540-0801991048-9780801991042.jpg)

- Author / Uploaded

- Joseph D'Orazio

- Eric Michael Mihalyi

- Similar Topics

- Technique

- Transportation: Cars, motorcycles

File loading please wait...

Citation preview

28540

jimmmmmmmiii 1990-98 REPAIR

MANUAL

Covers

all U.S. and Canadian models of Cadillac DeVille, DeVille Concours, Eldorado, Fleetwood and Seville Front Wheel Drive Models

i^r^,

7See It

impossible to anticipate

IS virtually

all ol tlie

hazards involved with automotive maintenance and service, but care

and

common

sense

will

prevent

most accidents The rules

ol safety for

smoke around

"don't

tool(s) lor the iob." to

mechanics range trom

gasoline." to "use the proper

The

avoiding injuries

Irick to

is

develop sale work habits and to take every pos-

sible precaution

Do keep

a

lire

extinguisher and

lirst

aid

kit

handy. y

Do

Fig.

vrear safety glasses or

16 Screwdrivers should be kept

good condition

to

trom the screw

MSC

in

prevent injury or dam-

age which could result

IMC

goggles when cut-

it

the blade slips

GENERAL INFORMATION AND MAINTENANCE

1-7

FASTENERS. MEASUREMENTS AND CONVERSIONS Bolts, Nuts

to

and Other Threaded

deform w/hen tightened or

Whenever retainers

>

See Figures 20, 21. 22 and 23 Although there are a great variety

ol lasteners

that in

the

monly used

modern retainer

car or truck, the is

bolts, screws, studs, etc).

may

most com-

Most threaded

Some

it

note any special

of

which

removed and replace any

damage. Check

all

threads for

which can increase the torque

that fastener

damaged

retainers (such as

stretch bolts or torque prevailing nuts) are

is

was

originally selected. Addi-

be sure that the driver surface

tener has not been

of the fas-

compromised by rounding

or

designed

In

some cases

may

a driver surface

rounded, allowing the driver

partially

to catch in only

one direction

occurrences, a fastener

In

may be

many

ol these

installed

and

tight-

ened, but the driver would not be able to grip and

loosen the fastener again. (This could lead to frus-

down

tration

need

necessary to achieve the desired clamp load for

retainers

be reused, provided that they are not

use or during the repair

when

show signs

tionally, in

will

which should be replaced during a proce-

rust or corrosion

the threaded fastener (nuts,

damage.

other

become only

we

possible,

dure. But you should always inspect the condition ol a retainer

lound

use and should not

in

be reinstalled.

Retainers

If

the line should that

use the proper replacement.

same

whether due

fastener,

design or damage, you must

of the

component ever

be disassembled again).

to

you must replace a

ALWAYS In all

design, material and strength should be

used. IVIarkings on the heads ol most bolts

determine the proper strength

same

to

be sure to

cases, a retainer

will

ol the fastener

help

The

and pitch must be selected

material, thread

assure proper installation and safe operation

to

of the

vehicle afterwards.

Thread gauges are available to help measure a

Most automotive and hardware

bolt or stud's thread.

stores keep gauges available to help you select the size. In a pinch,

proper

bolt for a thread gauge. is

not too badly

you can use another nut or II

the boll

by finding another bolt which place.

the

If

you

find a nut

damaged

bolt,

Fig.

20 Here are a few

of ttie

is

will

select a

thread

match

in its

which threads properly onto

then use that nut to help select

the replacement bolt.

replacing

you are replacing

damaged, you can

If

however, the bolt you are

so badly damaged (broken or

drilled

most common screw/bolt driver styles

MMrT D

pp

\m

LTJ

\

-

3

-

;

-

3

-

E = -

—

Length Diameter (major diameter) Ttireads per

inchi or

mm

Triread length

Size of the wrench required Root diameter (minor diameter) TCCSI038

(CASTELLATED) Fig.

22 Threaded retainer sizes are deter-

mined using

tliese

measurements

T LOCKWASHERS

@

@ Fig.

23 Special fasteners such as these

Torx" head bolts are used by manufacturers to discourage people from working on Fig. 21 Tliere are

many

different types of tlireaded retainers found

on veiiicles

vehicles without the proper tools

GENERAL INFORMATION AND MAINTENANCE

1-8 out) that

Ifireads

Its

same assembly which

vehicle)

cannot be used as a gauge, you

by looking

migtit start

mounting

It

lor anottier boll (Irom the

or a similar location

will

thread into the

so. the other boll

H...go«

on your

damaged

bolt's

can be used to select

a nut; the nut can then be used to select the

replacement bolt cases, be absolutely sure you have

In all

selected the proper replacement. Don't be shy, you

can always ask the store clerk

tor help.

when you find a bolt with may also find the nut it was threaded into has also been damaged. If this is the case, you may aware

I

that

damaged

threads, you

He««on

or drilled hole

have

and tap the hole, replace the

to drill

nut or otherwise repair the threads.

replacement bolt

try to force a

damaged

to

fit

H...,oo

NEVER

Ixadboll

into the

threads. ll«^«boll

Torque

is

defined as the measurement ol resis-

tance to turning or rotating.

about an axis this

It

tends to twist a body

A common example

of rotation

would be tightening a threaded

retainer

a nut, bolt or screw Measuring torque

common ways

most

retainer has

When applied

in

ol the

assure that a threaded

is

three distinct areas, the head, the bear-

and the clamp

measured torque

bearing

one

haad to help

been properly lastened

tightening a threaded lastener, torque

ing surface ol the

is

triction.

This

is

load.

About 50 percent

used

in

overcoming

the friction

is

between the

bearing surface of the bolt head, screw head or nut lace and the base material or washer (the surface

on which the fastener

mately 40 percent

overcoming thread 10 percent lul

as

clamp load

much

of the

is

rotating).

(the lorce

means

Approxi-

applied torque

triction

is

used

in

This leaves only about

of the applied torque to

together). This

develop a use-

which holds a

that friction

joint

can account lor

as 90 percent ol the applied torque on a

lastener

TORQUE WRENCHES > See Figures 24, 25 and 26 In

used

most applications, a torque wrench can be to

assure proper installation ol a fastener

Torque wrenches come

in

various designs and

most automotive supply stores

will

carry a variety

Q=

czhbi^ ^^snzin xcsiois

Fig

t>e«d toll

ol

such as

24 Various styles

of

torque wrenches

are usually available at your local auto-

motive supply store

bolt

GENERAL INFORMATION AND MAINTENANCE your needs^

to suit

A torque

for

a fastener.

A

torque wrencfi can also be used

»

no worldwide standardization

is

See Figures 28 and 29

>

of fasteners,

Some

may

type)

allow

be equipped with a pivot head which can

to be

it

A

torque wrenches (usually of the click

m

used

areas of limited access,

BUT

the charts are a general guideline and should be

it

used with caution. Again, the general rule

wrench, grasp the handle lightly and as you pull

you are using the

right tool lor the job,

of

"if

you should

must be used

on the handle,

it

properly. To hold a pivot

point.

here.

extension during the process of pulling, there very

Beam Type

point.

See Figure 27

to

The beam type torque wrench It

is

one

most

of the

The design

in

(shaft) to a scale located near the handle.

is

pulled, the

beam bends and

beam

As the

make

it

Click (Breakaway) Type

Another popular design

To use the

to a

of

torque wrench

click type

is

the

wrench you pre-

torque setting. Once the torque

the torque readings will be inac-

of the

handle

is

val-

they

any position on the wrench without

to

be compact, easy to

read and have a great degree of accuracy.

is

usually such as

TORQUE ANGLE

causes a momentary breakaway of the torque

wrench body sending an impulse

»

IVIETERS

See Figure 31 I

the frictional characteristics of each fas-

clamp loads which

tener or threaded hole will vary

U-joInt,

be mentioned

ttiat tlie

wobble or extension

will

use of any

have an

what wrench you are using. For the most

are based strictly on torque will vary as well.

most

applications, this variance

effect on the torque readings, no matter

enough

type of

a manufacturer's engineers

cause worry. But,

to

in

is

may determine

precise clamp loads are necessary (such

on the wrench

with

driver.

If

necessary, straight

many aluminum

cases, a torque angle

cylinder heads).

method

In

not significant

certain applications,

accurate readings, install the socket directly

In

more

that

is

the case

these

of installation

would

the wrench driver) will have the least effect on

be specified.

the torque reading. Avoid any extension that

torque angle tightened, a predetermined seating

alters the length of the to the

wrench from the handle

head/driving point (such as a crow's

is

reached, the wrench has a reflex signaling feature that

is that

a

extensions (which hold a socket directly under

it

show torque

wrenches

inconvenient to deliberately misuse the

i»\\ sliould

the pointer

I See Figure 28

adjust

at

of these

because they tend

ferred

contact with the yoke

dial indicator to

accuracy These wrenches are often pre-

affecting

indicates the torque using the scale.

click type.

case or direct reading torque wrench

One advantage

wrench.

consists of a pointer attached to

the head that runs the length of the flexible

is

good chance

comes

ues.

curate because this could alter the wrench loading

popular types.

wrench

the handle

If

rigid

equipped with a

can be held

head

should be floated on the pivot

not have to strain to tighten a fastener" applies

>

See Figure 30

if

you are following the general guidelines in ttie accompanying charts. Keep in mind that because there

Rigid Case (Direct Reading)

Head Type

Pivot

wrencti should be

used any time we supply a specific torque value

1-9

foot). U-joInt or

wobble extensions can greatly

affect the readings; avoid their

use

at all

times.

to the operator's

When

installing fasteners

which are

torque and standard torque wrench are usually used first to

remove any compliance from the

fastener

joint.

The

then tightened the specified additional

is

portion of a turn measured in degrees,

A

angle gauge (mechanical protractor)

used

is

torque for

these applications. hand.

tVOTEO HANDLE

-DRIVE SOUABE

Fig.

28 A click type or breakaway torque

wrench

beam

27 Example

Fig.

29 Torque wrenches with pivoting

of a

—

note that this one has a pivoting

head

type torque wrench

Fig.

PIVOTED HANDLE TOROUE WRENCH

heads must be grasped and used properly to prevent

an incorrect reading

Fig.

30 The

rigid

case (direct reading)

Fig. 31

Some

use

show torque

protractor)

of

specifications require the

a torque angle meter (mechanical

torque wrench uses a dial Indicator to

1-10

GENERAL INFORMATION AND MAINTENANCE their installation

Standard and Metric

(It

lbs

kPa or >

Some

ol the

surements include length

Measurements See Figure 32

.

inch lbs or

mm Hg)

the proper

In

(in

Nm) and

common mea-

most or

cm/mm), torque

pressure

most cases, we

(psi. in

Hg,

strive to provide

measurement as determined by the man-

this

manual, specifications are given

Though,

you determine the condition

components on your

of

in

some

cases, that value

may

not be

conveniently measured with what

you

in

is

available in

ol the

measurmg will

have two

scales so the Standard or Metric measurements

may

easily be taken

II

any

ol the

tools which are available to

various measuring

you do not contain the

scale as listed in the specifications, use the

accompanying conversion

various

vehicle, or to assist

many

devices wtiich are available today

same

ufacturer's engineers

Throughout to help

your toolbox Luckily,

proper value

factors to determine the

GENERAL INFORMATION AND MAINTENANCE The conversion

used by taking the

lactor chart is

given specification and multiplying

first line,

you have a measurement

if

SERIAL

NUMBER

in

as "free-play should be 2 only

by the neces-

it

in

inches such

in.

50.8mm.

Likewise,

if

the specification

parts to be certain of the vehicle

A

Identification

Number

plate that

upper instrument panel and

is

is

17 characters

(VIN)

ber

is

used

for title

trol of

left

that represent

body

type, engine,

number.

It

is

a l^etric measurement, for example in

the

then look at the center

measurement

is

assembly

year,

and engine

ft.

identi-

applied to the engine and

used

may

for in-plant

con-

be used by law

proper

bers and letters as the vehicle identification

in a

num-

ber.

The eighth engine

line, series,

and consecutive

is

officials to identify

unit

in

digit of the

VIN plate

will specify the

the vehicle. All engines have a nine-digit

engine identification number.

important for servicing and ordering

VEHICLE IDENTIFICATION NUMBER digit Vehicle Identification Number used for license ond insurance identification and in qenerol reference to the outomobile. The number is located on a plate riveted to the windshield lower frame at the driver's side of the vehicle where it is visible through the windshield The 1997 Codilloc Vehicle Identification number is decoded as follows:

Eoch 1997 Codilloc corrres a 17

1G6KD52BXVU NATION OF ORIGIN

200001

-

1=USA

production sequence number

MANUFACTURER -

200001 = oeville/concours/o-elegance 600001 = eldora6o/etc 800001 = seville sls/sts

G=GEf4ERAL MOTORS

ASSEMBLY PLANT

CARUNE/SERIES

U = HAIlN

KE " DEVILLE O'EUEGANCX

KF = OEVILLE CONCOURS KO = DEVILLE EL = ELDORADO

MODEL YEAR•OtECK

KY = SEVILLE TOURING SEDAN (STS)

VIN

• 57 COUPE 2 1 5 = 69 SEDAN 4

I

ENGINE CODE

BODY CODE -BODY TYPE DOOR N0TCH8ACK OOOR / 4 WINDOW NOTCHBACK

Vehicle liientification Information— 1997 Cadillac shown, others similar

ENGINE AND VEHICLE IDENTIFICATION

V = 1997

DIGIT

(SEE BELOW)

New-

column

100 Nm, multiply

condensed form should contain the same num-

num-

and registration purposes and

model

If

the conversion factor of 0.738 to get 73.8

was given

engine/chassis combinations. This number

number con-

codes supplying

indicates the vehicle manufacturer, country of origin, type of restraint system,

is

these assemblies and

enforcement or other

visible through the

important information about your vehicle. The

number

transaxle. This derivative

is

fastened to the

windshield. The vehicle identification tains

in

Me[&s (Nm),

first.

nine-character derivative of the vehicle iden-

tification

The Vehicle

ton

fication.

See Figures 33 and 34

stamped on a metal

by the conversion

IDENTIFICATION

Vehicle Identification Plate I

only

but your ruler reads

in."

millimeters, multiply 2

factor of 25.4 to get the metric equivalent of

sary conversion factor. For instance, lool

See Figures 38 and 39 The transmission has two Identltying stamp-

ings: the transmission identification derivative.

and the VIN

The transmission Identification number

gives the transmission model, build dale, and the application code. The transmission identlllcation

FRONT OF CAR

number

Is

stamped on Ihe automatic transmission

case The VIN derivative

complete VIN and

is

Is

created from the

stamped

In

two

different

places.

Fig.

38 The location

ol the transaxle

stamping on the rearward corner

ol the

box

JULIAN DATE

OF THE YEAR SHIFT AND

TRANSAXLE

-LINE NUMBER

BROADCAST coot VEHICLE IDENTIFICATION NUMBER DERIVATIVE LOCATED ON PLATE ON ENGINE BLOCK IN FRONT OF

H-WILLOW RUN PLANT

THANSAXLE EXTENSION VISIBLE WITH VEHICLE ON HOIST Fig.

35 Engine identification number loca-

tion—4.6L

Norltistar V-8

SERIAL

NUMBER

iN

BASE CODE 31

Fig.

36 Engine Idenlltication location

lor

Ihe 4.5 and 4.9L engines

Fig.

37 This label

m

the engine

com-

partment contains emissions information

among

other things

Fig

39 The transaxle VIN derivative number

(1) Is

stamped

into the horizontal cast rib

right-hand rear ol the transaxle housing, the transaxle ID nameplate (2)

ward

ol the

VIN derivative

is

on Ihe

located just lor

1-14

GENERAL INFORMATION AND MAINTENANCE

ROUTINE MAINTENANCE

GENERAL INFORMATION AND MAINTENANCE >

cracks and tears.

See Figures 40 and 41

If

the ducting

1-15

torn

is

it

should be

placec

Proper maintenance and tune-up long and trouble-free vetiicle

can yield

its

own

to

The

and the work

actiieve better gas mileage

As a conscientious owner and

down which

the parts cost you, the date, and the ter

reading

Keep

at the time.

items as engine

oil

and

referred to in case of related

main component

how much exact odome-

The

In

to deter-

will

maximum and

originally delivered includes the factory

this literature,

provided

in

If

recom-

case you do not have the factory

Fig.

Fig.

42 Before any work can be done on side of the engine compartment,

Remove

to

remove the

strut rod.

See Figures 42

it.

The

the bolt at the radiator frame

fasteners are clips,

Remove

5.

Wipe

6.

To

the air

some

filter

are screws,

cover back to

in

the air

filter

element.

out the housing with a clean rag.

7.

Position the

make sure

it

air filter

element

in the

hous-

seats properly

Install the air

intake air duct

cleaner cover. Connect the

and tighten the clamp.

Install the lAT sensor,

if

removed, or recon-

nect as necessary

thru 52

cleaner

tilt

install:

10.

the engine compart-

air intake

Install the air

cleaner fasteners, and tighten

as necessary.

ducting for

Fig. 41 This sticker, located in the

engine compartment, gives

serpentine belt routing, as well as other pertinent information

Fig. it

of

expose the element.

40 This vehicle sticker gives the gross vehicle weight and body

left

duct as necessary.

Carefully

4.

ing,

air

air

depending on the vehicle configuration.

should be replaced every 30.000 miles

ment. Inspect the flexible

necessary

»Some

remove

otherwise, never run the engine without

Locate the

in the

duct clamp and

air

Disengage the fasteners securing the top

3.

reduce the potential for water

REMOVAL & INSTALLATION

lit-

equipped and mounted

if

airflow possible with a minito

configuration, as well as the federal law compliance

the

remove the

8.

I

temper-

or disconnect the intake air

Loosen the intake

9.

A maintenance schedule

replaced

the air cleaner.

you no longer

erature.

is

the air

it

replacement copies are usually

may be

element

cleaner housing.

an engine maintenance procedure requires

be invalu-

provided with your vehicle when

available from the dealer. is

is

potential

(50,000 km). literature

mended maintenance schedule. have

system

removes

cleaner housing and ducts are designed to

of noise,

air filter

The

air

2.

ingestion into the engine.

case of a

able.

was

of the air intake

Remove

1

ature (lAT) sensor,

flow restriction. The

the temporary removal of the air cleaner, it;

warranty problem, these receipts

air

mum If

was perlormed.

maximum

engine contaminants, particularly abrasive types.

do-it-yourselfer,

these receipts are the only proof you have that the required maintenance

minimum

the air cleaner element that

allow the

so that they may be

problems or

mine operating expenses. As a

with

air cleaner

easily.

cleaner assembly The air cleaner assembly houses

to jot

receipts for such

all

fillers,

element provides

flat air filter

air filtration

Keep your own personal log

services you performed,

A

driver, set

check or replace items that could cause major later.

The

air to the

cleaner assembly, resonator assemblies and

air

hoses.

aside a Saturday morning, say once a month, to

problems

system provides clean

induction noise. The intake air system consists of

an

an out-ol-tune

ttian

intake air

engine, optimizes airflow, and reduces unwanted

rewards. Studies fiave sfiown

tuned and maintained vetiicle can

that a properly

vehicle.

life,

is ttie l

supply solenoid and lines

uum

lines to the throttle

24.

25.

manifold bolt tightening

26.

sequence— 4. 5L and 4.9L engines

hose.

or retained in

sequence so they may be reinstalled

in their

original positions.

Remove

the right front and rear

the intal

4. 91

Engines

See Figures 54, 55 and 56 1

Disconnect the negative battery cable.

2.

Drain and recycle the engine coolant.

3.

Remove

the air

filter

assembly Disconnect

and remove the coolant recovery

tank.

4.

Disconnect and remove the cross brace.

5.

Remove

the water

Remove

the serpentine drive belt and the

6.

water

pump

pulley

pump

pulley bolts.

3-15

ENGINE AND ENGINE OVERHAUL

3-16

HRrdHBilGB Fig.

58 Remove the water pump

Remove

Fig. 61

tlie

pump

water

pulley retaining boit and

.

.

bell

adjuster

Fig.

59 Loosen the water

Fig.

62

.

.

.

pump

belt

remove the pulley from the

water pump

.

Cylinder Head

REMOVAL & INSTALLATION

4.5L and 4.9L Engines >

See Figure 65

RIGHT SIDE 1

Disconnect the negative battery cable. Drain

the engine coolant.

2 Fig.

3

64 Remove the water pump from the

Remove Remove

rocker

arm covers.

the lower intake

and

right side

exhaust manilolds.

engine and thoroughly clean the mounting

4

surlaces

tube

11

Inslaliihe drive belt

12

Tighten Ihe water

lbs (30

pump

pulley bolts to

22

It

Nm) cleaner

assembly

13.

Install the air

14

Connect the negative battery cable

15

Fill

cooling system and checl< lor

the engine and allow

it

temperalute Rpcheck

^Because

to

for

come i':>a'»:s

to

leal(S

Start

normal operating

Top-ud

I'n^

roolant

the engine block and radiator are

aluminum, make sure the antifreeze solution Is approved for use in cooling systems with a high aluminum content GM recommends the use

of a

supplement/sealant 3634621 or equiv-

alent, specifically

num engines

designed

to protect Ihe

for

use

in

alumi-

engine from

Remove engine

lift

bracket and

oil

dipstick

ENGINE AND ENGINE OVERHAUL Remove

4

the intake manifold-to-engine bolts

and intake manilold^

the exhaust manifold-to-cylinder head bolts

and the

exhaust manifold,

Remove

and the

the engine lifting bracket

Access

the timing chain guides.

screws

through the plugs

is

the

at

front of the cylinder head.

pipe, the exhaust pipe-to-exhaust manifold bolts,

6,

Removing

5.

to the retaining

Disconnect the exhaust manifold crossover

5,

3-17

6-

Remove

the water crossover.

7.

8.

Remove Remove

the cylinder head bolts.

9.

Remove

the cylinder head and gasket.

the exhaust manifold.

dipstick tube,

Remove

7,

move

the AIR bracket-to-engine bolts and

the bracket aside.

Remove

8,

With the camshafts remaining In the cylinder head some valves will be open at all

the cylinder head-to-engine bolts

and the cylinder head.

times. Do not rest the cylinder head on a

To install:

flat

Clean the gasket mounting surfaces,

9,

10.

Install

new head gasket

service with the cylinder face down, or

damage

valve

over dowels on

will result.

11.

Install

To

cylinder head,

Apply a suitable lubricant

12.

to the cylinder

14.

Tighten bolts,

head bolts

in

ft.

lbs.

lbs.

ft.

ft,

lbs,

18.

sequence,

to

lift

1

3 and 4 cylinder head bolts

,

AIR bracket.

Install dipstick

bracket,

Install

Using a new cylinder head gasket,

11

the cylinder head and the 10 1^111 and 3

exhaust manifold.

lower intake

Install

rocker

arm covers,

19.

Install Fill

21

Connect negative battery cable,

the 10

cooling system

Start

M6

Lube the washer and the underside

Mil

oil prior to installation.

bolts in

Allow engine

to

Tighten the 3

for coolant, oil

come

to

normal operating temperature and recheck

M6

sequence

bolts to

10

to

22

lbs,

ft.

Drain the engine

Install the

13.

Set the camshaft timing. Install the

14.

it

on

3,

Remove

the 13

oil

pan bolts and remove the

pan,

(30

Nm)

pan gasket is reusable unless damaged. Do not remove the gasket from the oil pan groove unless replacement is required.

•»The

oil

To

install:

4,

Install

camshafts.

12.

a new

oil

pan

seal,

if

required by start-

pan groove and working the

camshaft guide bolt access hole seal into the

plugs

assembly and place

oil,

head

ing the seal into the

tor

leaks.

the engine

2,

of the bolt

Tighten

(12 Nm).

lbs,

ft,

Remove

a stand,

install

plus 90°, plus an additional 90°for a total of 180",

engine and check

fuel leaks.

See Figures 68 and 69

oil

bolts.

head with engine

20.

%

1

avoid damaging the sealing surfaces.

tube and

manifold,

22.

cleaning aluminum gasket services, use only plastic or wood scrapers and/or an appropriate chemical dissolving agent to

(120 Nm),

Install

engine

in

(90 Nm).

Tighten No,

17.

and

Connect the negative battery cable.

.

4.6L Engine

16.

90

the crankcase

Fill

1 1

(50

When Tighten cylinder head bolts,

15.

to

pan installation—4.5L and

10-

finger-tight

sequence, to 38

Oil

engines

Clean the gasket services and combustion

chamber.

Install cylinder

Nm).

68

4. 91

install:

10.

head bolt threads. 13.

67

Fig.

cylinder block with either side facing up,

groove

in

both directions.

the cylinder heads. The plugs should be

in

seated and snug,

4.6L Engine »

^Because

Install the intake

15.

harmonic balancer,

See Figure 66 of the bulic

and complexity

4.6L engine, cylinder head removal

of ll)e

may

best

manifold, camshaft covers,

front cover

and

oil

16

Install the

water crossover.

17.

Install the

exhaust manifold,

18.

Install

pump,

Once the seal Is exposed to oil, it will expand and no longer stay in the groove If this happens, replace

without wrinkles.

the powertrain assembly.

with a

new

seal.

be accomplished with the engine out of the vehicle. For this procedure

economical

to

remove the

and cradle out the bottom

It

may be most

5.

entire powertraln of the

body and

1.

Remove

the powertrain assembly.

2.

Remove

the intake manifold, camshaft

covers, harmonic balancer, front cover and

4.5L and 4.9L Engines

oil

>

pump.

Remove

3.

ft.

REMOVAL & INSTALLATION

as an engine stand.

utilize the cradle

install

to

See Figure 67

the chain tensioner from the timing

Disconnect the negative battery cable. Raise

1.

chain

for the cylinder

4.

Remove

the

head being removed.

cam

and

sprockets from the head

being removed. The timing chain remains

in the

safely support the vehicle. Drain the crankcase.

Remove

2.

the 2 torque converter/flywheel

covers from the lower side of the transaxle.

chain case.

On

3.

the Eldorado

and

Seville,

remove

the

exhaust crossunder pipe and reposition.

Remove

4. oil

the

oil

pan-to-engine bolts and the

pan.

To 5.

install:

Clean the gasket mounting surfaces.

»Apply

a V* inch bead of

RTV

at the rear

main

bearing cap and front cover to block joints. 6.

Install the oil

pan and

bolts,Tightento14ft, 7.

Fig.

66 4.6L cylinder head tightening

sequence

Install the

lbs,

oil

pan-to-engine

(18Nm),

exhaust crossunder pipe.

the 2 torque converter/flywheel covers.

8.

Install

9.

Lower the vehicle.

lbs.

Position the

oil

pan to the crankcase and

the 13 retaining bolts. Tighten the bolts to 9

(10

Nm)

in

the sequence

shown

3-18

ENGINE AND ENGINE OVERHAUL

-# .g

Fig.

69

Oil

pan

boit torque

—4.6L engine

sequence

ENGINE AND ENGINE OVERHAUL 11,

Use

installer J

29774

or equivalent,

and

bottom the hub out on the crankshaft, 12,

Install the

crankshaft

washer and tighten

to

70

ft,

damper lbs,

and

(95 Nm),

13,

Install the right front air deflector

14,

Install the right front

wheel and

Raise and safely support the vehicle,

3.

remove the

bolt

Lower the

16,

Connect the negative battery cable.

vehicle,

right front

Remove

4.

wheel

the splash shields from the wheel-

house and remove the brace between the

pan

oil

and the transmission case. Support the engine cradle and remove the 3

5.

tire,

15,

3-19

bolts from the right side of the cradle.

Disconnect the

6.

RSS

sensor from the right

lower control arm,

4.6L Engine »

See Figures 75, 76 and 77

Install the

7.

equivalent and remove the balancer bolt.

Lower the engine cradle enough

8.

Fig.

damper—4. SL and

73 Crankshaft and

1

Disconnect the negative battery cable.

2.

Release tension from the accessory drive

tlywheel holder tool J 39411 or

ance

tor clear-

of puller tool, Install pilot tool

9.

J39344-2

into the

end

of

the crankshaft,

4.9L(

Remove

10. tool

HARMONIC BALANCER

J3841 6

To

the

harmonic balancer using puller

or equivalent.

install:

Position the balancer to the crankshaft and

1 1

using tool J39344 or equivalent,

ft,

install the balancer.

Clean the balancer bolts threads and apply

12. oil to

the threads. Tighten the balancer bolt to

lbs,

105

(145 Nm); plus 120 degrees. Raise the engine cradle into place and

13.

install the

3 bolts. Tighten the 3 bolts to 75

ft.

lbs.

(100 Nm).

74

Fig.

damper—4.5L and

Installing

4.9L

Reconnect the suspension position sensors

14.

to the lower control

Remove

15.

To

the

install:

Lubricate the bore of the

10.

hub and

75 Removing the harmonic bal-

16.

lubricant,

Position the

1 1

up the key

damper on

the cranl

side of the engine cradle. side engine cradle

16.

Install the right

17.

Install the right front air deflector.

18.

Install the right front

Lower the

19.

wheel and

body

1

Disconnect the negative battery cable.

2.

Remove

3.

Raise and safely support the vehicle.

4.

Remove

tire,

vehicle,

Fig.

Connect the negative battery cable,

20.

See Figures 78 and 79

bolts,

76 Installing the harmonic balancer—

4.9L Engine

See Figures 73 and 74 1

Disconnect the negative battery cable.

2.

Remove

3.

Raise and safely support the vehicle

the serpentine belt.

securely. 4.

Remove

the right front wheel and

5.

Remove

the right front air deflector.

6.

Loosen and reposition the heater by-pass

7.

Remove

tire.

line.

the crankshaft

damper

bolt

and

washer. 8.

To 9.

EP

Install

a puller and

remove the damper.

install:

Lubricate the bore of the hub and seal with

lubricant.

10.

Position the

up the key shaft.

damper on the crankshaft

slot in the

the right front

front air deflector.

4.6L engine

I

the serpentine

lining

hub with the key on the crankFig.

77 Tightening the harmonic balancer bolt— 4.6L engine

belt.

tire.

Remove

the right

3-20

ENGINE AND ENGINE OVERHAUL

ENGINE AND ENGINE OVERHAUL

82 Camshaft and timing cliain—4.5L and 4.9L engines

Fig.

1

Align Ihe timing nnarks on the sprockets;

b^

must lace

ttiey

eacti other,

Align the dowel pin

c.

and crankshaft.

Install the

CAMSHAFT SECONDARY DRIVE CHAIN

(50 Nm), Install

new

the

and

thrust button

install the

slinger to the crankshaft, 7.

Install

8.

Refill it

Fig.

Remove Remove

3,

Remove

the

left

side secondary chain ten-

Remove

the

left

side chain guide. Access the

the front cover. Connect the negative

83 Primary timing chain— 4. 6L

the front cover. the

side

left

cam

covers,

SETTING CAMSHAFT TIMING

sioner, 4,

upper chain guide mounting bolt through the hole

in

4.6L Engine

the cylinder head covered with the plastic plug.

battery cable,

allow

5

2,

1

ft.

INTERMEDIATE SHAFT PRIMARY CHAIN

SHAFT SPROCKET CRANKSHAFT SPROCKET KEY SPROCKET

See Figure 84

camshaft sprocket-

sprocket-to-camshaft sprocket bolt to 37 lbs,

2

3 INTERK^EDIATE 4

>

to-camshaft bolts. Tighten the camshaft

6.

engine assembly or the power-

assembly

the camshaft with

Slide the assembly onto the camshaft

d.

Install the

13, train

in

the index hole in the sprocket.

oil

the cooling system. Start the engine,

to reach normal operating temperatures and

Remove

5,

the

side

left

cam

sprocket bolts and

I

See Figures 85, 85 and 87

sprockets, Setting camshaft timing

check for

leaks.

6,

Remove

7,

Repeat Steps 2 through 6

the secondary drive chain, the

4.6L Engine

chain

To

CAMSHAFT PRIMARY DRIVE CHAIN

is

if

cam

See Figure 83

being replaced.

Remove

1

necessary whenever

the relationship between any chain

been

install:

lost.

Correct timing exist

Retime the camshafts.

9,

Install the front cover.

Remove

cam

timing marks aligned and

all

4 camshaft drive

cover(s). surface.

the engine

assembly and put

it

and

ley

on

the serpentine drive belt, idler pul-

belt tensioner.

if

not

done previously.

3.

Remove

the front cover and

4.

the

5.

Remove Remove

6.

Remove

the camshaft sprocket bolt from

Remove

oil

pump.

covers.

the three timing chain tensioners.

four camshafts and 7.

cam

all

remove the sprockets.

the secondary drive chains from

around the intermediate shaft sprocket. 8.

Remove

the

mary drive chain

one

bolt holding the

mtermedi-

and slide the gears and the

ate shaft sprocket

off

the crankshaft

pri-

and intermediate

shaft.

>»The intermediate shaft need not be removed unless wear is evident. 1

To 9.

install:

10,

Install the oil

11,

Install

12,

Install the

and

the

belt tensioner.

INTAKE

C

3

EXHAUST CAMSHAFT SECONDARY CAM DRIVE CHAIN

4

CHAIN GUIDE

2

Retime the camshafts.

pump,

cam

covers,

serpentine drive

belt, idler pulley,

Fig.

that

the crank

pins are perpendicular (90°) to the cylinder head Install the

an engine stand or remove the powertrain assembly, 2.

such

and sprocket has

when

sprocket and the intermediate shaft sprocket have

8,

10.

is

drive system has been disturbed

the right side

their

»

3-21

84 Secondary timing chain-—4.6L engine

5

RH SPROCKET - INSTALL CAM PIN IN RE SLOT FOR EXHAUST POSITION; Rl SLOT FOR INTAKE POSITION SPROCKET INSTALL CAM PIN IN SLOT FOR EXHAUST POSITION; LI SLOT FOR INTAKE POSITION

6 LH LE

ENGINE AND ENGINE OVERHAUL

3-22

#'^^^^^

INTAKE POSITION

1

2

EXHAUST POSITION

3

TIMING

MARKS

Fig.

85 Setting camsliaft timing

Fig.

86 Camstiaft

cliain

guides

—4.6L engine

—4.6L engine

To allow access the lollowmg components

1

must be removed: a

cam

Both

b

Front cover

The three chain tensioners. The lensioners

2

The

oil

Install the

1

o clock position Use J

crankshaft and intermediate shaft

positions but must be

ing marks adjacent to each other

5

Install the

crank and intermediate sprockets

over their respective shafts

pump.

6

The primary and secondary chain guides

should be reinstalled

3

approximately the

to rotate the crankshaft.

sprockets to the primary drive chain with Iheir tim-

in their instatted

fully retracted. d.

IS at

4

c

may be

key

39946 covers

if

previously removed

Rotate the crankshaft until the sprocket drive

Rotate the crankshaft as necessary to

engage the crankshaft key changing the relationship each other Use J 39946

in the

of the

sprocket without

timing marks to

to rotate the crankshaft

ENGINE AND ENGINE OVERHAUL wThe RE cam

sprocket must contain the

cam

position sensor pick-up.

To

install:

4,

Install the

valve

5,

Install the

camshafts,

6,

Install the

camshaft cover

Use a

3. lifters in their

original bores.

lips

3-23

suitable prying tool between the seal

and the crankshaft and remove the

seal.

Camshaft, Bearings and Lifters Use extreme care

Rear

IVIain

to avoid damage to the crankshaft sealing surface. NOTE: The pre-

Seal

REMOVAL & INSTALLATION

ferred

REMOVAL & INSTALLATION oValve

lifters

and pushrods should be kept

Some engines

mm)

and overas original equipment. The

oversize lifters are etched with an

Remove Remove

1

2.

blies

the oversize

if

the

II

the intake manifold

on their

and

lifter

the

lifters.

available,

lifters is

A

body. The

and

is

as dry

started.

which

is

helpful for this proce-

Unbolt and remove the flexplate from the rear

must be primed before seize

lifters will

Submerge

when

the lifters in

down on

mm)

drift Into

the

lifter

remove the old any

Lubricate the

lip of

Using

seal with

wheel

a Seal Installer tool

(this is the

purpose

J-34604

1

of the installer)

or equiv-

mm

and

indented,

To complete the installation, reverse the

6,

removal procedures. Tighten the flexplate-to-crankshaft bolts to

and push

down

and the

new

over the crankshaft and

press the seal into place. The seal must be

flush with the block to

shaft.

37

ft.

lbs,

(52 Nm),

rollers

molybdenum-

Refill

Operate the engine and check

^

now primed. of the lifters,

a

it

oil,

submerged; do not pump the plunger. Release the plunger. The lifter is

Coat the bottoms

or equiv-

engine.

lifter is still

with Molykote® or an equivalent

J-26868

into the seal bore with the spring facing inside the

installa-

the engine

SAE 10

tool

Thoroughly clean the

seal.

leftover seal material with a clean

rag.

square

the plunger. Hold the plunger

while the

the crank-

for leaks.

1

> 1

2 3

disulfide lubricant before installation. Install the lifters

and pushrods

into the

engine

4

Fig.

manifold gaskets and mani-

Install the intake

88 Rear main seal removal toolFig.

4.SL and 4.9L engines

fold. 7.

90 Rear main seal installation—4.6L

engine Position the rocker arms, pivots and bolts on

the cylinder head. Position

and rocker 8.

SEAL SPRING

BLOCK ASSEMBLY CRANKSHAFT

in their original

order, 6.

sealant at the

the transaxle.

Using a Seal Removal

3,

alent,

very thin. Carefully insert the end of a

Va inch (3

5.

Remove

5-

lifters

RTV

of the crankshaft,

4,

special tool for remov-

install;

i»New is

1,

2,

seal bore of

dure.

To

Place a small amount of

upper/lower crankshaft seal.

J-26868 or equivalent, and a Seal Installer tool J-34604 or equivalent. tool

bearing grease. Position

Remove

install:

4.

Removal

about 10

in

To

crankshaft split line across the end of the

arm assem-

minutes.

tion,

See Figures 88 and 89

alent,

solvent should dissolve the varnish

ing

»

end

are coated with varnish, apply

carburetor cleaning solvent to the

4.

spark plug

and

install the

rockers

shaft.

Install the «(ires,

valve covers, connect the

and

install the air

cleaner

assembly.

»An

EP lube, such as EOS, should always be added to crankcase for break-in when new lifters or a new additive containing

camshaft

is

oil

Installed. This additive is gener-

ally available in

automotive parts stores.

4.6L Engine 1

Remove

the camshaft cover,

Fig.

2.

Remove

the camshafts for the head being

4.5L and 4.9L engines

89 Rear main seal installation tool-

worked on. 3.

on

Remove

their

the valve

litters in order,

camshaft face so

and store

that the residual oil is

4.6L Engine

retained,

>

>»Retain the

lifters in

by

marked

gasl

is

component on

ALWAYS

It

fasteners and allow

Flange Type

connections, or other deterioration which could

compartment. Inspect

Type

dissolving agent onto the fasteners for ease ot to

the exhaust manifold

at

where the header pipe

under-car parts, not to

See Figure 103

both ends

under the vehicle and inspect the system com-

or turbocharger pipe

to the

faster

near the fuel tank,

could happen,

squirt a liquid rust dissolving

agent onto the fasteners

may even be wise

flanges

pletely. Start the

damage

Before removing any

systems,

large 0-rings (doughnuts) in

attached and work your

DANGEROUS

mention yourself.

Slip Joint

Before removing any

100

resulting in

may be

cutting torch

at the very least, accidents

compo-

to separate the

hot exhaust

components.

Fig.

and

on the com-

to lap

loosen the

to

use a hacksaw

fails,

Fig.

103 Example

type system

of a

common

slip joint

ENGINE AND ENGINE OVERHAUL

3-26

ENGINE RECONDITIONING

Anything that generates heat and/or

With

ited)

tremendous amounts

engine and heat

around the spark plug

tion

created by friction and

is

reduces the amount

you can have an

bustion.

system

either

If

will

is

and com-

friction

into the

No

spark plug hole

1

Check

If

you do not

Be careful not

to

crossthread the sparic plug

hole.

and

drain, flush,

refill

the radiator,

in

conned

it

filter:

if

changed

not

is

it

often

laden with contaminates and

your

to

enough

oil

and

becomes

it

wear.

at a specific

oil

Repeat the

of

methods

Compare

1 1

An

valve seats.

tions

Excessive

engine

pump

ing cylinder pressure

may

indicate

worn piston

uses no more than one quart

rings,

worn valve

75 percent

every 1000

of oil

is in oil

or

12.

more

in less

than 1000 miles should

for oil leaks.

II

any

would be 113

psi

psi

compression

lest.

rises after

adding

means

oil,

it

If

If

A

fuel

over an extended period are

engine wear

Worn

oil

mileage measured

all

and

if

in

is

is

oil

cold pressure

doesn't help raise

Change and

well

is

the

oil.

was lower than making sure

component

pump

wear,

crankcase, too high of an

pressure

relief

compression

^e .'..

,,.:

all

oil

of

determined

,-. :;j5t make

It

more

It

talces slightly

is

largely a Is

s being put into

would

m the crankcase.

lers

il

is

rebuilt'

worth keeping' Would

of

is

OFF

Disable ttw ignition system.

it

If

il

the car

be less

yoursell ot buy a used

On

Ihe other hand,

you have considered

and more, and have

still

it

is

all

decided

then ensure engine, then

it

gel

buy a new engine, have your engine

be simpler and less expensive

It

Is

it

lime to decide

lo

buy

these mai-

lo rebuild the

how you

will

charged the engine to normal operating

temperature, then shut Ihe engine 3.

lo

by a pro. retxiHd

another car' oil is

worth

subiedive matter and one

Ihe engine a popular one, or

engine from a salvage yard?

ettort to obtain a

sure that the proper amount and vis-

is fully

your engine

is

an obsolete model'' Are pans available' Will

more accurate reading.

Warm-up

that

some decisions The

each cylin-

rebuilt

2

viscosity or a faulty

possible

expensive

the battery

i

i

valve

question of whether or not an engine

the spar1( plug hole. Although

cosity of engine

too low High

Buy or Rebuild?

accurate than the type you simply hold against

worth the

is

low,

is

worn

»K screw-in type compression gauge is

is

t.

related problems,

If

personal worth

It

Ihe engine

oil in

use the proper grad'

to

or oil viscosity that

acceptable gas mileage once

Make

the

If

the specification,

pressure readings could be caused by an overfillec

com-

der will help locate the problem

1

low. check

pressure readings could be attributed

oil

oil level,

rebuilding

longer lo use.

is

above the specification, and

quantity, then repeat the test

Low

L

piston rings, scored or

of the

pressure reading to

indicators of internal

burnt valves, and worn valve seats are

A check

oil

the reading

If

leakage past the head gasket Oil

cylinder bores, blown head gaskets, sticking or

culprits

hoi

you may have the wrong viscosity

low

needed), or

that cylinder

any two adjacent cylinders

Ihe addition of

pression, there

Compare your

7

internal

or

may

the pressure remains low, the valves

compression

noticeable lack of engine power, excessive

consumption, and/or poor

and

that the cylinder's

head gasket may be blown near

the

See Figure 104

com-

damaged

will feel

the oil pressure reading again with the

that given in the chart.

the compression

not be seating properly (a valve job

>

Check

the cold pressure reading against the chart.

(779 kPa).

piston rings and/or cylinder bore are

worn.

Ihe engine until normal operating tem-

reached (upper radiator hose

is

the hot reading

repeal the

to run the

rpm. so check Ihe specifica-

OFF

(1034 kPa), then

(779 kPa).

if

when cold

the oil pressure reading

at a specified

Run

6

your highest read-

Ihe cylinder through the spark plug hole

present, have

COMPRESSION TEST

if

psi

a cylinder exhibits an unusually low

If

oil into

them fixed before determining how much oil is consumed by the engine, especially blue smoke is not visible at the tailpipe.

was 150

il

to idle

il

engine hot and record the number Turn the engine

within 75

pression reading, pour a tablespoon of clean engine

leaks are

oil

of that

than113

condition. Engines that use one

good

be checked

is

Therefore, the lowest reading cylinder should be no less

quart of

the lowest reading cylinder

reading cylinder. For example,

Check

5

percent of the pressure recorded for the highest the

4

perature

failures-

guides, and/or valve seals. Generally, an engine that

miles

if

pressure gauge and.

oil

engine and allow

warm).

com-

of oil in the

smoke from

area and/or bluish

air intake

tailpipe

oil

consumption, evidence

oil

com-

of

pression pressures are considered within specifica-

pressure test can warn you of

oil

possible engine bearing, or

Slarl the

tions.

first.

the highest readings from each

cylinder to that of the others. The indicated

head gaskef(s), valves, and

rings, cylinder bores,

same number

pression strokes and/or time as the lest

a mechanical

3

engine

on each cylinder, cranking

for evaluating

A compression

Following the manufacturer's instructions,

and record the number. You may need

on the gauge.

test

require

rpm

necessary, a tachometer to the engine

crank the

to

may

specifications

pressure sending unit

conned

posi-

compression strokes

Ihe engine approximately the

There are a number

can reveal the condition of your pistons, piston

oil

dash-mounted gauge) A tachometer may

some

(approximately 5 seconds of cranking) and record

and 10.

first

at least five

the highest reading

the condition of your engine.

OFF

the

use the remote starting switch

engine through

unable to properly

is

lubricate the engine. This increases friction

the sending unit

at

With the engine cold, locale and remove the

2 in

can extract tion,

from the coolant. The same applies

pressure

oil

running the engine 1

a remote starting switch to Ihe

With the ignition switch

9.

thereby reducing the amount of heat

proper

also be needed, as

According to the tool manufacturer's

the proper intervals,

at

begin to accumulate

will

for

installed

starting circuit.

deposits

blown

is

pressure gauge (as opposed to relying on a factory

instructions,

your cooling system

droplets

oil

a head gaskei

if

passage with an externally mounted mechanical

8.

your vehicle.

cooling system

PRESSURE TEST

OIL

of

lite

from cold

or

be evidence of water

droplets on Ihe engine dipstick and/or

until the lifting is

not maintained, a break-

be inevitable. Therefore, you can see how

regular maintenance can affect the service

warm-up

may

weather driving There

snug.

encountered by the

of friction

Ihe tailpipe,

alarmed by the normal white smoke emitted from

in the

screw-in type compression gauge

Install a

7.

fric-

for this, or

smoke from

problem However, don't be

assistant fully depress Ihe accelerator pedal

parts inside the engine, while the cooling

system reduces heat created by

down

open

the accelera-

combined

the combustion chamber,

ot this

the tailpipe during engine

You can block

throttle) position.

tor linkage

system

oiling

remove the spark

Set Ihe throttle plate to the fully open (wide-

6.

open

combus-

ports, then

symptoms

are

plugs.

engine has systems

reduce the effects of heat and

to help

and provide added longevity. The

moving

lim-

rotating parts inside the

tion of the fuel. However, the

designed

is

encoun-

of both; friction is

moving and

tered by the

span

its life

in

with blue or constant while

Thoroughly clean the cylinder head area

5.

mind, a running engine generates

this in

and coolant

the spark plug

all of

wires from the plugs.

friction will

eventually burn o( wear out (lor example, a light

bulb generates heat, therefore

Label and disconnect

4.

Determining Engine Condition

Fig.

-rebuild

104 A screw-in type compression

gauge

Is

more accurate and easier

without an assistant

lo

use

•The

it

editors at CtiiHon leal ttut

most engine

maclilning should be performed by a proles

ENGINE AND ENGINE OVERHAUL machine shop. Don't think of it as wastmoney, rather, as an assurance that the job

sjonal ing

has been done right the

many expensive and

time. There are

first

specialized tools required

perform such tasks as boring and honing an

to

engine block or having a valve job done on a

tvluch of the

assembly work (crankshaft, bear-

and other components)

ings, piston rods,

specifically formulated for this

used, but engine

well

is

within the scope of the do-it-yourself mechanic's tools

and

You

abilities.

will

have

to

decide

depth of involvement you desire

self the

in

lube

an

ings will

CLEANING

maximum

come from performing

The tools required

disassembly, assembly and installation of the

A complete

of the

above tasks.

new ones and

machining the non-moving wearing surfaces t)lock

and heads. Unfortunately,

may

this

have been damaged or worn, but

machined undersize

for a

may

it

is

wiser to replace only

those parts which are really needed, and, sible, repair the

break the engine

more expensive ones.

down

into

nents: the cylinder head will

if

Later

pos-

we

We

parts to replace during a rebuild

in-depth

IVIicrometers

•

Jaw and screw-type

overlooked

Scraper Valve spring compressor

•

Ring groove cleaner

•

Piston ring expander and compressor

Most

•

Ridge reamer Cylinder hone or glaze breaker Plastigage*-

of

from a

can be rented for a one-time use supply house spe-

called

are fairly stan-

in

also a guide to acceptable

engines, due to

along with specific details concerning your particu-

•

maximum In

performance,

most instances

for the do-it-yourself

it

mechanic

is

to

reliatiility

more

and

profitable

remove, clean

and inspect the component, buy the necessary and

deliver these to a

shop

for actual

parts

machine work.

is

105 Use a gasket scraper

to

etc.).

Use

of a wire

NOT RECOMMENDED on any aluminum

You should always wear eye protection dur-

any cleaning process involving scraping, chip-

for

low weight. Observe the

its

use

alternative to the

fol-

is to

mess and hassle drop them

garage or machine shop. They

all

of the parts for a

of cleaning

off at a local

will,

more than

have the necessary equipment

likely,

clean

Remove

•

all

aluminum

nominal

to properly

fee.

parts (identification tag,

compounds

Always wear eye protection during any

to the tanking.

lightly with

engine

oil

or

before installation, to prevent

cleaning process involving scraping,

Remove any

Never overtighten bolts or spark plugs espe-

cially in

aluminum

the engine,

frictional contact

provide lubrication

any parts

that will

must be prelubed

at initial start-up.

Any product

remove

the old gasket material from the mating

Fig.

surfaces

remove the piston

106 Use a

ring

expander

rings

oil

galley plugs, freeze plugs and/or

pressed-in bearings and carefully wash and degrease

threads.

When assembling be exposed to

cliip-

ping, or spraying of solvents.

to

all

of the engine

and etc.,

bolts.

tool to

components including

the fasteners

Small parts such as the valves, springs,

should be placed

in a

metal basket and allowed

^

to soak.

Fig.

using a

dations given by the manufacturer of the tool and/or

An

Always coat threads

seizure.

life.

require If

critical

ping, or spraying of solvents.

from engine parts prior

Competent and accurate machine shop services ensure

may

with a wire brush.

hot tank solution will eat the aluminum.

etc.)

anti-seize

engine

chisel.

Never hot tank aluminum parts (the caustic

engine.

will

drill

bearing saddles, cylinder bores,

book before substi-

the front of this

lowing precautions when handling aluminum parts:

•

rebuilding practice are given and should be used

and readily available sol-

be removed using a scraper and/or cleaning

solvent.

•

your individual

tools

machined surfaces (such as the gasket surfaces,

ing

rebuilding procedures. Examples of standard

lar

cleaning process can be carried out

the parts yourself

Most engine overhaul procedures

sludge or carbon.

of

components. Always follow any safety recommen-

on each.

dard. In addition to specific parts replacement pro-

is

of the

common hand

brush is

Aluminum has become extremely popular

engine, this section

hidden by a layer

wire brush, use extreme care around any

See the information on Special Tools and the in

if

the use of a power

automotive work.

Safety Notice

the

in

away using a hammer and a hard wooden

of these tools is illustrated in

Occasionally, the use of special tools for

A crack

Old gasket material and varnish or sludge can usu-

local parts jobber or tool

cializing in

sludge

components

of the

all

solvent. Extremely stubborn deposits

most

are

oil

vents or solutions. Carbon deposits can be chipped

•

Engine stand

components

engine block or cylinder head can easily become

•

•

its

must be thoroughly cleaned. You

remove any engine varnish,

pullers

•

•

to

to insure an accurate inspection.

Engine Overhaul Tips

for

need

and/or carbon deposits from

OVERHAUL TIPS

cedures and specifications

Before the engine and inspected, they

thousandths)

tuting another tool.

discuss each component, and the recom-

mended

l\/lore

of the following:

all

and telescope gauges

•

this section, tvlany

will

two main compo-

its

and the engine block.

or

dial indicator (reading in

The use

lee.

So, as you can see, you can replace everything inside the engine, but,

A

ally

can be

it

minimal

of the

not be

cost effective. For instance, your crankshaft

some

See Figures 105, 106, 107 and 108

with

parts (pistons,

rods, cranl(Shaft, camshaft, etc.) with

require

»

be the

mounted on a universal base

of the cost

moving

will

your

of

will

will

•

rebuild or overhaul of an engine all

depend on the depth

tools found in a mechanic's tool.

work

doing these yourself.

involves replacing

an engine overhaul or

involvement. With a few exceptions, they

Depending on the particular circumstances, you may save 40 to 60 percent

for

parts replacement will

sav-

the removal,

engine and purchasing or renting only the tools required to perform the

or

Loctite'-'

TOOLS

you

clean, and ready to assemble parts, saving

you time and aggravation. Your

a pre-

(locked, but removable)

should be cleaned and coated with

properly measure wear and clearances. In to

purpose can be

recommended as

another similar, commercial non-hardening sealant.

requires expensive micrometers and gauges to

machine shop can deliver

not

installation of bolts or nuts is desired, threads

engine repair or rebuild.

cylinder head. Even inspecting the parts

addition, a

oil is

most cases.

When semi-permanent

your-

tor

in

3-27

Fig.

Use pipe cleaner type brushes, and clean

107 Clean the piston

i

using a ring groove cleaner tool, or

all

ENGINE AND ENGINE OVERHAUL

3-28

BOLT OR SCREW

DAMAGED THREADS

X^

ICCSJ911

108

Fig.

.

.

use a piece

.

of

an old ring to

109 Damaged

clean the grooves. Be careful, the ring can

Fig.

be quite sliarp

be replaced with thread repair Inserts

bolt hole threads

can

Fig.

110 Standard thread repair Insert

(lett).

Fig.

and

sparic plug thread Insert

113 Screw the

Drill

out the

damaged threads

with the specified size

bit.

Be sure

to drill

completely through the hole or to the bot-

tom

of a blind hole

passageways

in the

pis-

Ion ring grooves with a special tool or a piece ot bro-

Scrape the carbon

ring.

piston.

in this

oft of

Ihe top ol the

Vou should never use a wire brush on the

pistons. After preparing

kit,

Thread the insert

tap the hole in

all

assemblies

ol the piston

manner, wash and degrease them again.

the tap well oiled and back

remove

out fre-

it

threads ol the insert) and an installation tool

Spark plug inserts usually

This

REPAIRING

will

lot ol

and they would not have wasted any

manufacturers

and

kit

containing a vari-

inserts plus installation loots

studs Penetrating

oil

damaged

or

can be used

put

shown and

accompanying

in the series ol

in the ki!

can be repaired, as

still

Several methods o* repairing are available

damaged threads

Heli-Coil' (shown here), Keenserls'.

and Microdot' are among Ihe most widely used. involve basically the

same

principle

All

—

drilling out

stripped threads, tapping the hole and installing a

prewound

insert

—making

welding, plugging and

Two types

ol thread repair inserts are usually

supplied a standard type for most inch coarse, inch line,

metric course and metric line thread sizes and

a spark lug type to

fit

most spark plug

remove

port sizes

it

Ideally

that

Irom Ihe engine,

it's

lime to strip

it

necessary components Belore you bling the engine, you

may want

oil

start

to lake a

moment

draw some

containers to mark the locations of various

contain a selection of prewound threaded

nents and

««

is

to

to

timing cover and require the vibratio'i

be removed before

reduce the engine to the bare

Finally,

shafts

and connecting rods).

components such as

and

oil

auxiliary shafts

remove the cylinder head(s) from the

semblv instructions

lor

each component follow

later

Cylinder Head

disassem-

determine exact applications Typical thread repair kits will

may

engine block and carefully place on a bench Disas

ol all but the

some

Iront, or

front covers

and coolant

Consult Ihe individual tool manufacturer's catalog to

pictures, ot fabricate

Some

plus any other in block'

the llywheel or flexplale

you have drained Ihe

pump

Then, unfasten

remove any covers remaining on the engine

pumps, balance

you have Ihe engine on a stand, and

thai

pan

block, crankshaft, pistons

before installing the engine to the stand

assuming

alternator, etc

necessities (cylinder head(s), valve train, engine

using the stand with your

Remove

such as the water

to the engine,

hand The idea

you should place your engine

access to the engine components Follow the manu-

particular engine

a rotating pari

damper and/or crank pulley

first

on an engine stand This allords you the best

lacturer's directions lor

ol

such as the rocker arm,

Irom the vehicle, then disassemble and it

will regret not

bracket which holds a wire

little

removed during the engine removal procedure

manufacturer's instructions.

To properly rebuild an engine, you must

Now